Anti-icing coating for insulator

A technology for insulators and coatings, applied in the field of materials, can solve the problems of safe and reliable operation loss of power systems, affecting the safe and effective operation of power grids, and icing of transmission lines, so as to ensure safe and reliable power transmission, increase pollution flashover voltage, and reduce power loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of anti-icing coating for insulators

[0024] An anti-icing paint for insulators, the paint is composed of a high resistivity paint and a low resistivity paint, the high resistivity paint includes silicone rubber, and a semiconductor filler with a mass percentage of 0.1% is added to the silicone rubber Carbon black, high resistivity coatings with resistivity in the range of 10 14 More than Ω·cm; the low-resistivity coating includes silicone rubber, and in the silicone rubber, a semiconductor filler carbon black of 15% by mass percentage is also added, and the low-resistivity coating resistivity is at 10 5 ~10 9 within the range of Ω·cm.

[0025] The type of the carbon black is a special conductive carbon black with a chain-like conductive structure. The specific specifications of special conductive carbon black are shown in the table below.

[0026] BET specific surface area (m 2 / g)

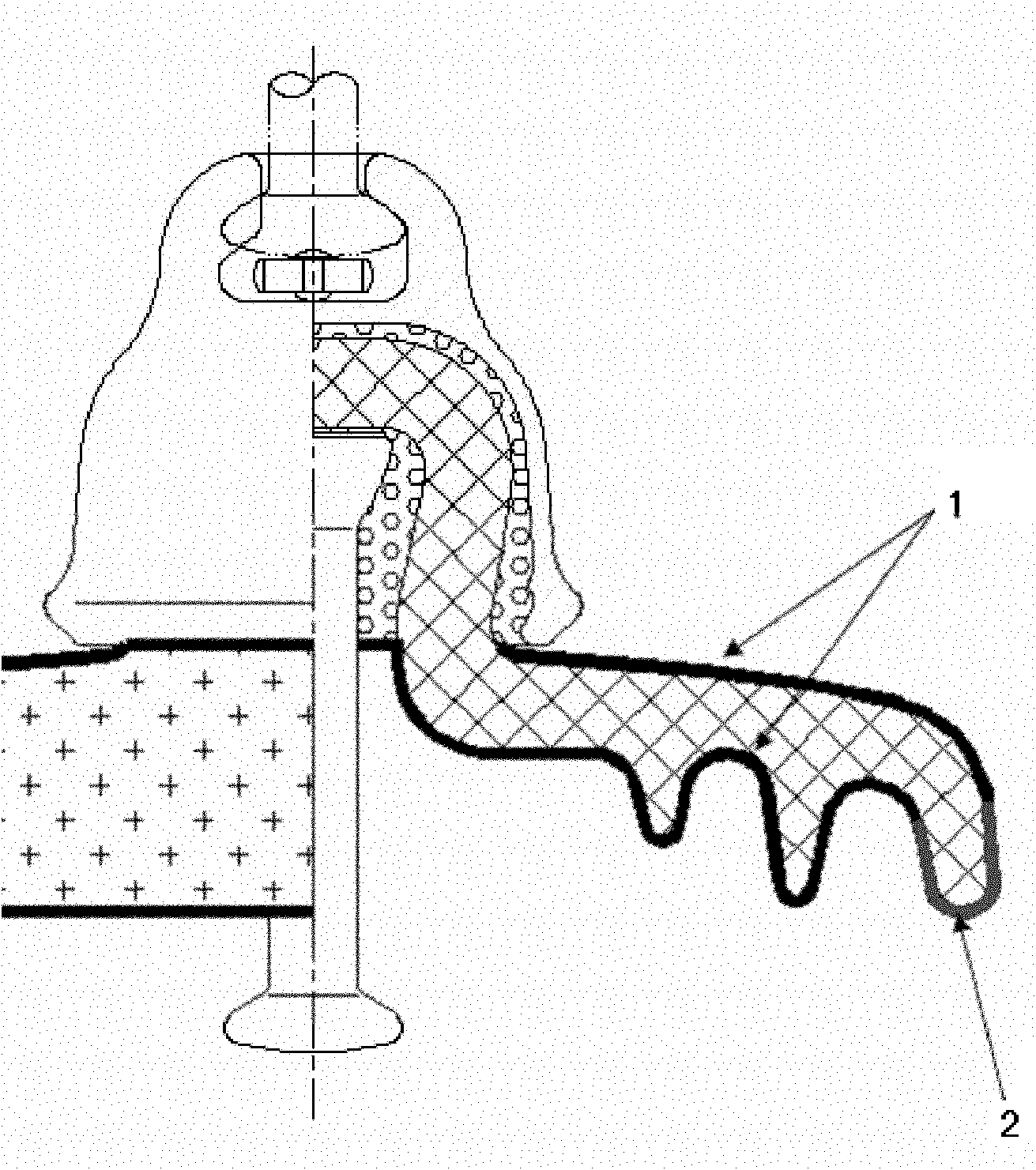

[0027] see figure 1 , is a schematic diagram of ...

