Gear rack vertical ship lifting device

A vertical ship lift and rack and pinion technology, applied in the field of ship lifts, can solve the problems of a heavy nut and screw safety system, passengers cannot be evacuated in time, and high manufacturing costs, achieving high market promotion and application value, novel design, and engineering small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

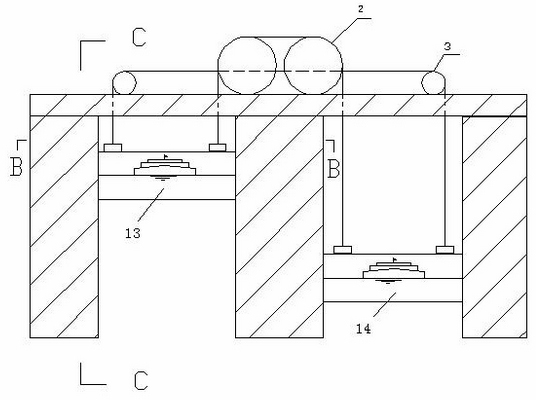

[0039] As shown in the figure, the rack and pinion vertical ship lift consists of a ship lift compartment, a ship compartment, a rack and pinion mechanism and a safety mechanism. It is characterized in that the ship lift compartment is a symmetrical double Ship compartment, the compartments 13 and 14 in the symmetrical two compartments are identical, and the two identical compartments are connected together with wire ropes and sheave groups, and the direction of motion of the two compartments is opposite. Counterweight each other. The cabins in the two compartments are provided with two working doors, the downstream side working door 1 and the upstream side working door 5 . The cabins in the two cabins are connected into one with two groups of inner sheave groups 2,4 and one group of outer sheave groups 3. The gear of the described rack and pinion mechanism has two gears, one of which is a power gear 11 driven by a power unit 12, and the other gear is a braking gear 7 driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com