Tire self-inflating system

A self-inflating, tire technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problems of not being able to guarantee tire pressure at all times, increasing tire slippage and being cut, unable to realize automatic inflation and deflation, etc. Easy to install and maintain, prevent puncture, prolong tire life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

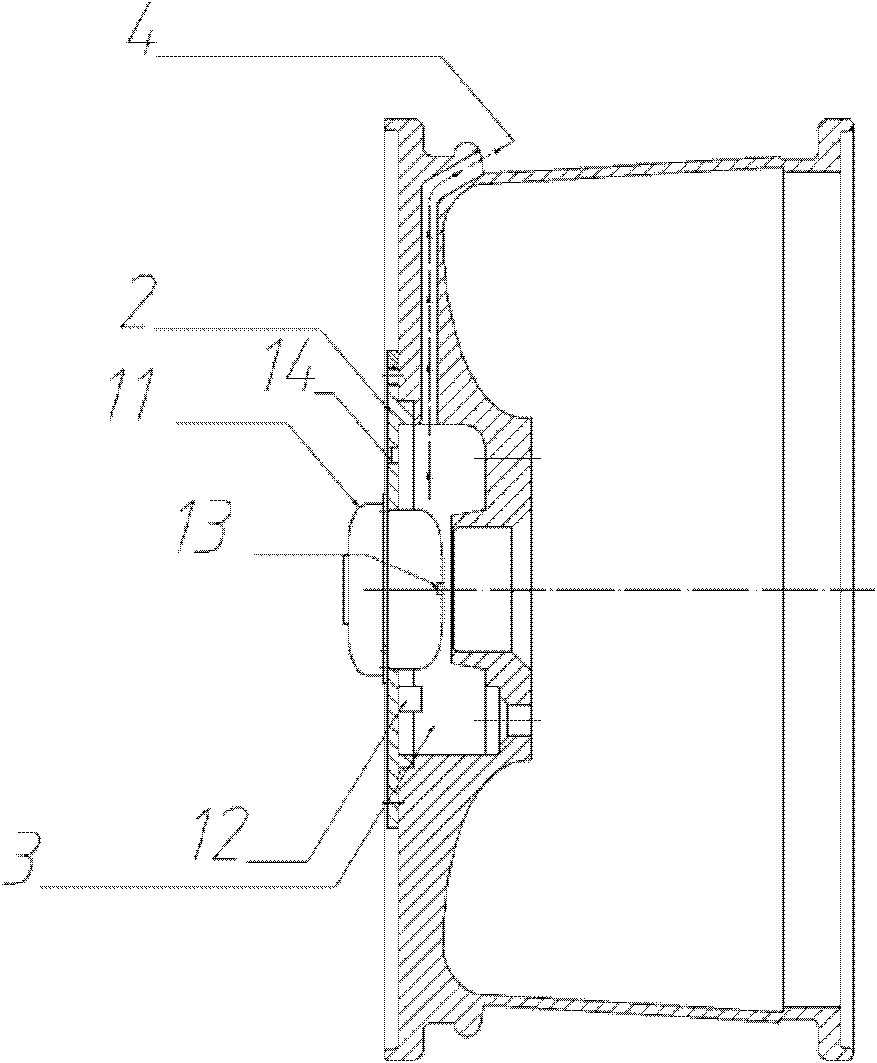

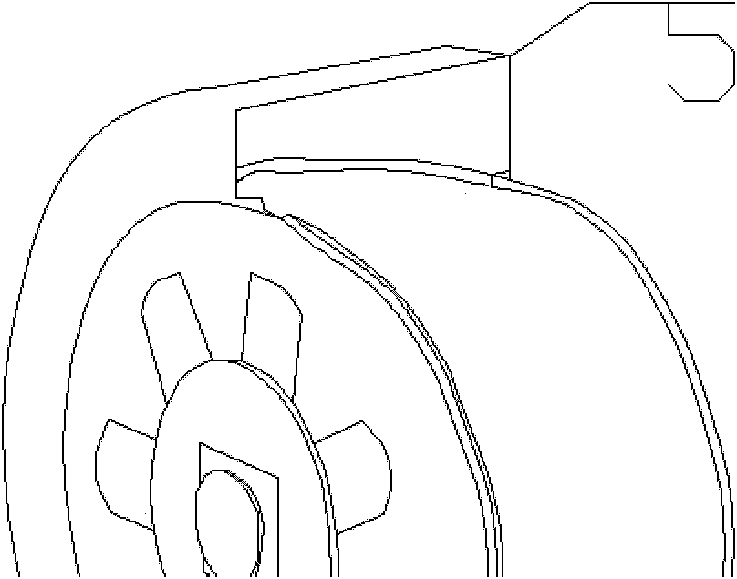

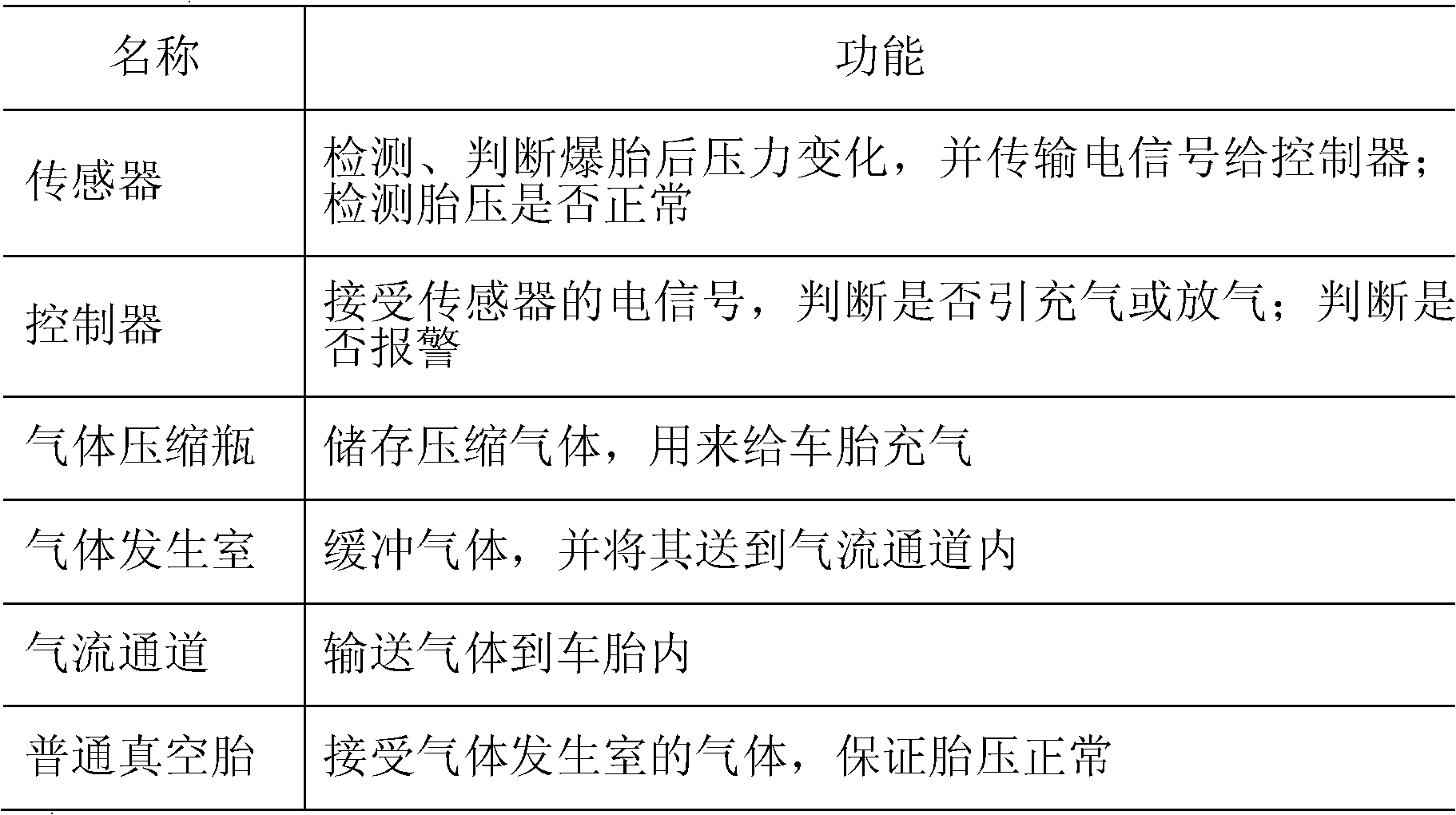

[0017] figure 1 and figure 2 It is the structure of the tire self-inflating system of the present invention. As shown in the figure, it includes: gas compression bottle 11, control sensing device 12, inflation valve 13, deflation valve 14 (, cover 2, gas generation chamber 3, air flow channel 4, common vacuum tire 5. The present invention controls The sensor of the sensing device 12 detects the tire pressure, and sends an electric signal to the controller controlling the sensing device 12. The controller is provided with a comparison circuit. If the tire pressure is lower than the normal threshold, the inflation valve 13 of the gas compression bottle 11 is opened, Inflate the tire 5, and when the air pressure reaches the specified value, the controller sends an instruction to close the inflation valve 13. When the air pressure in the tire 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com