Mould processing cost management system and method

A cost management and mold processing technology, applied in the field of management system, can solve the problems of lag, time delay to half a year or even more than one year, unfavorable operation and management, etc., to achieve the effect of improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

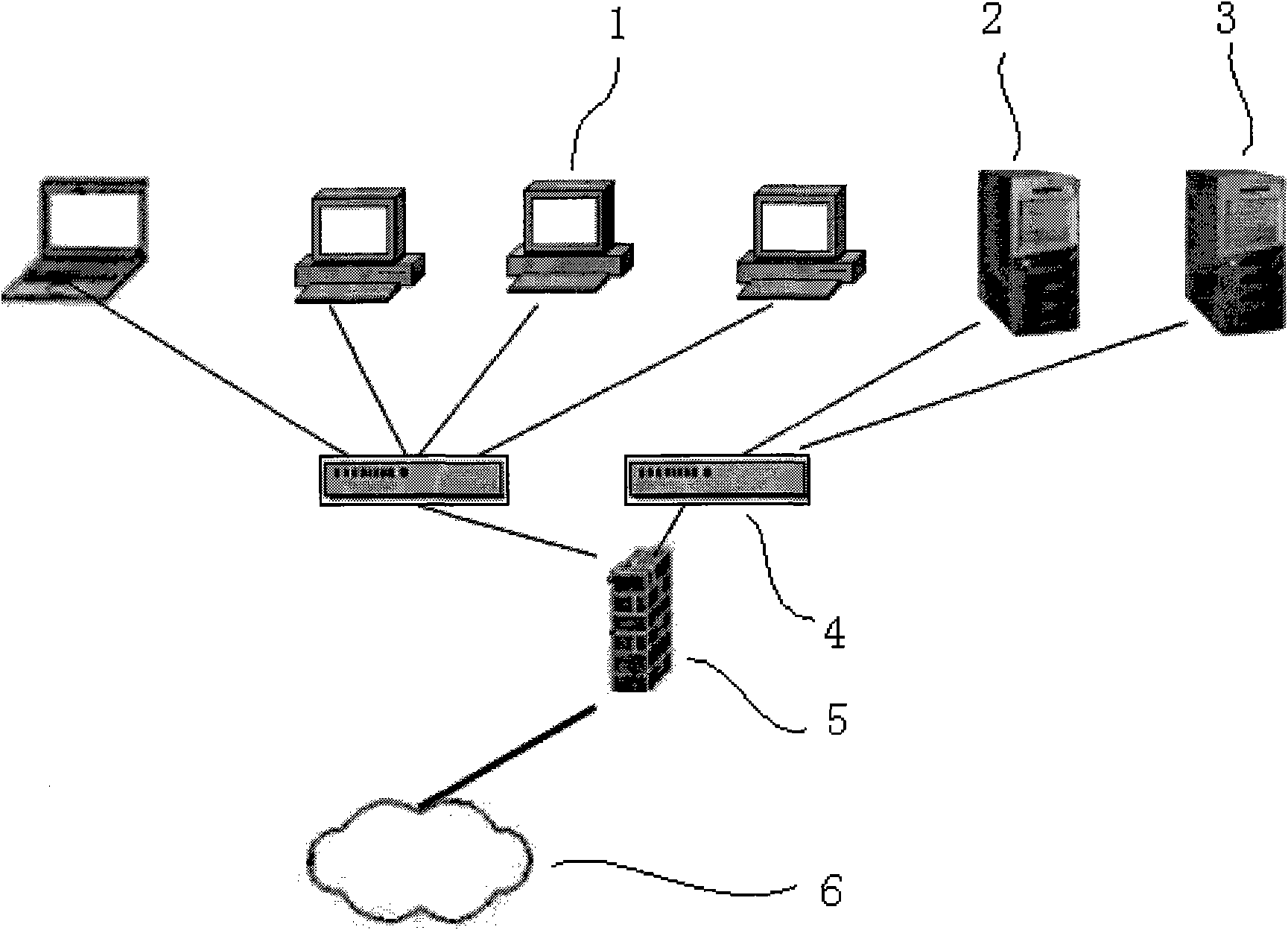

[0047]A mold processing cost management system, the system framework is composed of a client, a server connected to the client through a network (see figure 1 ), described client includes four client computers 1, client software installed on the client computer, and described server includes database server 3 and the uploading and downloading that can realize file, to realize the FTP server of information sharing 2; a firewall 5 is arranged between the client and the server, the four client computers 1 are connected to one end of the firewall 5 through the switch 4, and the other end of the firewall 5 is connected to the database server 3 and the database server 5 through the switch 4 FTP server 2 is connected, and another end of firewall 5 is connected with Internet 6 by optical fiber.

