Volume quantitative filling machine

A filling machine and volume technology, applied in packaging and other directions, can solve the problems of impossible large-scale adjustment, increase machine cost, inconvenient disassembly and assembly, etc., and achieve the effect of improving efficiency and automation, accurate metering, and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

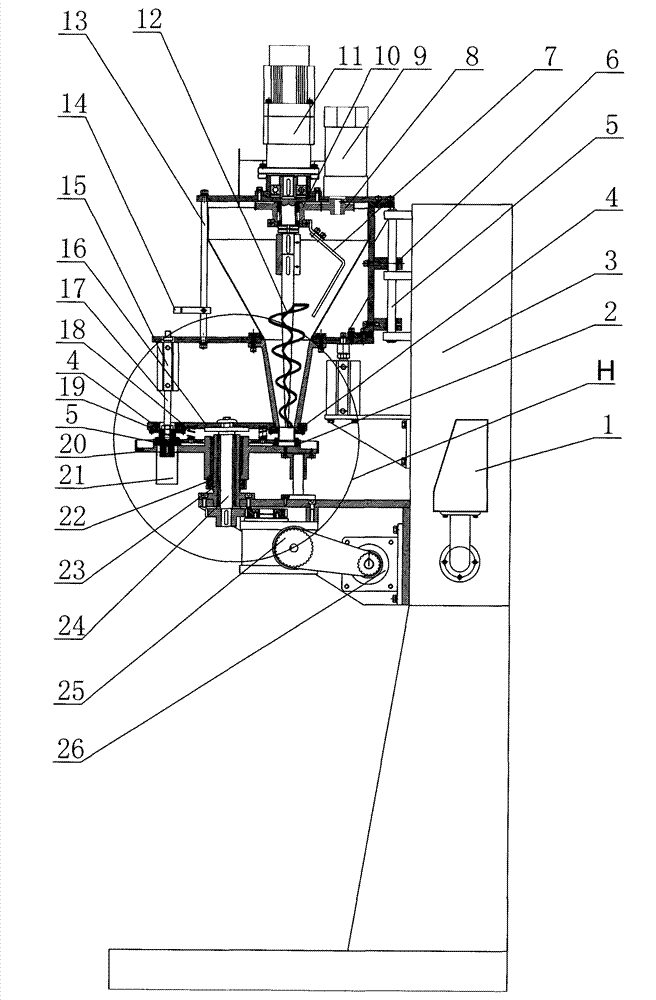

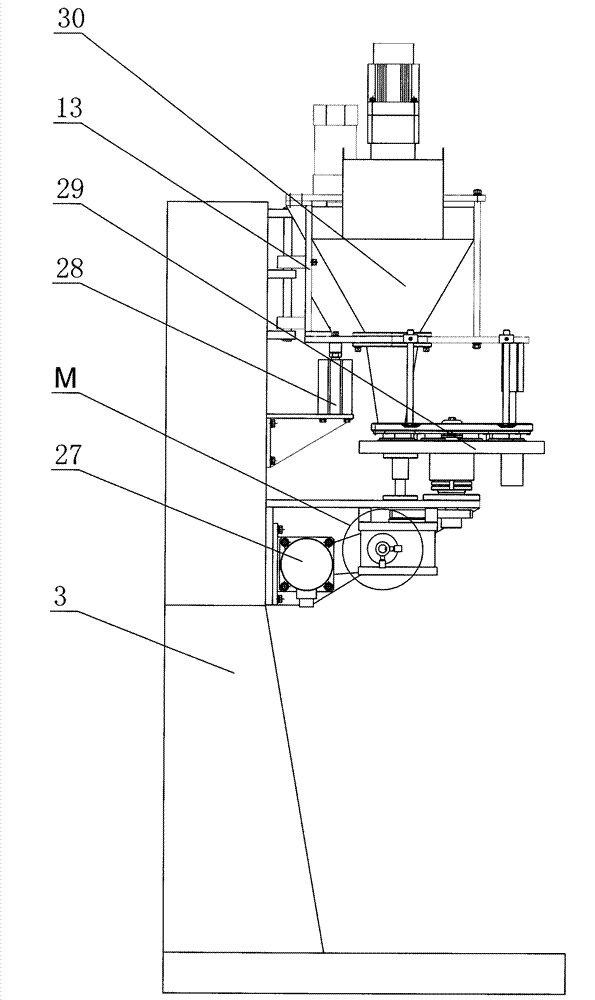

[0023] With reference to accompanying drawing, this volume quantitative filling machine comprises body 3, feeding device, stirs material device and quantitative device 29, and described feeding device comprises hopper 30, feeding screw rod 12, stirring paddle 7 and screw drive motor 10 and Stirring paddle drive motor 9, described hopper 30 is the cone shape of up big and down small, simultaneously, described feeding screw rod 12 is also in the shape of up big and small cone shape, and described feeding screw rod 12 and described screw rod driving motor 10 transmission connection, the stirring paddle 7 is transmission connected with the stirring paddle drive motor 9, the stirring device has a first cylinder 15, a mobile frame 13 is installed on the body 3, the feeding device and the stirring device The devices are all installed on the moving frame 13, that is, the hopper 30 of the feeding device and the screw drive motor 19, the stirring paddle driving motor 9 and the first cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com