Method for crystallizing sodium thiosulfate pentahydrate

A technology of sodium thiosulfate pentahydrate and sodium thiosulfate, which is applied in the direction of thiosulfate/dithionite/polythionite, etc., which can solve the problem of small effective volume capacity of batch crystallizers and product batch differences , large floor space and other issues, to achieve stable product quality, no batch-to-batch differences, and improved production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

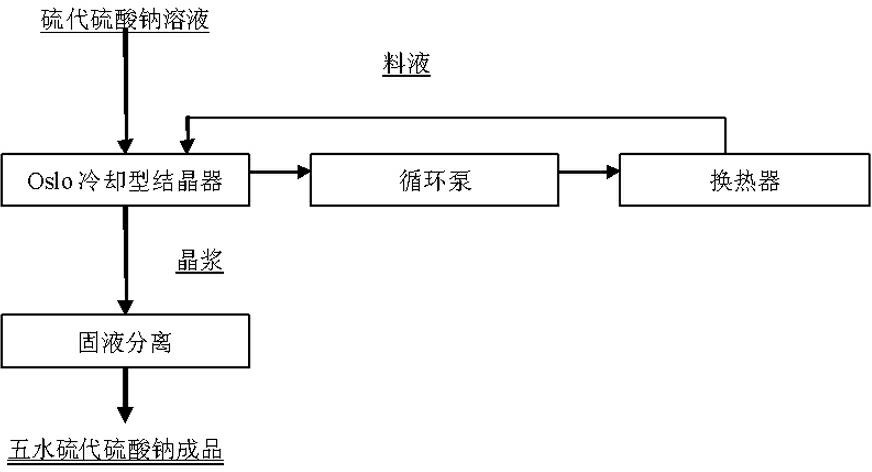

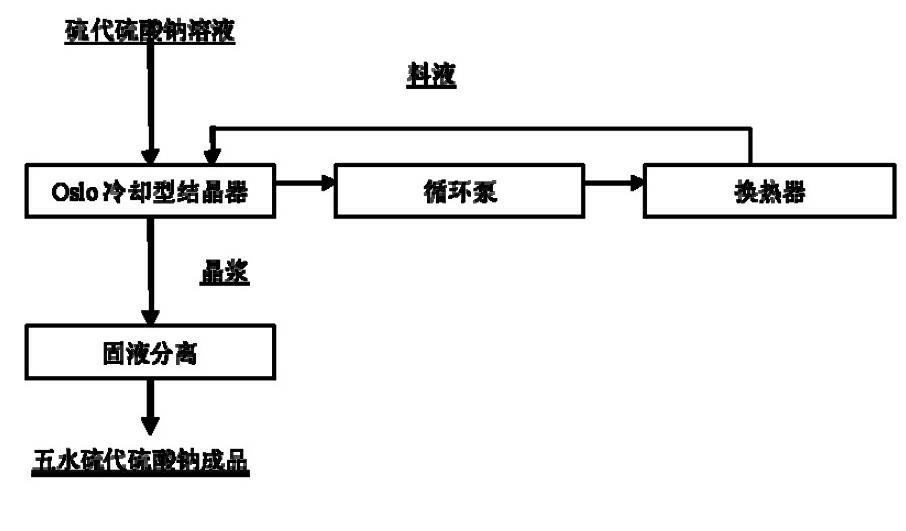

[0012] As shown in the figure, the concentration of 49Be' sodium thiosulfate solution at 80kg / m 3 The rate of h is continuously sent to the Oslo cooling crystallizer, and then sent to the heat exchanger for cooling and cooling by a circulating pump; when the temperature drops to the saturation temperature (41-42°C), seeds with a particle size of 2 mm are added at one time, and the crystallization time is 18 hours. , continue to cool down to 35-36 ° C, start to discharge the crystal slurry continuously; the discharged crystal slurry is separated from solid and liquid to obtain the finished product of sodium thiosulfate pentahydrate. The purity of the product is 99.7%, the particle size is greater than 3mm, and the production capacity is 23kg / m 3 h.

Embodiment 2

[0014] As shown in the figure, the concentration of 47Be' sodium thiosulfate solution at 60kg / m 3 The rate of h is continuously sent to the Oslo cooling crystallizer, and then sent to the heat exchanger for cooling and cooling by a circulating pump; when the temperature drops to the saturation temperature (37-38°C), a seed crystal with a particle size of 3mm is added at one time, and the temperature continues to drop to When the temperature is 30-31°C, the crystal slurry starts to be discharged continuously, and the crystallization time is 20 hours. The discharged crystal slurry is separated from solid and liquid to obtain the finished product of sodium thiosulfate pentahydrate. The product purity is 99.6%, the particle size is greater than 4mm, and the production capacity is 20kg / m 3 h.

Embodiment 3

[0016] As shown in the figure, the sodium thiosulfate solution with a concentration of 50Be' was added at 100kg / m 3 h is continuously sent to the Oslo cooling crystallizer, and then sent to the heat exchanger by a circulating pump for cooling and cooling; when the temperature drops to the saturation point (43-44°C), seed crystals with a particle size of 4mm are added at one time, and the temperature continues to drop to 37 At -38°C, the crystal slurry began to be discharged continuously, and the crystallization time was 15 hours. The discharged crystal slurry is separated from solid and liquid to obtain the finished product of sodium thiosulfate pentahydrate. The purity of the product is 99.5%, the particle size is greater than 5 mm, and the production capacity is 25 kg / m 3 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com