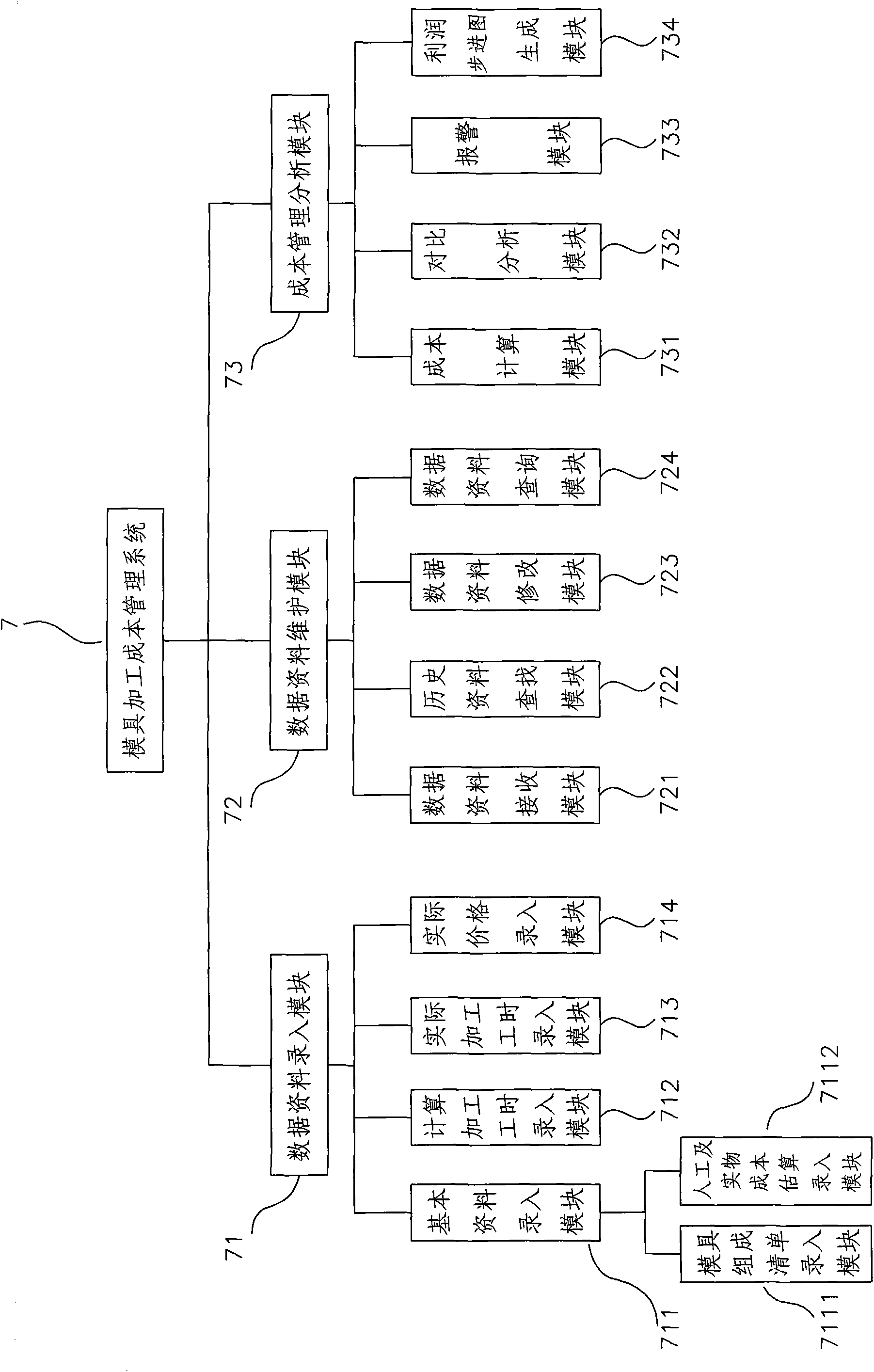

[0048] In this mold processing cost management system, the client software includes a data entry module 71 for entering data, and the database server 3 includes a data maintenance module 72, ...

