Apparatus for the shaping of plastics material pre-forms with a clean room

A technology for plastic parisons and clean rooms, applied in packaging sterilization, irradiation, chemistry, etc., can solve the problems of folding bellows purification or sterilization difficulties, and achieve good purification or sterilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

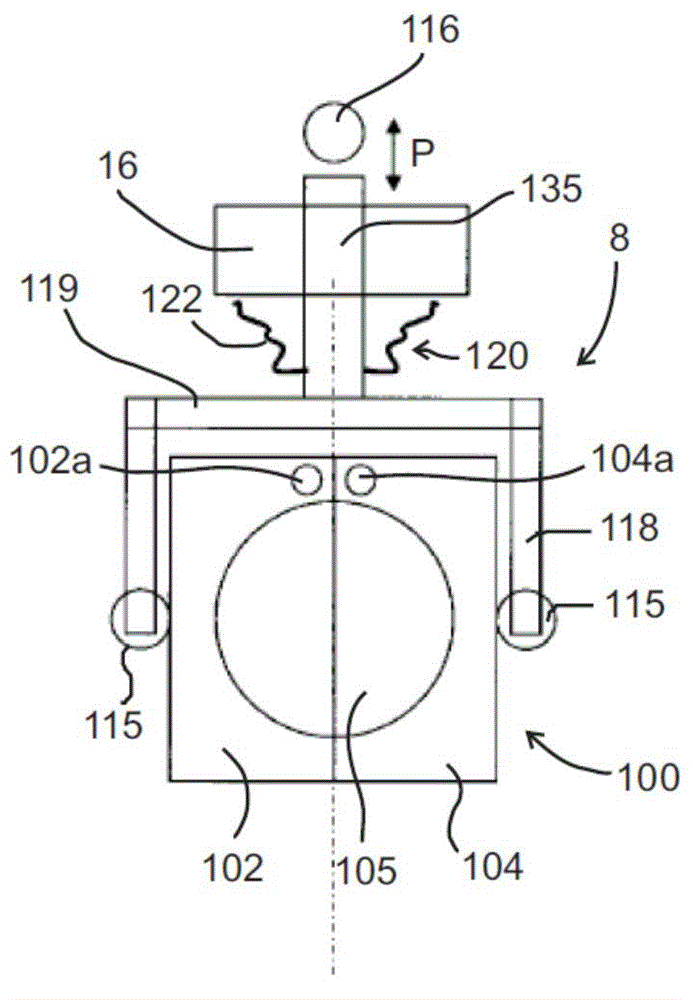

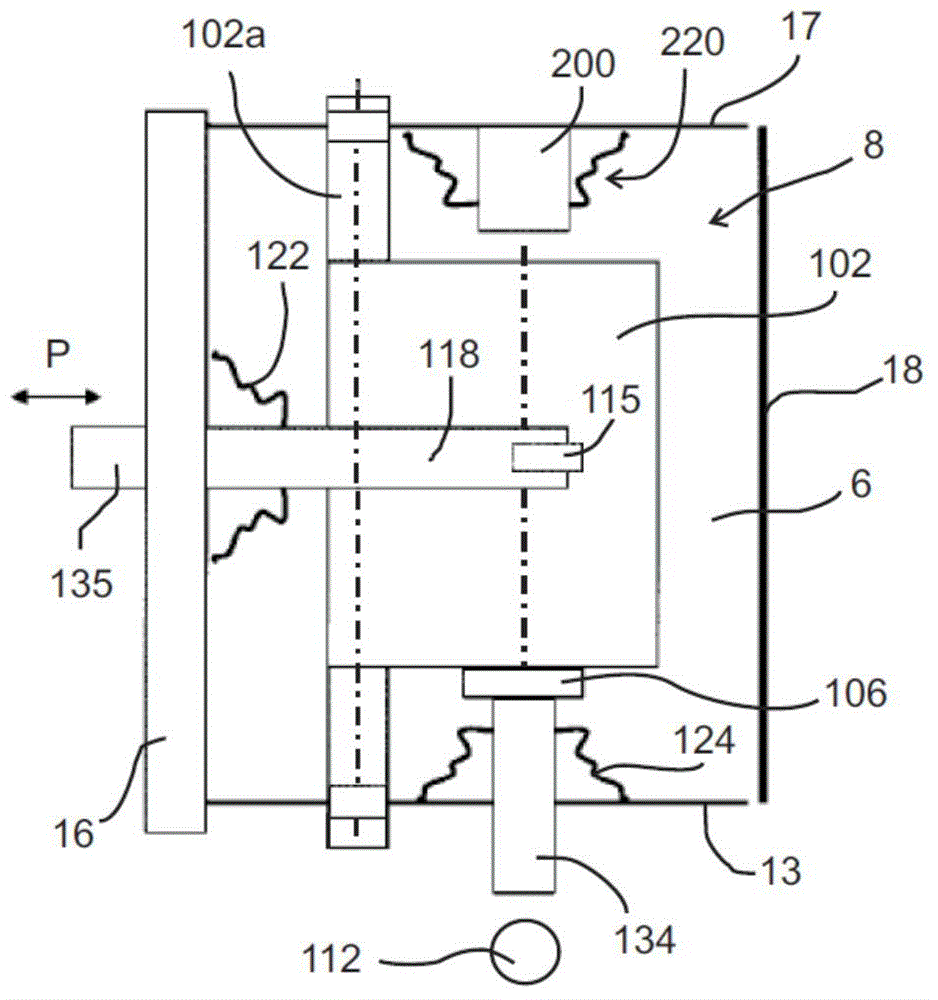

Image

Examples

Embodiment Construction

[0146] Figure 1 is a schematic view of a plant for producing plastic containers according to the prior art. The plant 50 has a heating device 30 in which the plastic parisons 10 are heated. In this case, the plastic parisons 10 are guided through the heating device 30 by means of a conveying device 34 , for example an endless chain in this case, and are heated by heating elements 31 in the process. This heating device 30 adjoins a transfer unit 36 which transfers the parisons 10 to a sterilization device 32 . In this case, the sterilization device 32 also has a transport wheel 37 , and the sterilization elements can be arranged on this transport wheel 37 or can even be fixed. In this area, germs can be sterilized, for example by hydrogen peroxide or even, as mentioned above, by electromagnetic radiation. Specifically, internal sterilization of the parisons is carried out in this area. In the case of electromagnetic radiation, the radiation fingers advantageously protrude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com