Rolling bearing

A technology for rolling bearings and bearings, which is applied in the direction of rolling contact bearings, bearings, and rotating bearings, etc., and can solve problems such as out-of-tolerance roundness, ellipticity, and verticality of the outer ring of rolling bearings, poor sealing and dustproof effects, and bearing degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

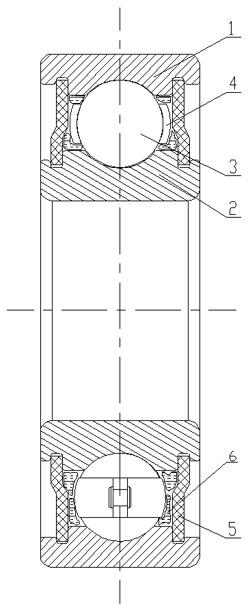

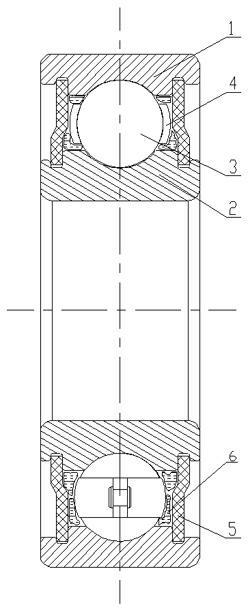

[0012] The rolling bearing of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the rolling bearing of the present invention includes: an outer ring 1, an inner ring 2, a rolling element 3, and a cage 4; the rolling element 3 is located between the inner ring 2 and the raceway of the outer ring 1; The rolling elements 3 are evenly separated; the sealing device 5 is arranged in the sealing groove of the bearing ring, and the sealing device 5 is arranged on the outside of the cage 4. The minimum radial sealing gap and the minimum axial sealing gap are at least 0.001mm.

[0014] When installing, take the bearing outer ring 1, inner ring 2, rolling element 3 and cage 4 that are currently machined and waiting to be assembled, complete the selection and riveting and clean and dry according to the normal bearing assembly process; then, add lubrication to the inside of the rolling bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com