Double-roller tower type oil-pumping unit device

A technology of drum tower and pumping unit, which is applied in the direction of mining fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of easy slipping of belt, no anti-skid measures of drum, poor stability, etc., and achieve good stability and convenient use , the effect of improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

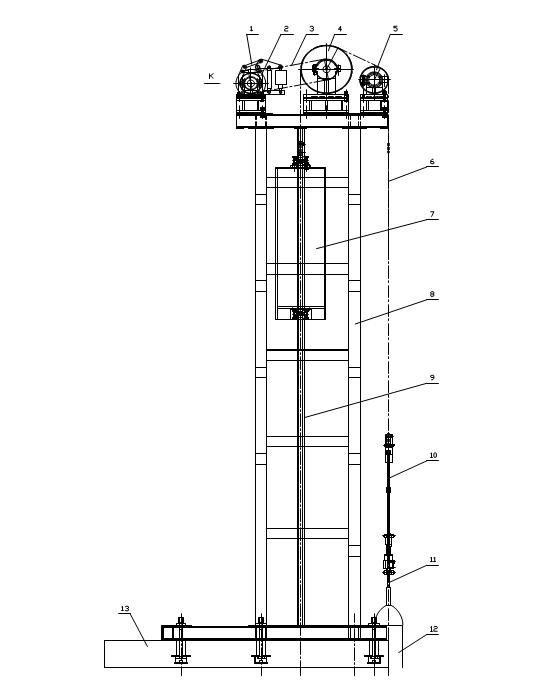

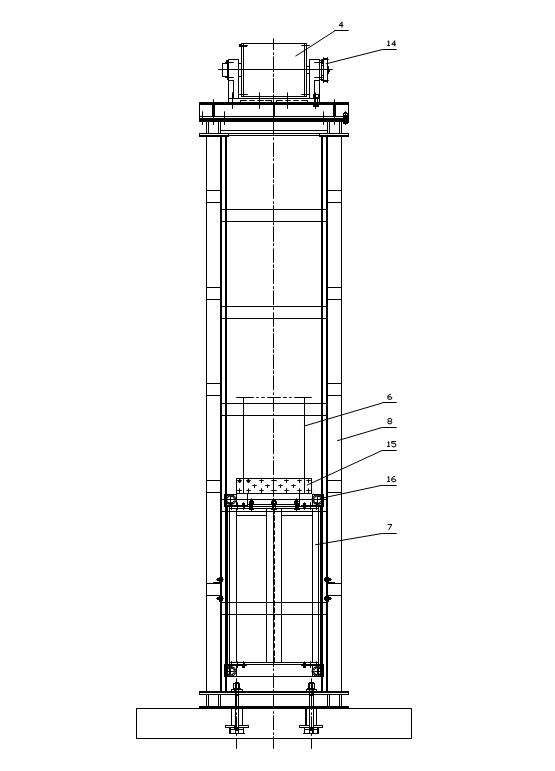

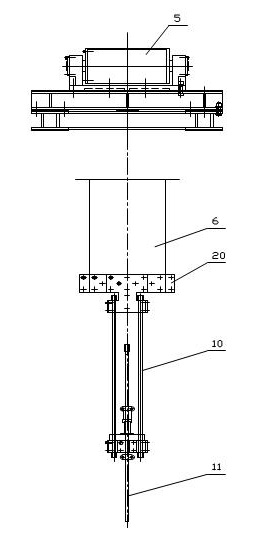

[0020] Accompanying drawing is the embodiment of the patent of the present invention.

[0021] Below in conjunction with accompanying drawing, the content of the invention is further described:

[0022] Such as figure 1 , 2 , 3, a double-drum tower pumping unit, the device consists of a brake, a three-phase asynchronous motor, a synchronous belt, a drum reducer, a driven drum, an open belt, a counterweight box, a frame, a guide rail, a pumping Oil rod suspension assembly, oil sucker rod, oil pump, concrete foundation, driven synchronous pulley, a belt clip, guide wheel assembly, coupling assembly, driving synchronous pulley, pulley shaft, and another belt clip. The drum type speed reducer 4 drives the driven drum 5 to rotate through the open belt 6, one end of the open belt 6 is connected with the counterweight box 7 through a belt clip 15, and the other end of the open belt 6 is connected with the sucker rod suspension assembly 10 One end is connected together, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com