Dust filtering performance testing method and system of air filter for cab of vehicle on road

An air filter and testing system technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of no air filter dust filtration performance, no testing equipment, etc., to improve product quality, The effect of improved production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

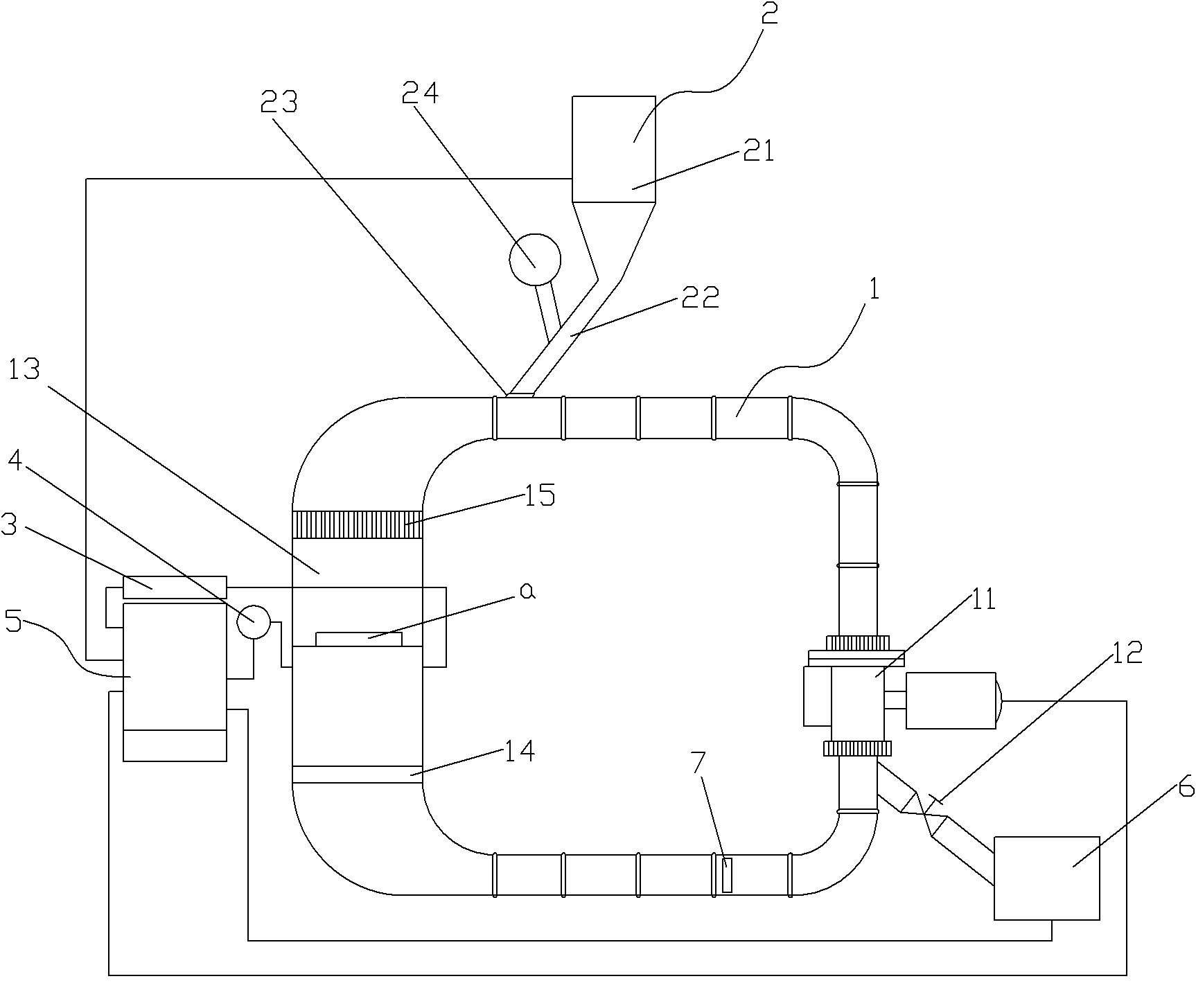

[0022] The road vehicle-cab air filter dust filtration performance test method of the present invention includes the filter element filtration efficiency test, that is, the dust particle concentration C1 before the test sample is installed and the dust particle after the test sample is installed The concentration C2 is measured, and the filtration efficiency (E) is calculated according to the formula (C1-C2) / C1*100%, that is, E=(C1-C2) / C1*100%.

[0023] In the filter efficiency test, it is divided into six grades according to the geometric diameter x (unit μm) of dust particles, which are 0.3≤x10.0, that is, each grade range corresponds to a filtration efficiency standard range.

[0024] The present invention adopts a hierarchical filtration efficiency testing method, which can simulate the actual working conditions more carefully and more realistically to test the filtration test of the air filter, thereby obtaining more accurate and reasonable test results; and the detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com