Embodiment 2 application Embodiment 1

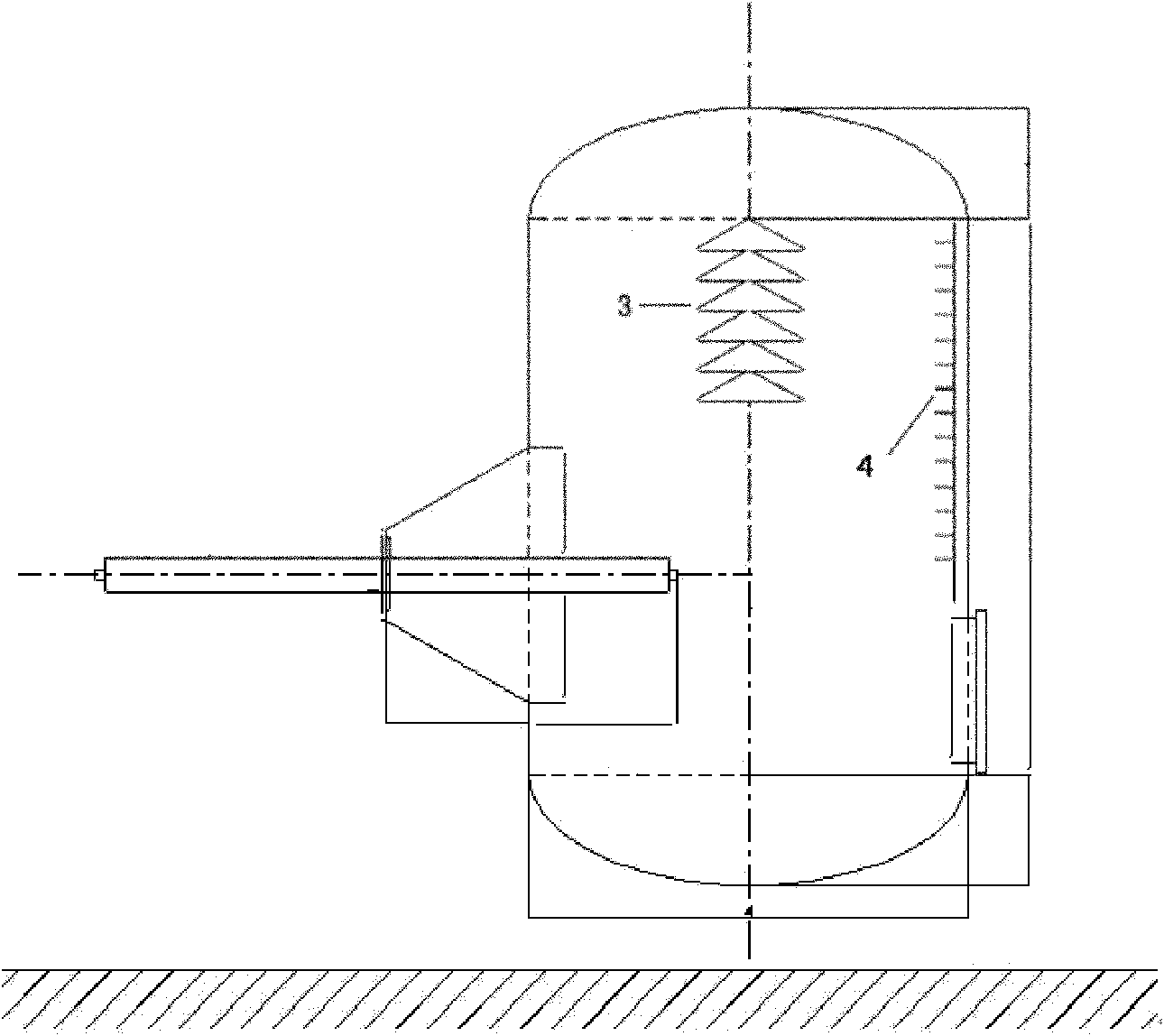

[0028] Example 2 The effect of applying the 110kV insulator string anti-icing coating of Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com