Milling force modeling method for titanium alloy TC18 milling process

A TC18, modeling method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the non-zero milling force with equal phase width of the tool cannot be effectively simulated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

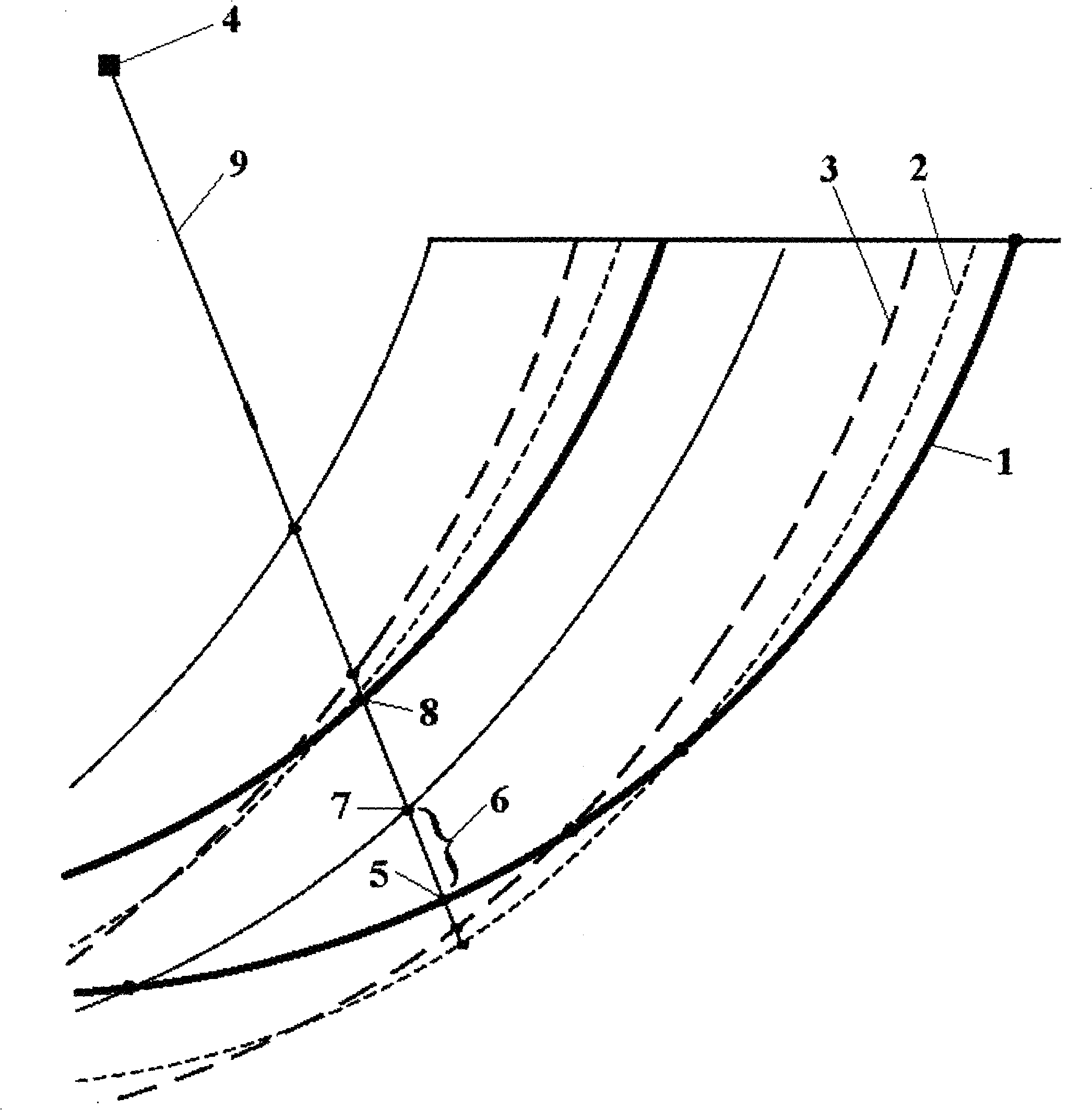

Method used

Image

Examples

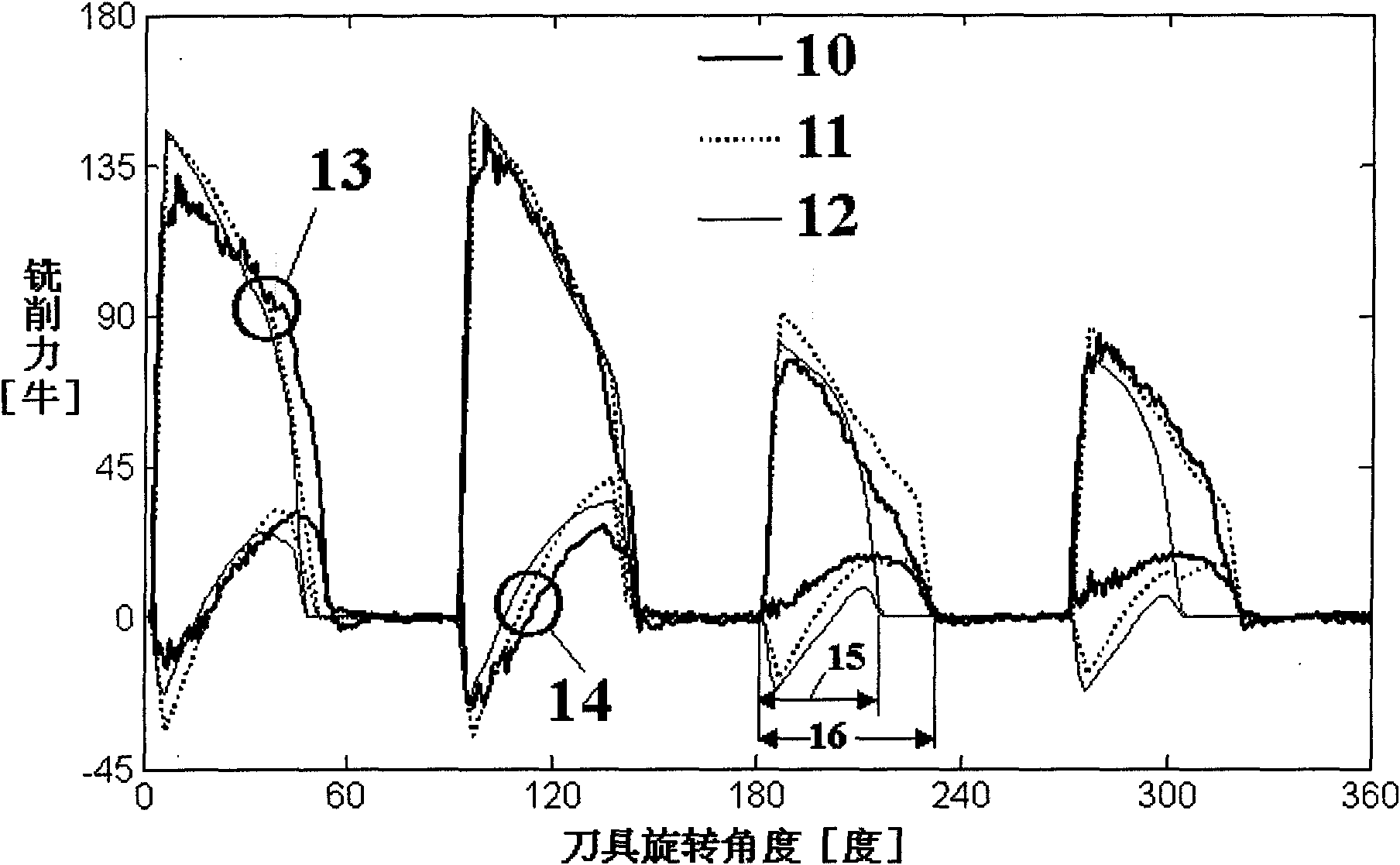

Embodiment 1

[0077] (1) Select the parameters of the end mill: the tool radius R is 6mm, the helix angle β is 37 degrees, the bottom edge inclination angle η is 3 degrees, and the number of tool teeth is N f is 4; milling method: down milling. Set the cutting parameters: the tool spindle speed is 600RPM, the single tooth feed rate is 0.0625mm / tooth, the axial cutting depth Rz is equal to 0.4mm, and the radial cutting depth Rr is equal to 2mm.

[0078] (2) Divide the milling cutter into 400 equal-height beam segments in the axial direction, and calculate the tangential milling force F acting on the j-th side edge unit on the i-th tooth at time t by the following formula T,F,i,j (t) and radial milling force F R,F,i,j (t):

[0079] f T,F,i,j (t)=K T,F,i,j h F,i,j (t)w z

[0080] f R,F,i,j (t)=K R,F,j,j h F,i,j (t)w z

[0081] In the formula, K T,F,i,j is the tangential milling force coefficient corresponding to the jth side edge unit on the ith tooth, K R,F,i,j is the radial mil...