Embodiment 2

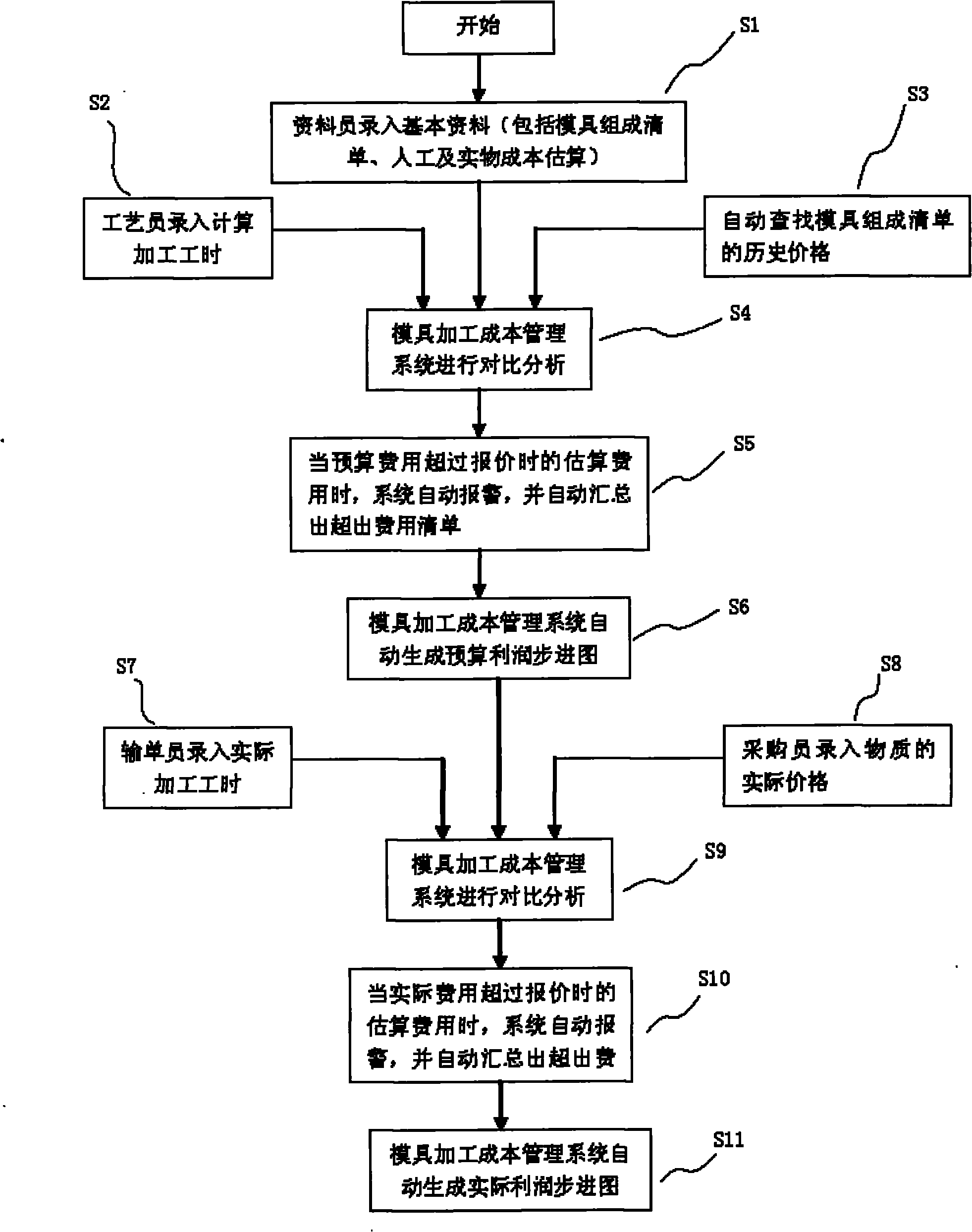

[0056] A mold processing cost management method, which is a method for monitoring and managing the mold processing cost by using the mold processing cost management system described in Embodiment 1, the method includes the following main steps (see image 3 block diagram of the process):

[0057] S1. Enter basic information:

[0058] The data clerk enters the basic data including the mold composition list and the labor and physical cost estimates made during the quotation;

[0059] S2. Input and calculate processing hours:

[0060] After the mold design is completed, the craftsman formulates the processing technology and calculates the processing hours according to the basic information, and enters the calculated processing hours into the mold processing cost management system. The labor cost budget is obtained by multiplying the unit price of the proposed processing procedure and the calculated processing hours ;

[0061] S3. Automatically find historical prices:

[0062]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com