Polyolefin semiconductive composite for organosilane crosslinked overhead cables with rated voltage of less than or equal to 20KV

A silane cross-linking, overhead cable technology, applied in the direction of insulated cables, cables, conductors, etc., can solve the problem of not realizing industrialized production, and achieve the effects of improving product quality, reducing production costs, and simplifying production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

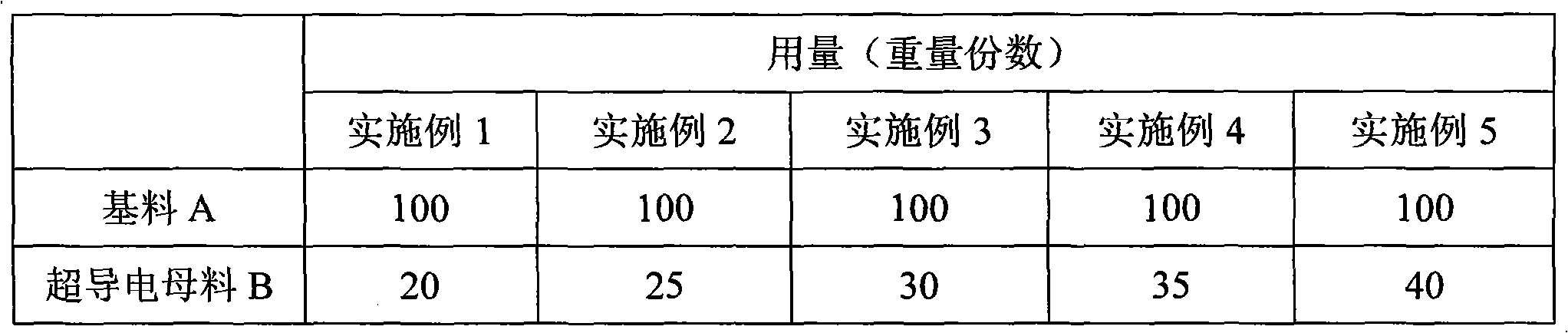

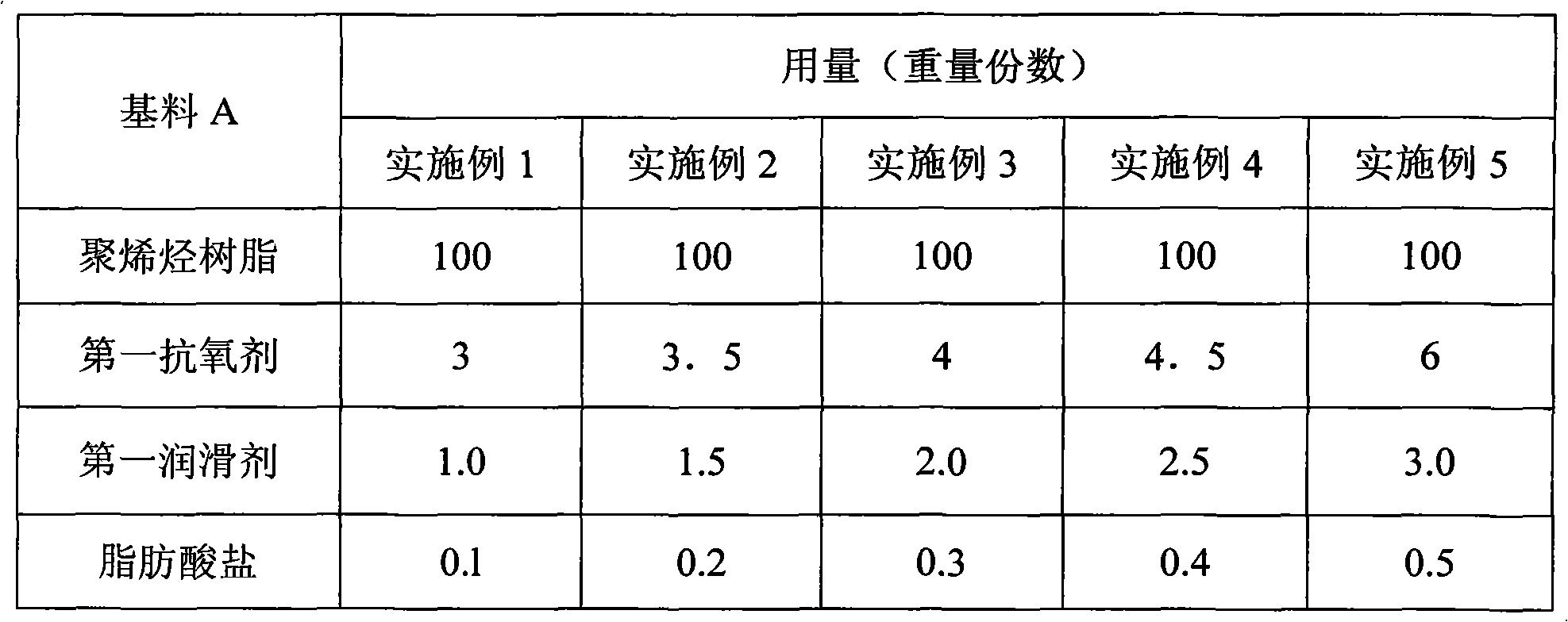

Method used

Image

Examples

Embodiment 5

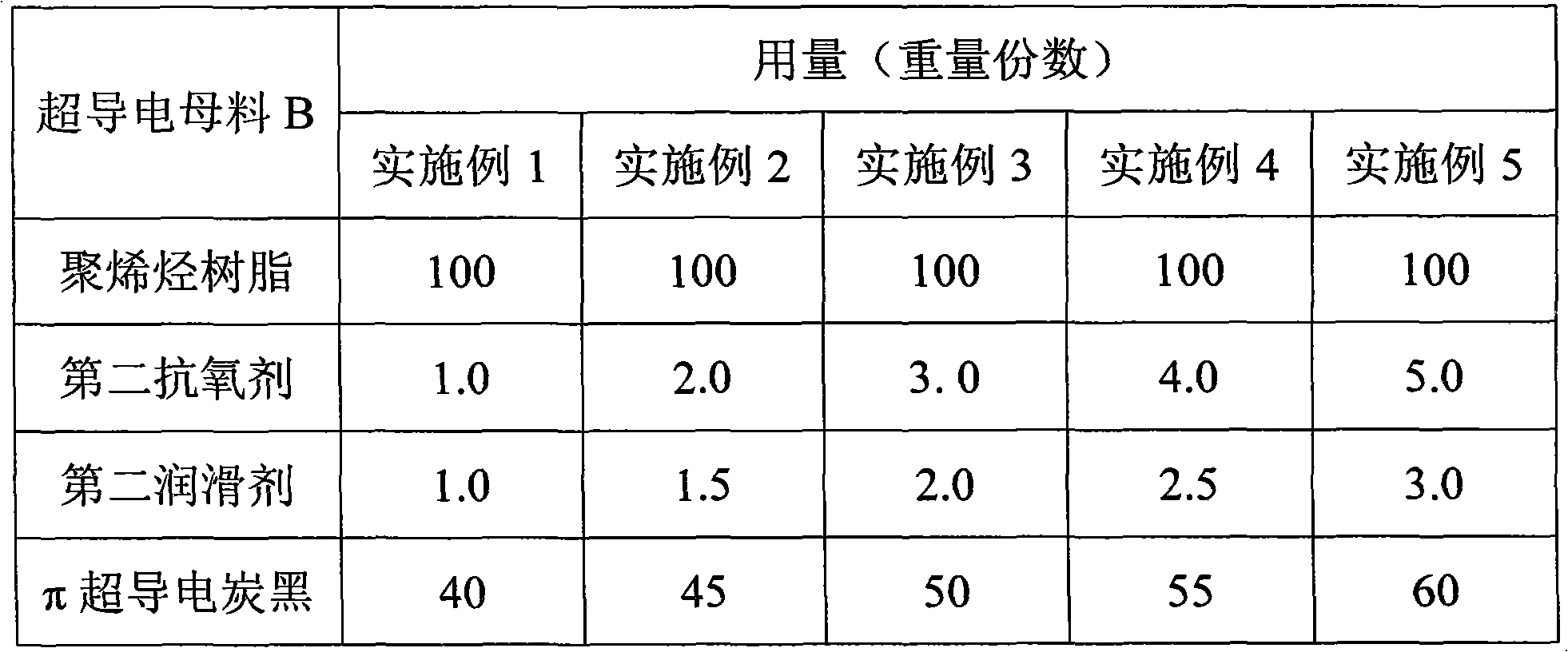

[0021] In Example 5, LDPE:LLDPE=75:25.

[0022] In an embodiment, the second antioxidant in the superconducting masterbatch B containing π bonds is selected from tetrakis[β-(3,5-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, tetrakis A mixture of [β-(3,5-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester and three (2,4-di-tert-butylphenyl) phosphite, the ratio of the two is (1 ~2): 1, preferably IRGANOX B225, IRGANOX B215.

[0023] The second lubricant in the superconducting masterbatch B containing π bonds is dimethyl silicone oil or white oil.

[0024] In Examples 1, 2 and 3, the π superconducting carbon black contained in the superconducting masterbatch B containing π bonds is JE6900, and that in Examples 4 and 5 is VXC200.

[0025] The production process of the superconducting masterbatch B containing π bonds is as follows: polyolefin resin, second antioxidant, second lubricant, and superconducting carbon black containing π bonds are mixed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com