Cracking furnace for producing ethylene by cracking hydrocarbon steam

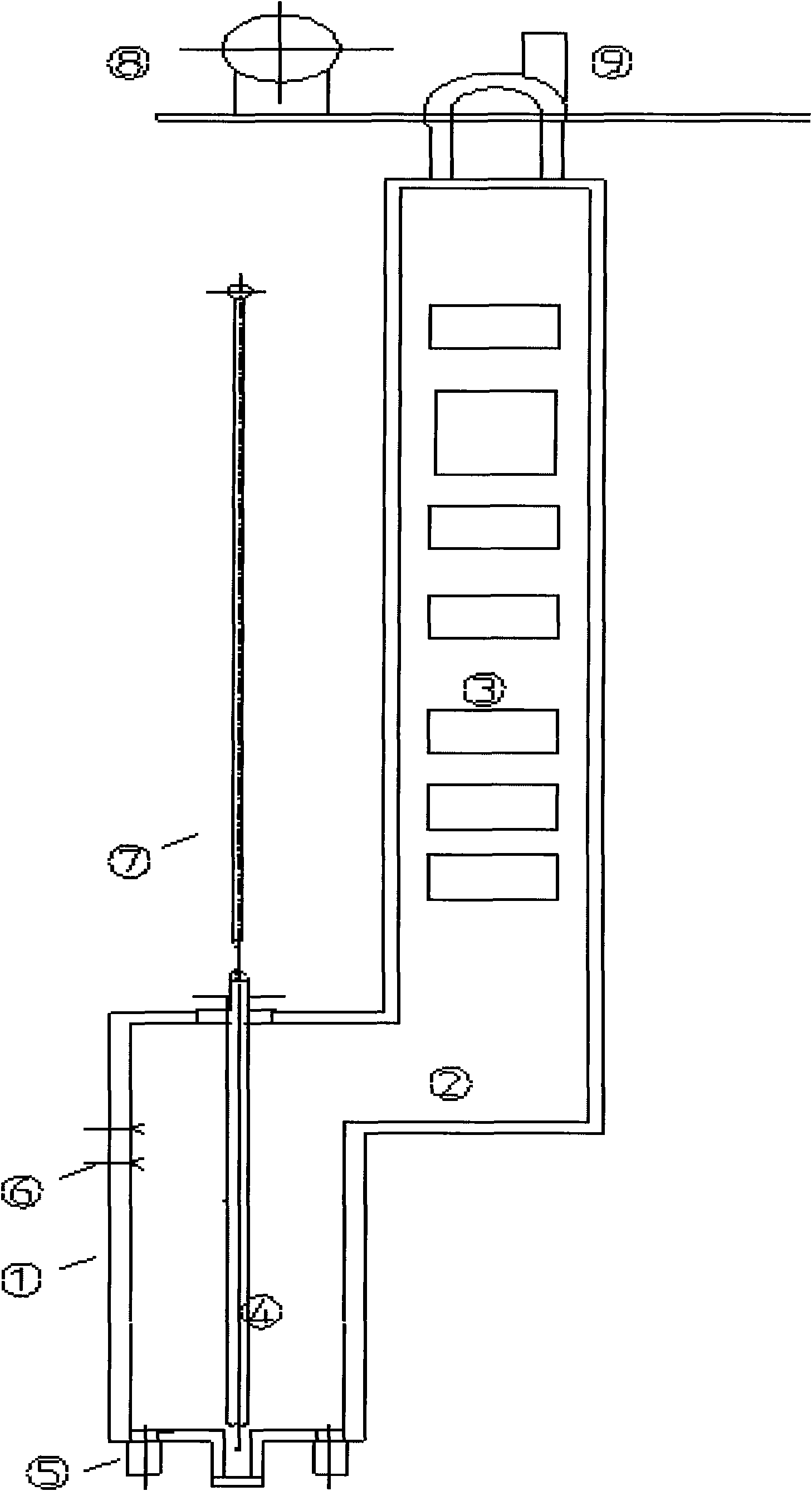

A technology of cracking ethylene and cracking furnace, which is applied in the field of petrochemical industry. It can solve the problems of furnace tube bending, poor flexibility of large-diameter bent tubes, and movement with the second-pass tube, so as to achieve the force balance of the furnace tube and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

