Tempering-resistant air adjusting type gas stove with upper air inlet

A technology of gas cooker and upward air intake, which is applied in the direction of gaseous heating fuel, gas fuel burner, burner, etc., and can solve problems such as inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

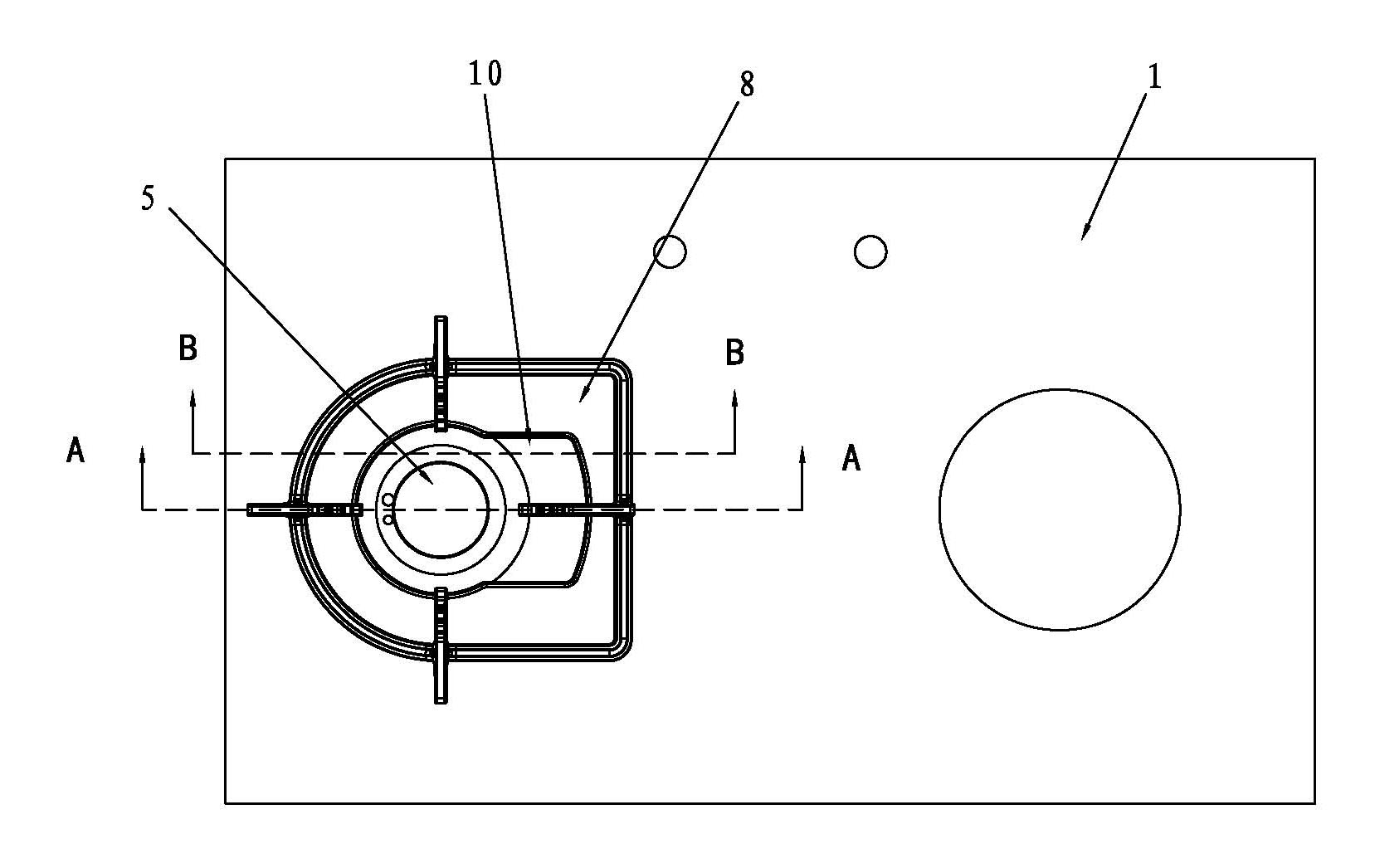

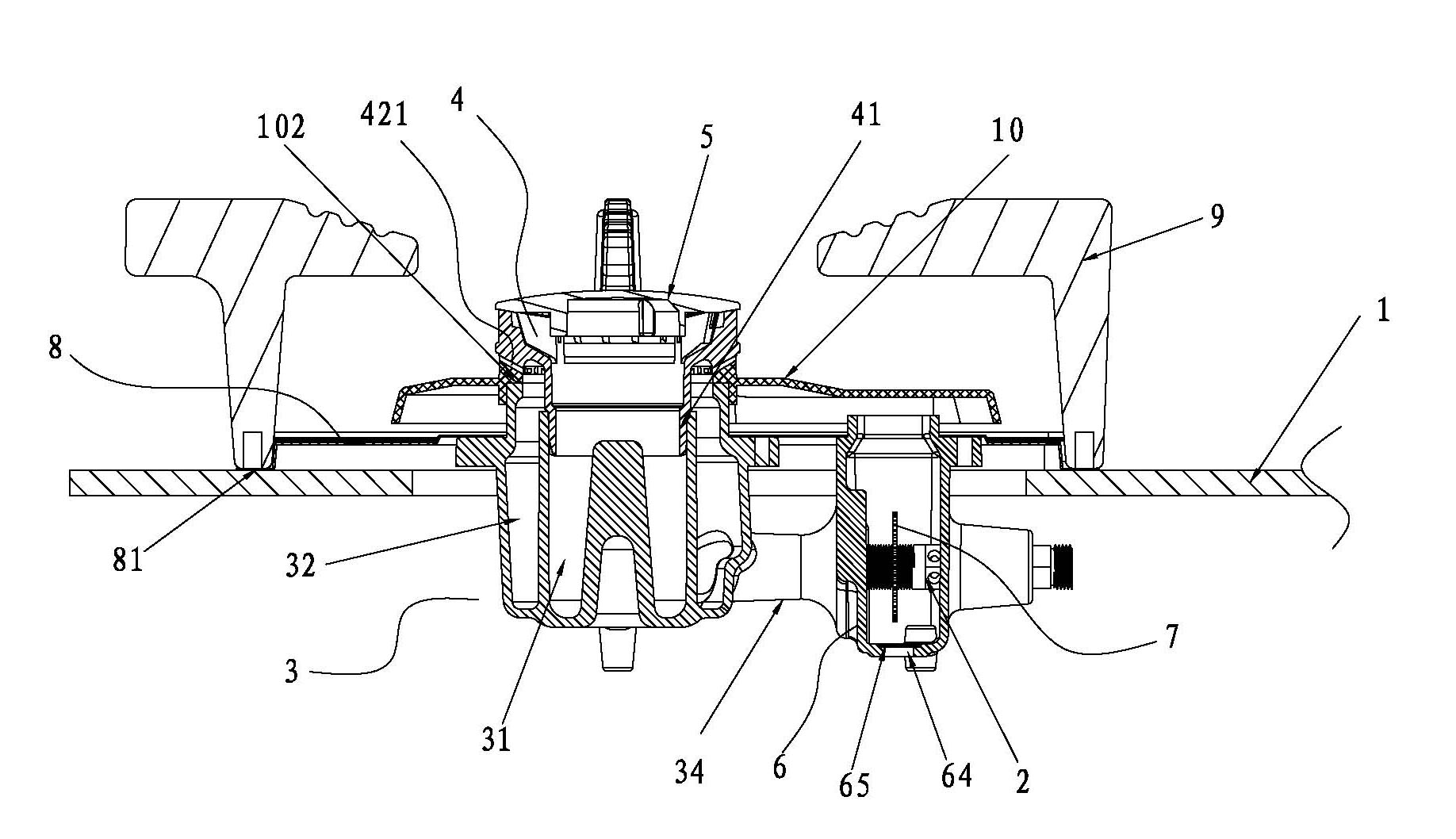

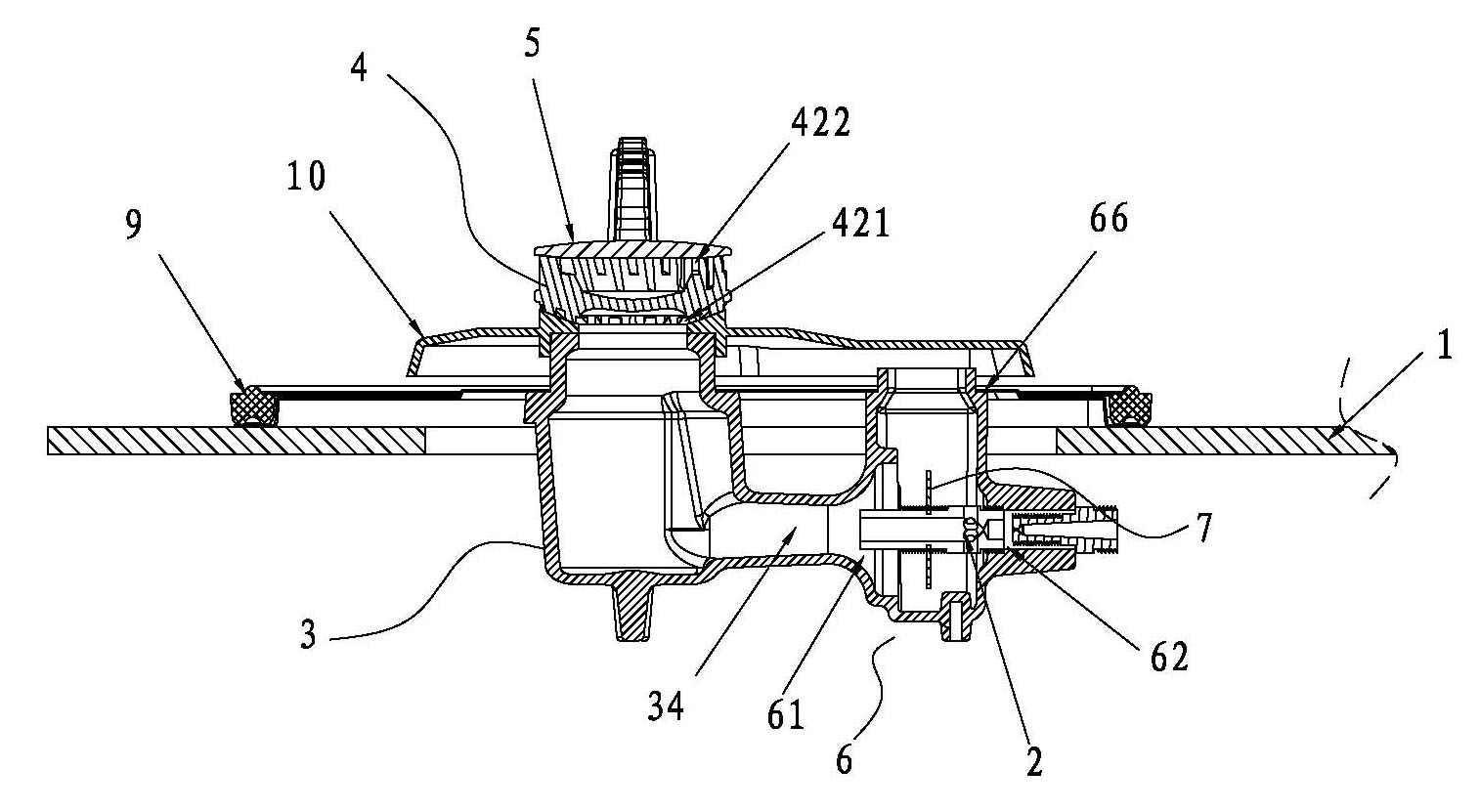

[0026] Such as figure 1 , figure 2 , image 3 As shown, a backfire-proof updraft gas cooker includes a panel 1, a burner and a nozzle 2, and the burner includes a burner 3, a fire distributor 4 and a fire cover 5, and the burner 3 includes a preheater Mixing cavity and injection tube; also includes an air cavity 6 with an upper opening

[0027] Air outlet 61 and air inlet 62 are respectively arranged on the front and rear side walls of air chamber 6, and air outlet 61 and air inlet 62 are on a straight line; 62 , the air inlet end of the nozzle 2 is threadedly matched with the air outlet hole 62 , and the air outlet end of the nozzle 2 is opposite to the air outlet hole 61 ; the upper opening of the air cavity 6 passes through the panel 1 . A cover plate is arranged above the upper opening of the air cavity 6 , and there is a primary air intake gap between the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com