Output filter circuit suitable for large current output electrochemical industrial power supply

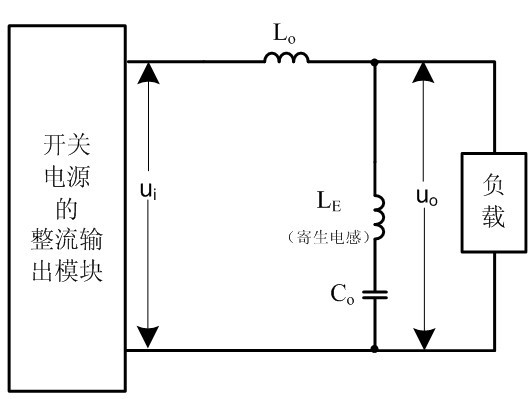

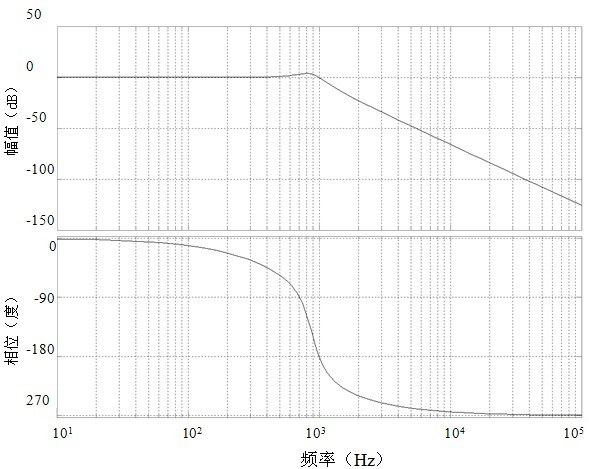

An output filtering and electrochemical technology, which is applied in the field of output filtering, can solve the problems of obvious negative influence, increase of parasitic inductance voltage fluctuation, difficulty in obtaining filtering effect, etc., and achieve the effect of eliminating parasitic and realizing zero ripple output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the implementation and protection scope of the present invention are not limited thereto.

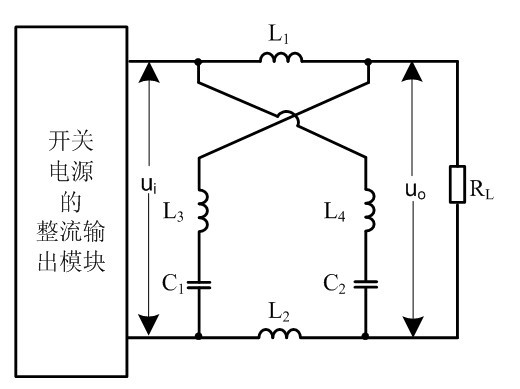

[0016] Such as figure 2 As shown, an output filter circuit suitable for large-current output electrochemical industrial power supplies in this embodiment includes a first inductor L 1 , the second inductance L 2 , the third inductance L 3 , the fourth inductance L 4 , the first capacitance C 1 and a second capacitor C 2 ; An output end of the rectification output module of the power supply and the first inductance L 1 One end of the fourth inductance L 4 One end of the inductance is connected; the first inductance L 1 The other end of the third inductor L 3 One end of the load and one end of the load are connected; the fourth inductance L 4 The other end of the second capacitor C 2 One end of the connection, the second cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com