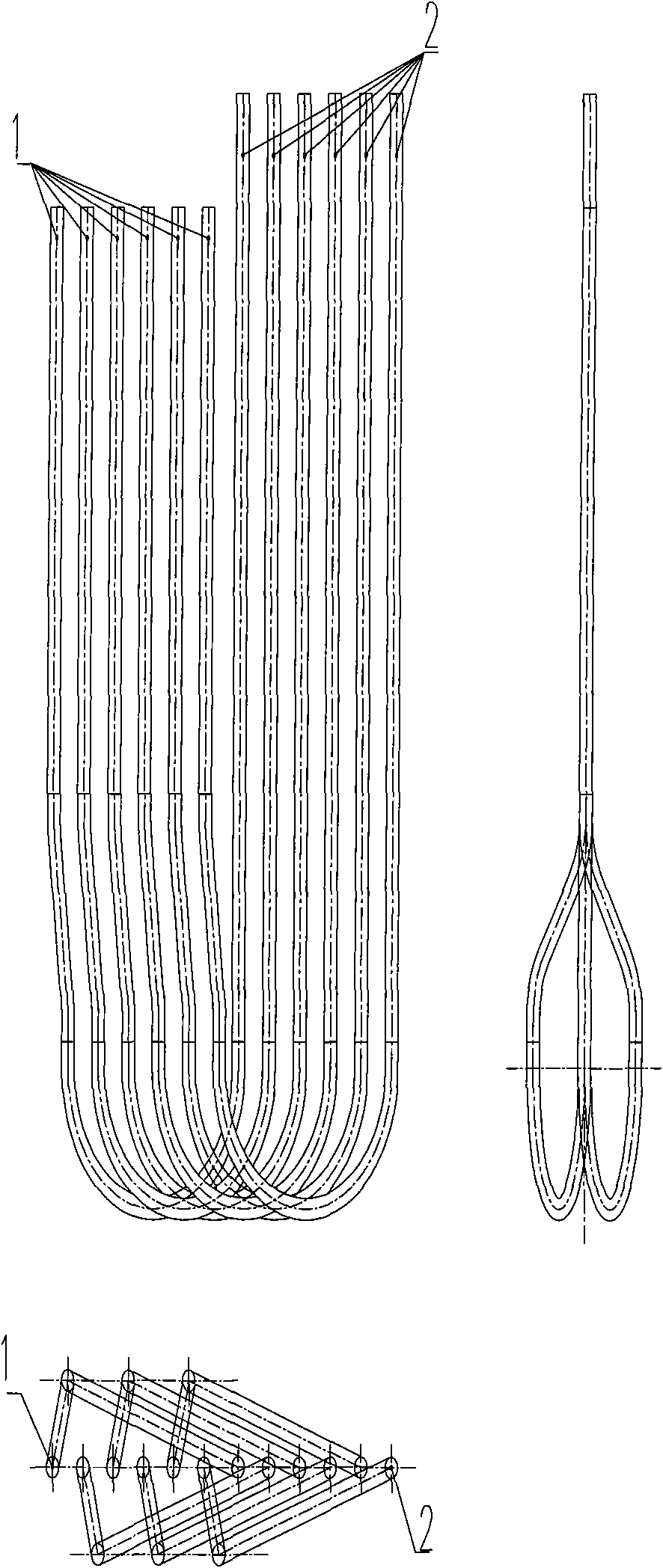

[0055] Such as Figure 4A and Figure 4B As shown, two-pass 2-1 type branch variable-diameter furnace tubes are used, in which the first-pass furnace tubes are arranged on both sides of the second-pass furnace tubes, the number of second-pass furnace tubes is 8, and the total number of first-pass furnace tubes is There are 16 tubes, and 8 tubes are arranged on both sides of the second-pass tube.

[0056] The furnace tubes of the first pass and the second pass are in the same plane. The two same symmetrical bent pipes of the connecting piece between the first and second pass furnace tubes of each radiant furnace tube are in the same plane and form an included angle with the furnace tube plane. A set of symmetrical bent tubes of radiant furnace tubes is projected as a set of parallel lines in top view. There is an S-bend at the first tube on both sides of the second tube and bends out of the furnace tube plane. The angle between the top view projection and the furnace tube pl...

Embodiment 2

[0058] Such as Figure 5 As shown, the 2-1 type two-pass branch variable-diameter furnace tube is used, in which the first-pass furnace tube is arranged on both sides of the second-pass furnace tube, the number of second-pass furnace tubes is 8, and the total number of first-pass furnace tubes is There are 16 tubes, and 8 tubes are arranged on both sides of the second-pass tube.

[0059] The second-pass furnace tube is in a vertical plane, and the two planes where the first-pass furnace tube is located form an identical angle with the plane where the second-pass furnace tube is located and take it as a plane of symmetry. The two identical symmetrical bent pipes of the connecting piece between the first and second pass tubes of each radiant furnace tube are in the same plane and form an included angle with the plane of the second pass furnace tube. A set of symmetrical bent tubes of radiant furnace tubes is projected as a set of parallel lines in top view. The first-pass tube...

