Large-scale upper oil tank hydraulic power unit

A hydraulic pump station, top-mounted technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of low installation center of gravity, large vibration amplitude and noise of oil pump and motor, and achieve The effects of reducing load power, occupying less space, and less vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

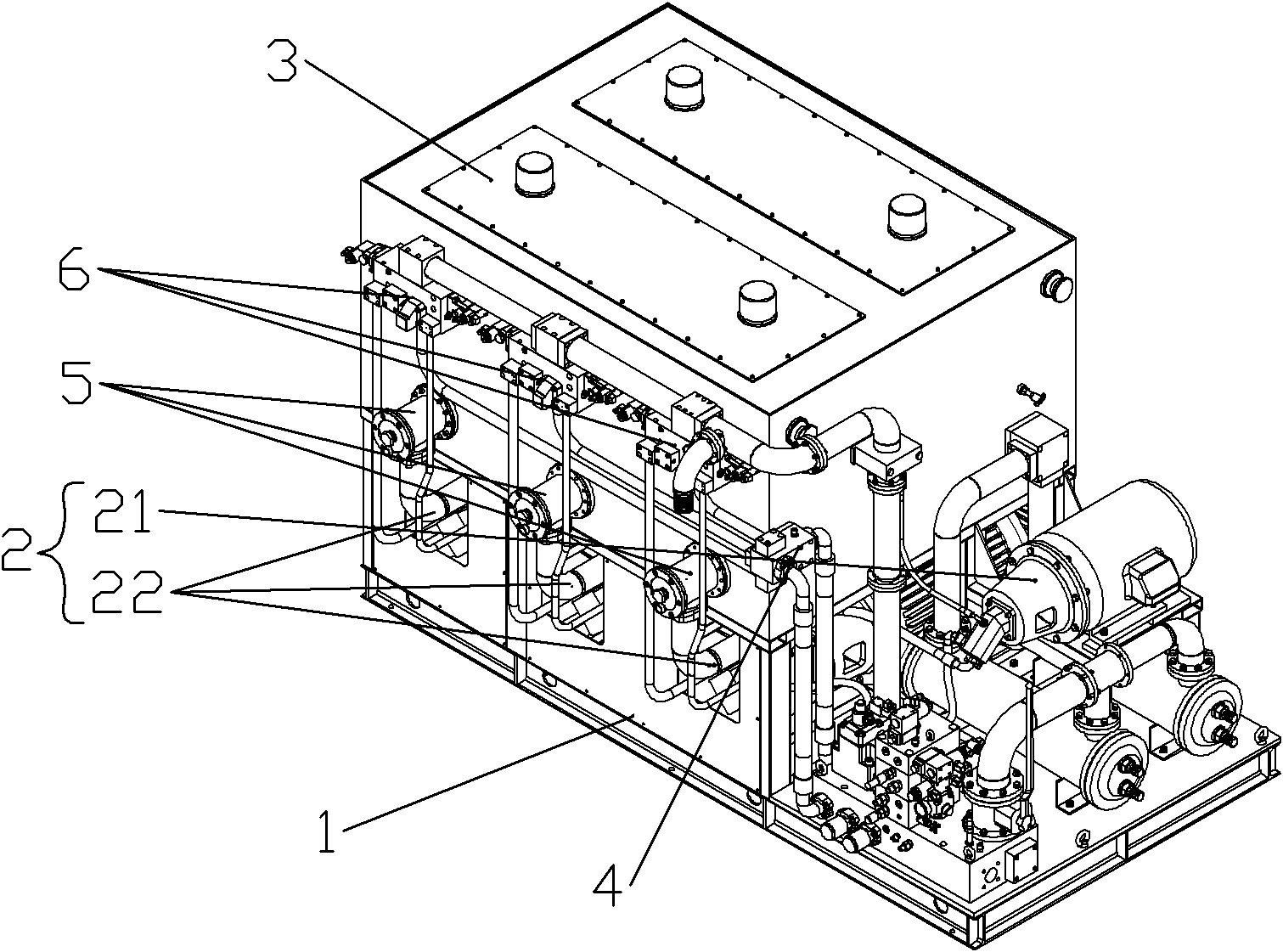

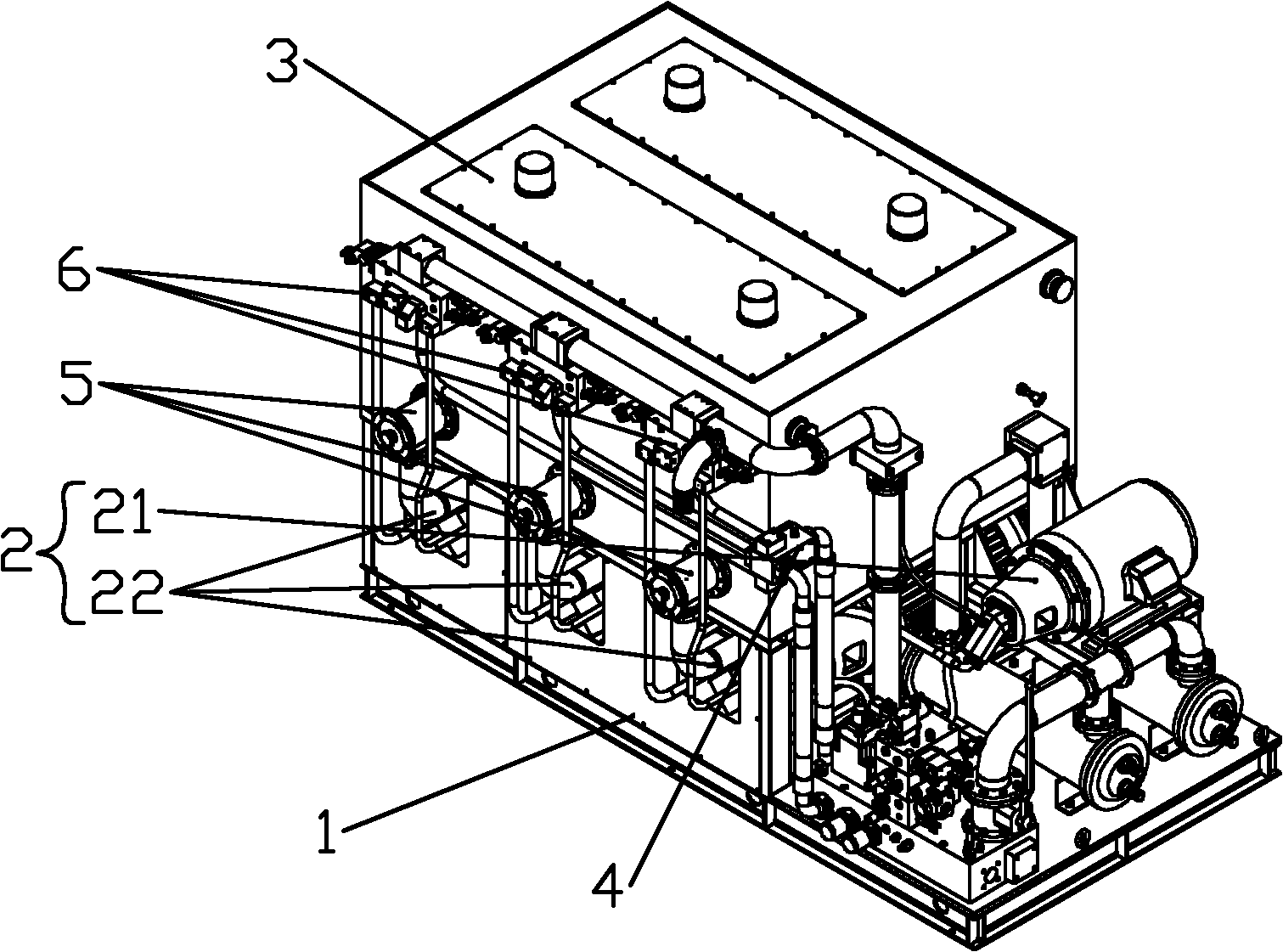

[0014] Such as figure 1 As shown, the large top-mounted oil tank hydraulic pump station described in the present invention is applied to the inner cavity metal extrusion molding machine to provide large flow and adjustable pressure oil for the inner cavity metal extrusion molding machine and provide hydraulic power for each actuator.

[0015] Specifically, the large-scale top-mounted oil tank hydraulic pump station described in the present invention includes a frame 1, an oil pump motor assembly 2 and an oil tank 3. The oil pump motor assembly 2 is installed on the installation platform of the frame 1, and the oil tank 3 passes through The support assembly of the frame 1 is installed above the oil pump motor assembly 2 .

[0016] More specifically, the above-mentioned oil pump motor assembly 2 includes a high-pressure oil pump motor assembly 21 and at least one set of medium-pressure oil pump motor assemblies 22 installed side by side. In an embodiment, the above-mentioned oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com