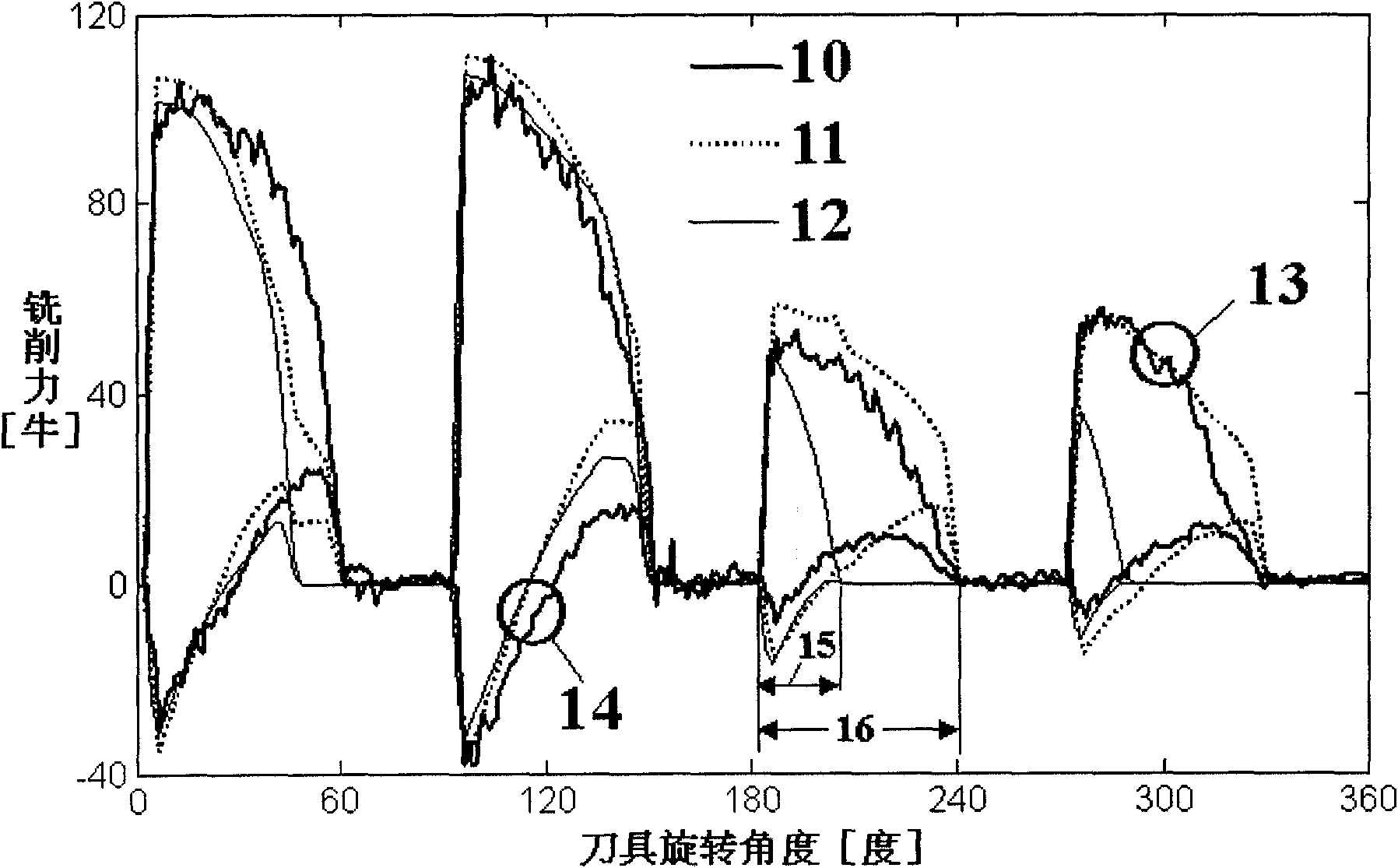

Embodiment 2

[0130] (1) Select the parameters of the end mill: the tool radius R is 6mm, the helix angle β is 37 degrees, the bottom edge inclination angle η is 3 degrees, and the number of tool teeth is N f is 4; milling method: down milling. Set the cutting parameters: the tool spindle speed is 800RPM, the single tooth feed rate is 0.03125mm / tooth, the axial cutting depth Rz is equal to 0.4mm, and the radial cutting depth Rr is equal to 2.5mm.

[0131] (2) Divide the milling cutter into 400 equal-height beam segments in the axial direction, and calculate the tangential milling force F acting on the j-th side edge unit on the i-th tooth at time t by the following formula T,F,i,j (t) and radial milling force F R,F,i,j (t):

[0132] f T,F,i,j (t)=K T,F,i,j h F,i,j (t)w z

[0133] f R,F,i,j (t)=K R,F,i,j h F,i,j (t)w z

[0134] In the formula, K T,F,i,j is the tangential milling force coefficient corresponding to the jth side edge unit on the ith tooth, K R,F,i,j is the radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com