Method for predicting shaft power of industrial extraction condensing steam turbine

A prediction method, steam turbine technology, applied in neural learning methods, mechanical equipment, engine components, etc., can solve problems such as complexity, difficulty in steam turbine estimation, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is further described by specific application examples:

[0039] Such as Figure 4 Shown is the hardware architecture diagram for the implementation of this measurement method. The instrument collects real-time data information from each node of the industrial process object. The database contains historical data information. The host computer processes real-time data information and historical data information through the data bus.

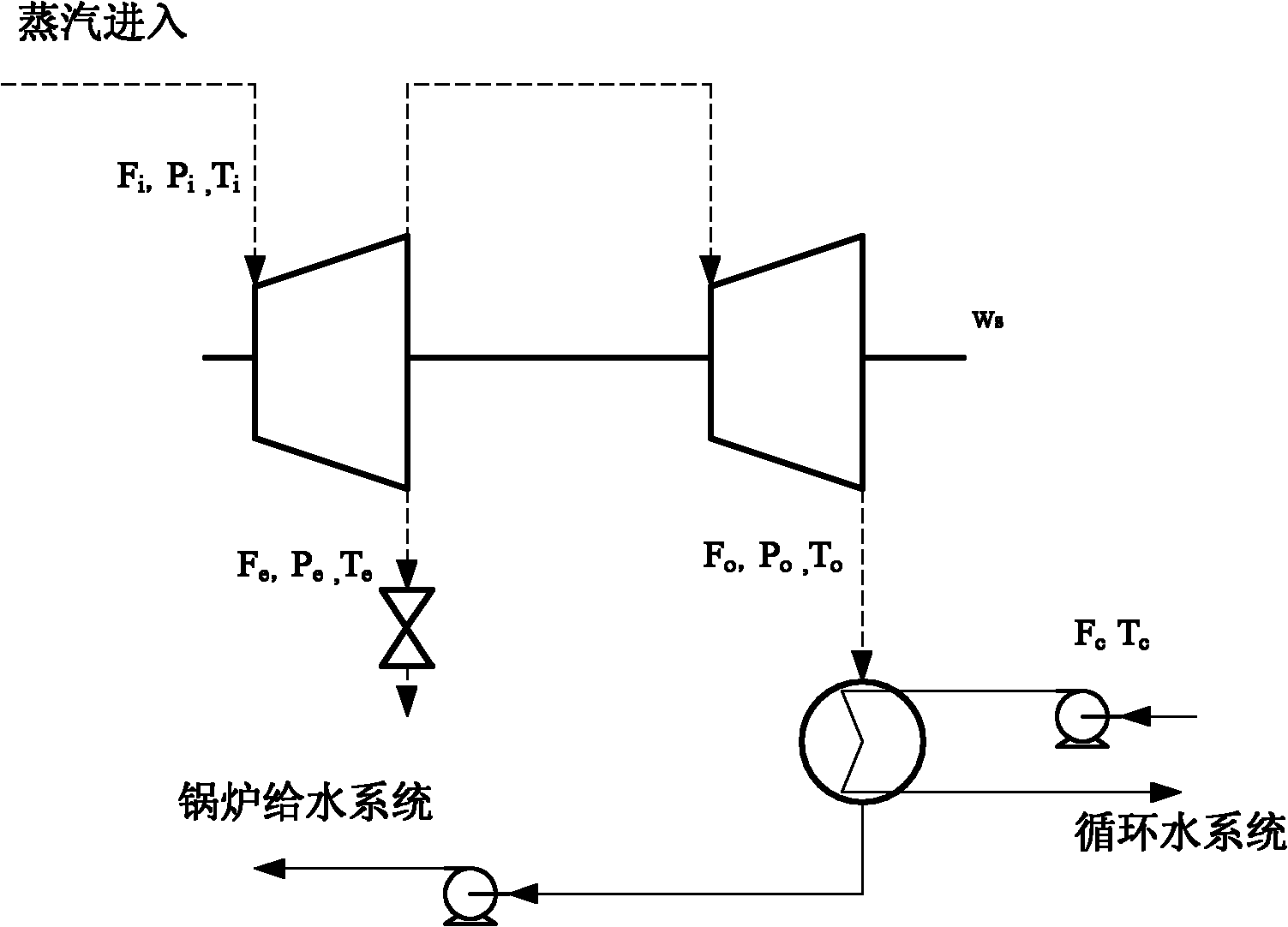

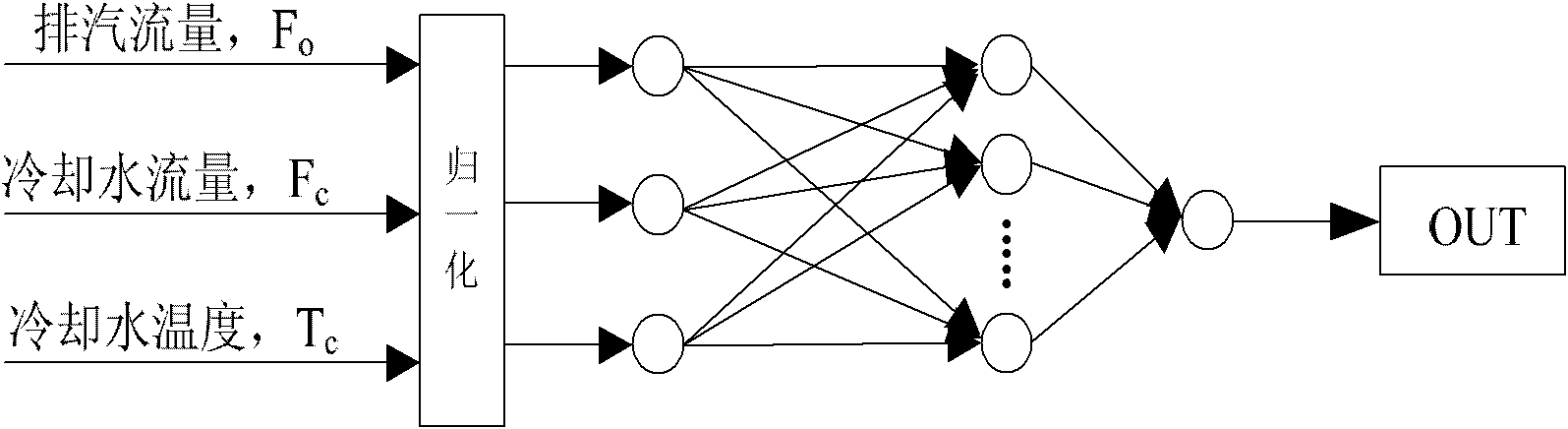

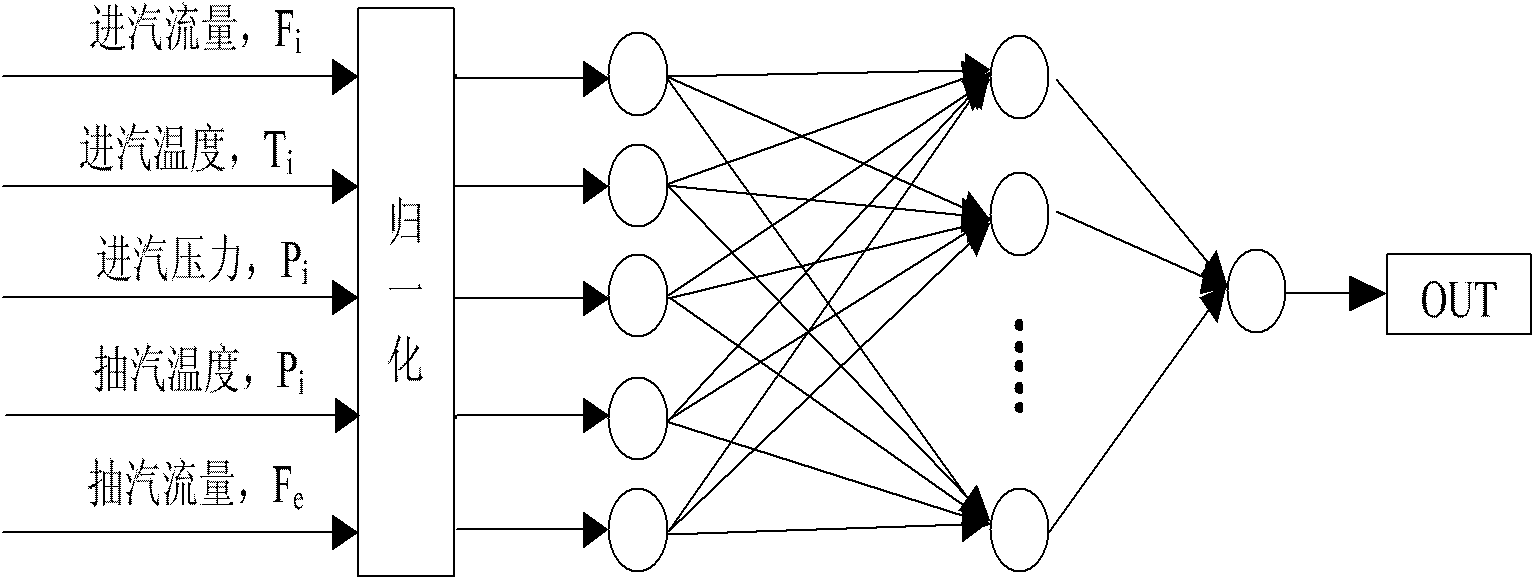

[0040] The method of the present invention first collects by measuring instrument during the operation of the extraction condensing turbine, the main steam inlet flow, pressure and temperature; the flow, pressure and temperature of the extraction steam; the flow and temperature of the cooling water of the condenser, and the steam turbine entering the condenser Exhaust flow, and its corresponding shaft power (W s , kw) and the pressure inside the condenser (P o , MPa). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com