Polyamide composite nanofiltration membrane

A technology of composite nanofiltration membrane and polyamide, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as low performance, single type of composite nanofiltration membrane, and inability to meet practical application requirements, etc., to achieve The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

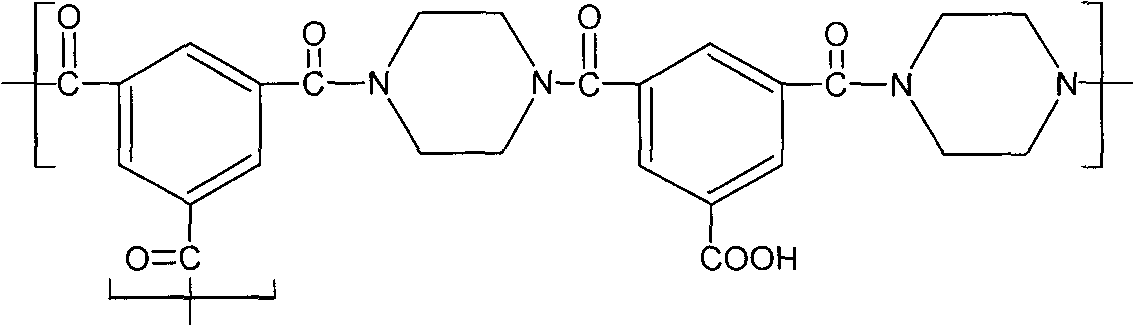

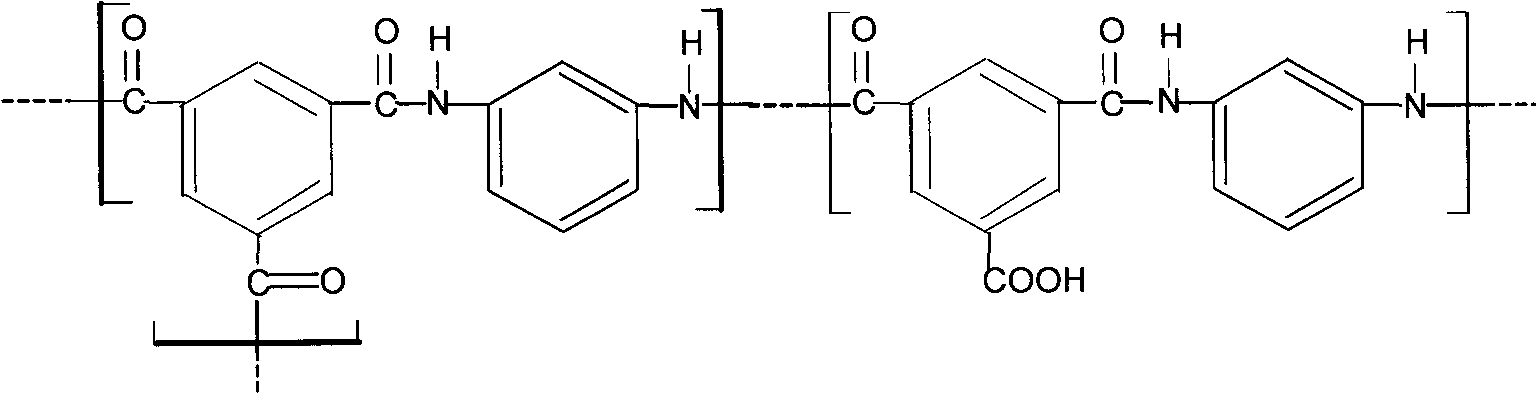

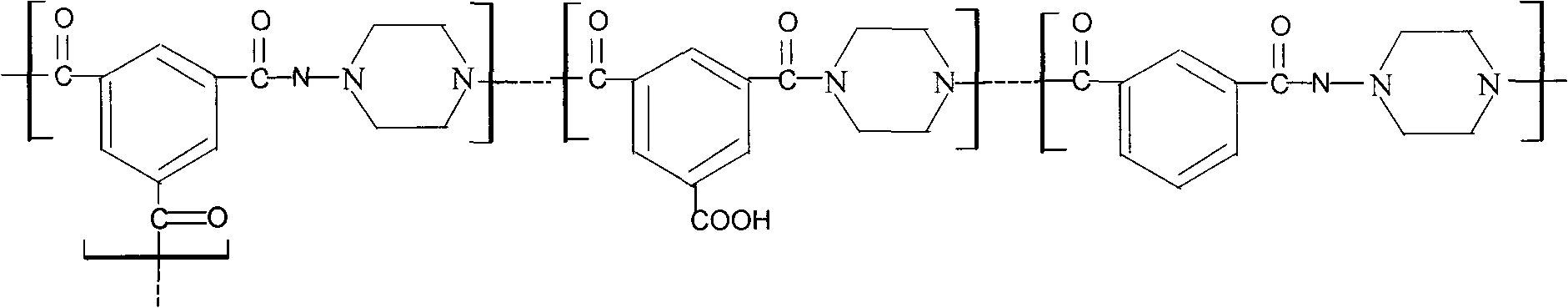

[0035] Preparation of composite nanofiltration membrane: immerse the wet polysulfone porous support membrane in the aliphatic macromolecular polyamine aqueous solution containing acid receiver for 2-8 minutes, roll the surface of the support membrane with a rubber roller, take out and drain the aqueous solution and use After drying with nitrogen, carry out single-sided interfacial polymerization with an organic solution containing a binary aromatic reactive monomer; the acid receiver is triethylamine, or sodium hydroxide, or sodium carbonate, or trisodium phosphate, with a content of 1.0-4.0wt%; the aliphatic macromolecular polyamine is polyvinylamine (PVAm), the content is 0.5-4.0wt%, the degree of ammonolysis is 0.1-0.9, and the molecular weight is 1000-500,000; the binary aromatic The reaction monomer is isophthaloyl chloride (IPC), or terephthaloyl chloride (TPC), or 2,4-toluene diisocyanate (TDI), and the content is 0.05-0.30wt%; the organic solvent used for the organic so...

Embodiment 1-3

[0043]Use 13.0wt% Udel PS3500 polysulfone, 0.25wt% water and 0.1wt% nonylphenol polyoxyethyl ester phosphate dissolved in N,N-dimethylformamide, and scrape on the polyester non-woven fabric and then immersed in water to remove the solvent to obtain a polysulfone porous support membrane with a molecular weight cut off of 100,000.

[0044] Immerse the wet polysulfone porous support membrane in an aqueous solution containing 3.0wt% triethylamine and 3.0wt% polyvinylamine (molecular weight = 28,000; degree of ammonolysis a = 0.53) for 5 minutes, and use a rubber roller to support Membrane surface, after draining the aqueous solution and blowing dry the support membrane surface with nitrogen, with 0.2wt% containing dibasic aromatic reaction monomer (respectively isophthaloyl dichloride (IPC), or terephthaloyl dichloride (TPC) , or 2,4-toluene diisocyanate (TDI)) in n-heptane solution was contacted on one side for interfacial polymerization for 120 seconds. The obtained composite m...

Embodiment 4-10

[0047] As in previous examples, according to the above method, an aqueous solution containing 3.0 wt% triethylamine and 0.5-4.0 wt% polyvinylamine (molecular weight=28,000; degree of ammonolysis a=0.53) was used, and 0.18 wt% m-benzene The n-heptane solution of diacid chloride (IPC) is contacted on one side to carry out interfacial polymerization reaction for 0.5-5 minutes to prepare a composite nanofiltration membrane. These examples are to investigate the influence of the weight ratio of polyacetamide in the aqueous solution on the performance of the composite nanofiltration membrane.

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com