Ultrasonic coupled membrane bioreactor for treating difficultly-degradable organic waste water

A technology of membrane bioreactor and ultrasonic coupling, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problems of low treatment efficiency and long residence time, etc. Achieve the effect of reducing operating costs, slowing down membrane fouling, and realizing online cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

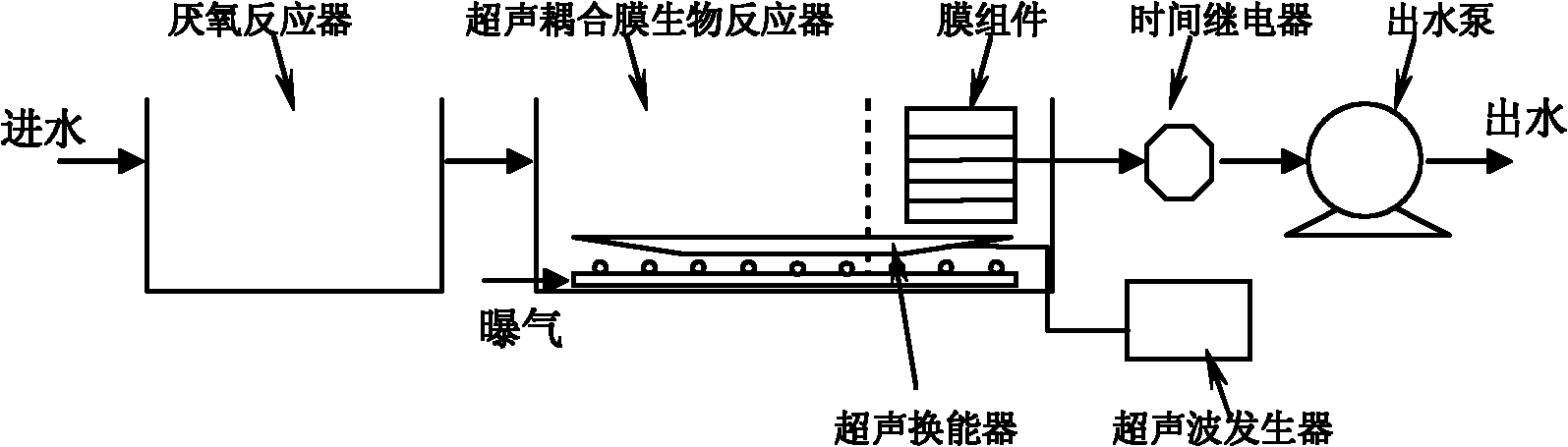

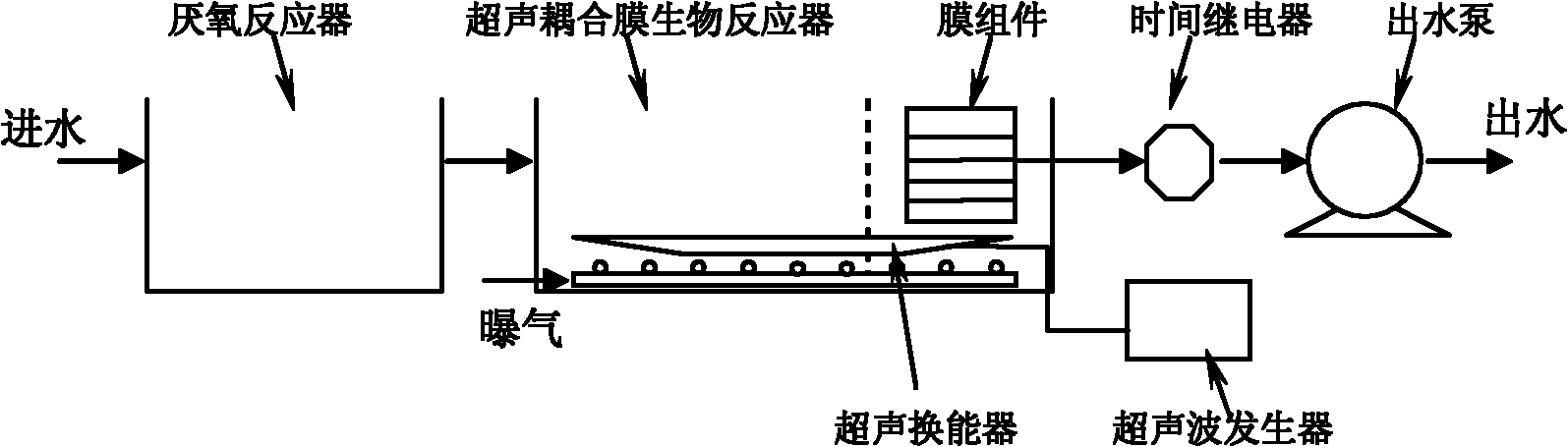

[0013] Example 1: Process flow for treating high-concentration refractory organic wastewater.

[0014] Such as figure 1 As shown, for high-concentration refractory organic wastewater, it first enters the anaerobic reactor. On the one hand, part of the organic pollutants in the wastewater are removed to reduce the concentration of the wastewater. On the other hand, the structure of refractory organic substances is partially destroyed by anaerobic action. , improve its biodegradability, and create conditions for further aerobic treatment; then the wastewater enters the ultrasonically coupled membrane bioreactor, and an ultrasonic transducer is installed at the bottom of the membrane bioreactor, which is also connected to the ultrasonic generator, and the The high-frequency oscillation