Adjustment and protection device for solar energy heat collector

A solar collector and protection device technology, applied in the directions of solar collectors, solar collector safety, solar thermal devices, etc., can solve the problems of decreased heat collection efficiency, easy damage and rupture of glass vacuum tubes, etc., and achieves reasonable utilization, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

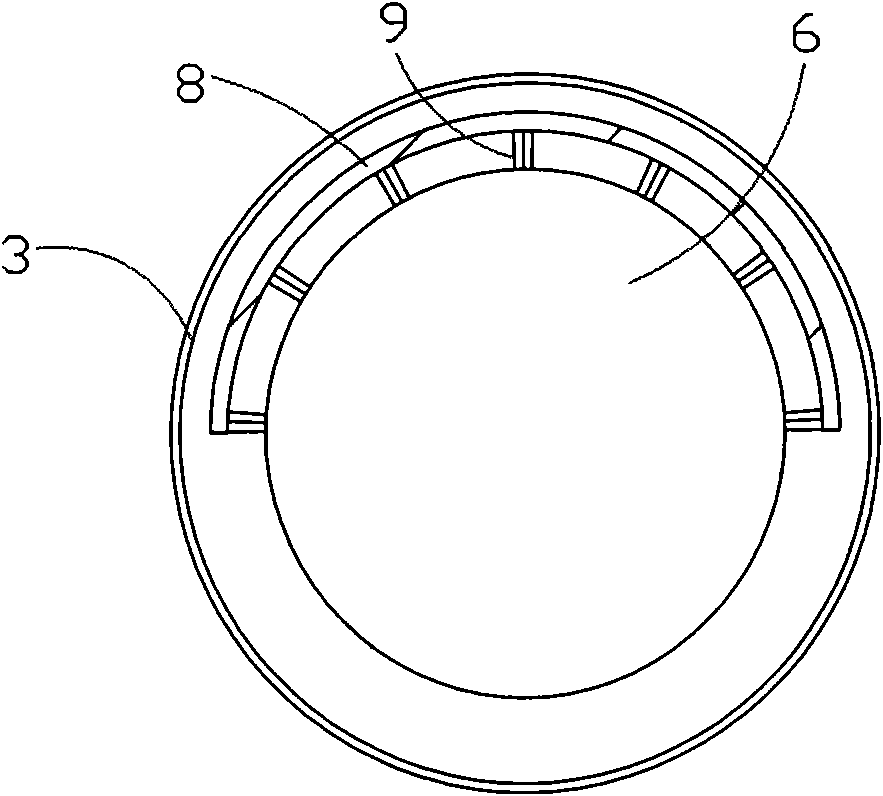

[0019] As shown in the figure, the solar heat collector adjustment and protection device involved in the present invention includes a thermal insulation water tank 1 and more than one vacuum heat collection tube 6. The vacuum heat collection tube 6 communicates with the thermal insulation water tank 1 and also includes a heat collection tube support Frame 4, heat collecting tube protective cover 7, the two ends of each vacuum heat collecting tube 6 are respectively fixed on the respective corresponding heat collecting tube support frames 4, and the cover body 8 of the heat collecting tube protective cover 7 is mounted on the vacuum heat collecting tube 6, the cover 3 of the heat collecting tube protective cover 7 is hinged on the connector 2 of the vacuum heat collecting tube 6.

[0020] The cover body 8 of the heat collecting tube protective cover 7 has a semicircular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com