Technique for manufacturing high-strength encaustic tiles and extruding device thereof

A production process and extrusion device technology, applied in the field of high-strength color tile production process and its extrusion device, can solve the problems of unsuitable mass production, low degree of automation, high labor intensity of workers, etc., and achieve easy control , The effect of high product strength and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

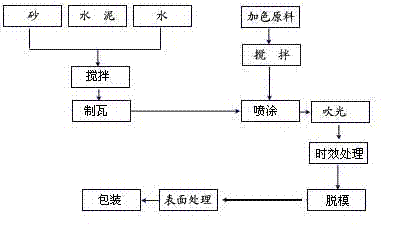

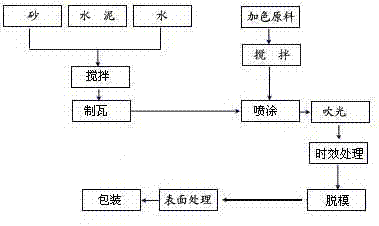

[0020] This embodiment provides a high-strength colored tile manufacturing process, which is characterized in that: the high-strength colored tile manufacturing process is to mix sand, cement, and water in a ratio of 1.12:1:0.38, stir with a mixer, and inject Into the barrel of the tile making machine, through the extrusion device of the tile making machine, extrude the uniformly mixed raw materials with a particle size of 55-125 microns, and extrude them onto the tile mold covered with glass fiber;

[0021] The color-adding propylene raw material is stirred by a small mixer, sprayed onto the surface of the tile on the tile mold, and after 30 minutes, under the gas pressure of 2.3 atmospheres, the surface is blown off;

[0022] Then put it on the tile frame, in an environment with a temperature of 20°C and a humidity of 15%, aging treatment for 6 hours, then mechanical demoulding, and then surface treatment to remove burrs from the corners, and finally packaged.

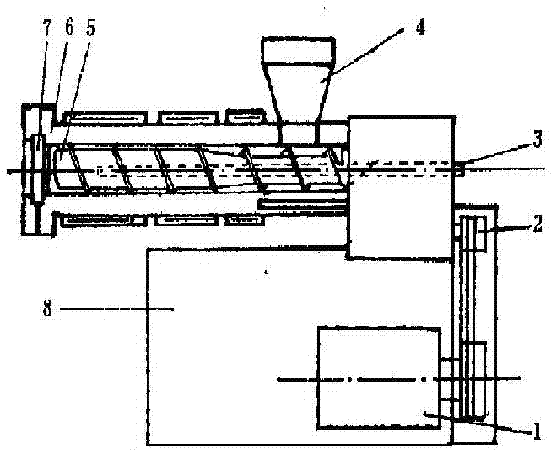

[0023] The e...

Embodiment 2

[0032] This embodiment provides a high-strength colored tile manufacturing process, which is characterized in that: the high-strength colored tile manufacturing process is to mix sand, cement, and water in a ratio of 1.5:1:0.50, stir with a mixer, and inject Into the barrel of the tile making machine, through the extrusion device of the tile making machine, extrude the uniformly mixed raw materials with a particle size of 55-125 microns, and extrude them onto the tile mold covered with glass fiber;

[0033] The color-adding propylene raw material is stirred by a small mixer, sprayed onto the surface of the tile on the tile mold, and after 30 minutes, under the gas pressure of 2.5 atmospheres, the surface is blown off;

[0034] Then put it on the tile rack, in an environment with a temperature of 40°C and a humidity of 25%, aging treatment for 8 hours, then mechanical demoulding, and then surface treatment to remove burrs from the corners, and finally packaged.

[0035] The ext...

Embodiment 3

[0044] This embodiment provides a high-strength colored tile manufacturing process, which is characterized in that: the high-strength colored tile manufacturing process is to mix sand, cement, and water in a ratio of 1.2:1:0.4, stir with a mixer, and inject Into the barrel of the tile making machine, through the extrusion device of the tile making machine, extrude the uniformly mixed raw materials with a particle size of 55-125 microns, and extrude them onto the tile mold covered with glass fiber;

[0045] The color-added propylene raw material is stirred by a small mixer, sprayed onto the surface of the tile on the tile mold, and after 30 minutes, under the gas pressure of 2.4 atmospheres, the surface is blown off;

[0046] Then put it on the tile rack, in an environment with a temperature of 30°C and a humidity of 25%, aging treatment for 8 hours, then mechanical demoulding, and then surface treatment to remove burrs from the corners, and finally packaged.

[0047] The extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com