Dual-disk power crop root cutting and breaking anti-blocking device of no-tillage planter

A double-disc, stubble-breaking technology, applied to planting methods, agricultural machinery and tools, shovels, etc., can solve the problems of no support, potential safety hazards of planters, and inability to effectively prevent straw from entanglement in the soil, so as to reduce the amount of soil disturbance, Effect of preventing grass clogging and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

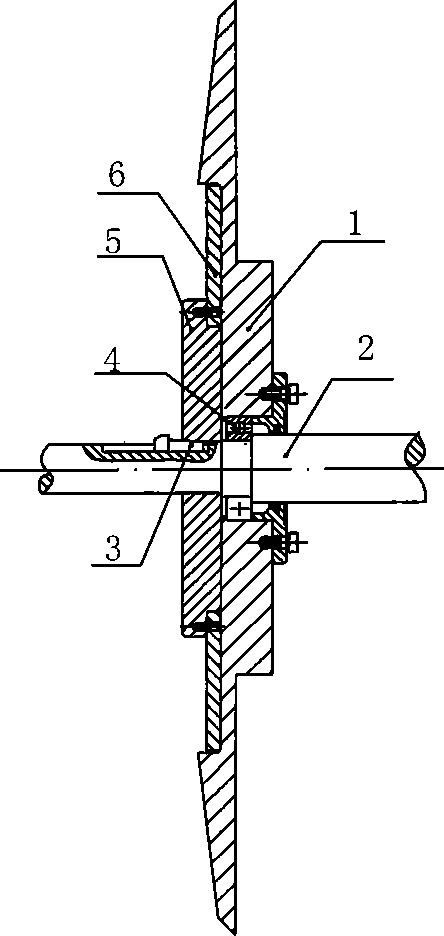

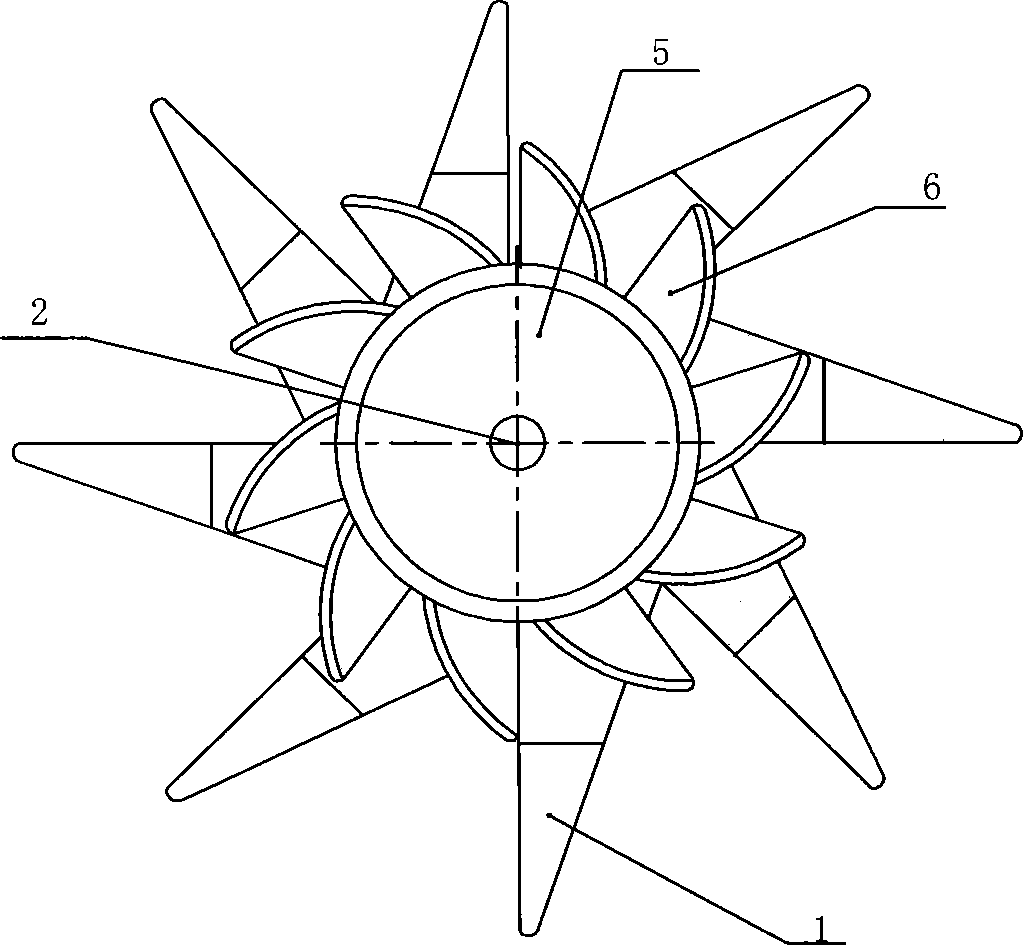

[0008] The specific structure of the present invention is given by the following examples. As shown in the figure, the active disc cutter is composed of a cutter head 5 and several blades 6, and the cutter shaft 2 drives the active disc cutter to rotate in the opposite direction to the forward direction of the machine through the wedge key 3. The passive disc cutter 1 is installed on the cutter shaft 2 through the rolling bearing 4, and the power of the cutter shaft 2 does not drive the passive disc cutter 1 to rotate, and the surface of the passive disc cutter and the active disc cutter are close together. During work, this device is installed on the front of the ditch opener of the no-tillage planter, and the passive disc cutter 1 has a depth of about 10cm in the soil under the gravity of the machine. As the machine advances and rotates in the same direction, the function of breaking soil and stubble is realized. The cutter shaft 2 is driven to rotate by the power of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com