signal sent by the ultrasonic generator is converted into high-frequency mechanical oscillation and propagated into the ultrasonic-coupled membrane bioreactor. The ultrasonic frequency is 10-35KHz,...

Embodiment 2

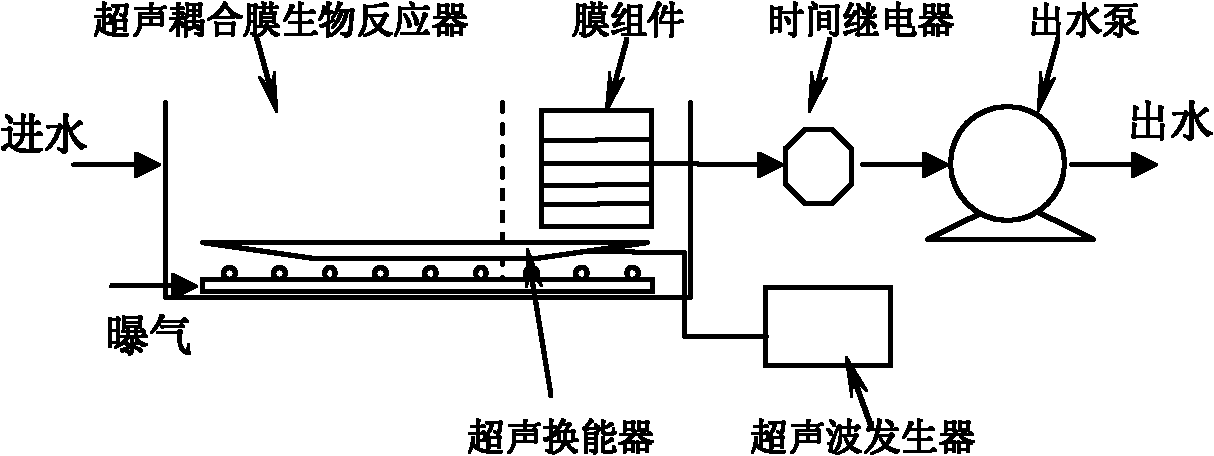

[0015] Example 2: Process flow for treating medium and low concentration refractory organic wastewater.

[0016] Such as figure 2 As shown, for medium and low concentrations of refractory organic wastewater directly into the ultrasonic coupling membrane bioreactor, an ultrasonic transducer is installed at the bottom of the membrane bioreactor, and the transducer is also connected to the ultrasonic generator, and the ultrasonic generator emits The high-frequency oscillation signal is converted into high-frequency mechanical oscillation and transmitted to the ultrasonic coupling membrane bioreactor. The frequency of the ultrasonic wave is 10-35KHz, the ultrasonic irradiation intensity is 0.05-0.2W / cm2, and the irradiation time is 2-20min. The irradiation period is 12-48 hours; the sludge concentration of the coupling reactor is 2-10g / L. Under the joint strengthening effect of ultrasonic wave and ultrafiltration membrane, the degradation rate of refractory organic matter can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com