Embodiment 3

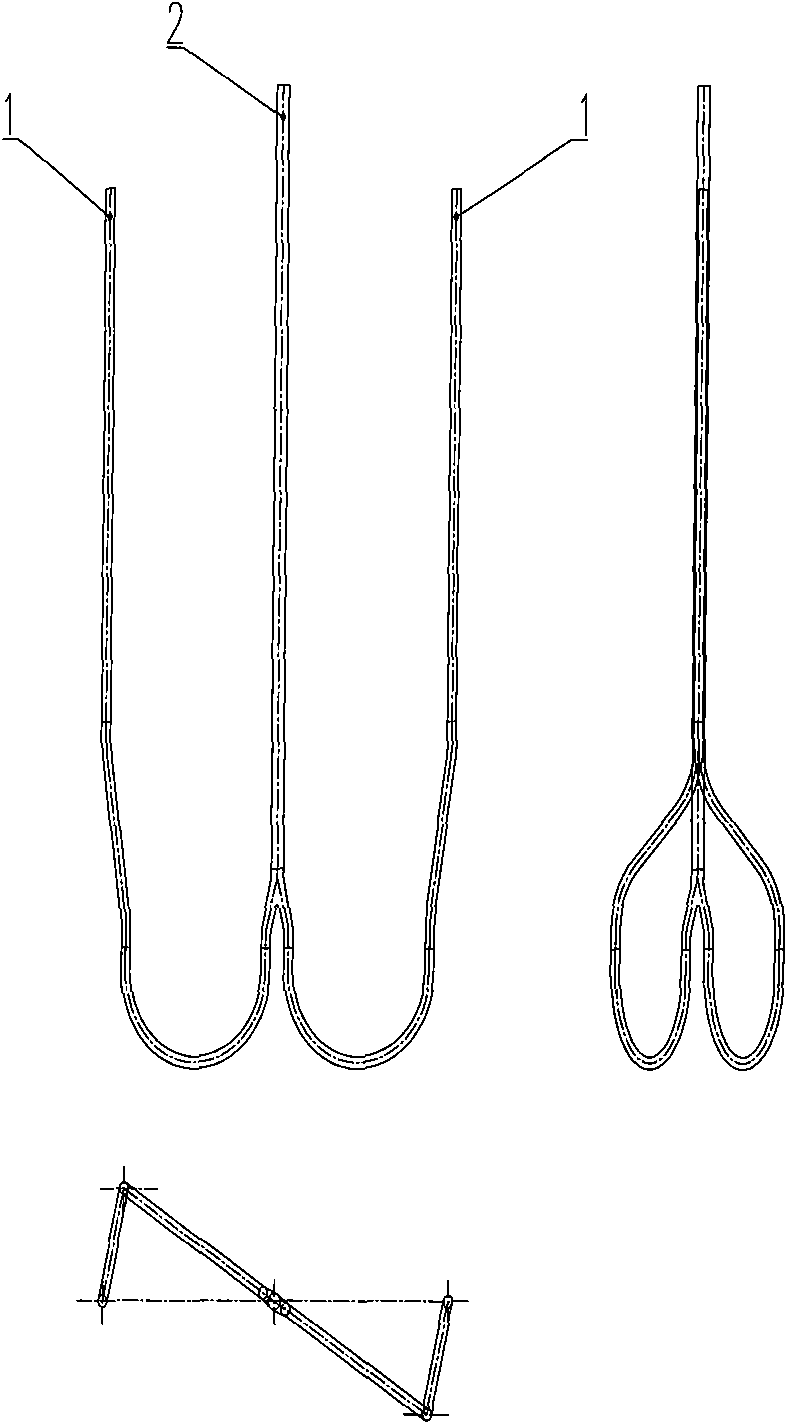

[0062] Such as Figure 6 As shown, two-pass 2-1 type branch variable-diameter furnace tubes are used, in which the first-pass furnace tube is arranged on one side of the second-pass furnace tube, the number of second-pass furnace tubes is 8, and the total number of first-pass furnace tubes is For 16.

[0063] The furnace tubes of the first pass and the second pass are in the same plane. The two planes where the two identical symmetrical bends of the connecting piece between the first and second pass furnace tubes of each radiant furnace tube are located form the same angle with the plane of the second pass furnace tube and take it as a plane of symmetry. The included angle depends on the specific furnace The number of pipes, pipe diameter and arrangement of pipe rows are determined. The first pass tube has two S-bent tubes that bend out of the furnace tube plane respectively, and the angle between the top view projection and the furnace tube plane is determined according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com