Syringe

A technology of syringes and nozzles, applied in the field of syringes, can solve the problems of splashing and expanding the degree of liquid medicine, and achieve the effect of easy avoidance and avoidance of wire drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

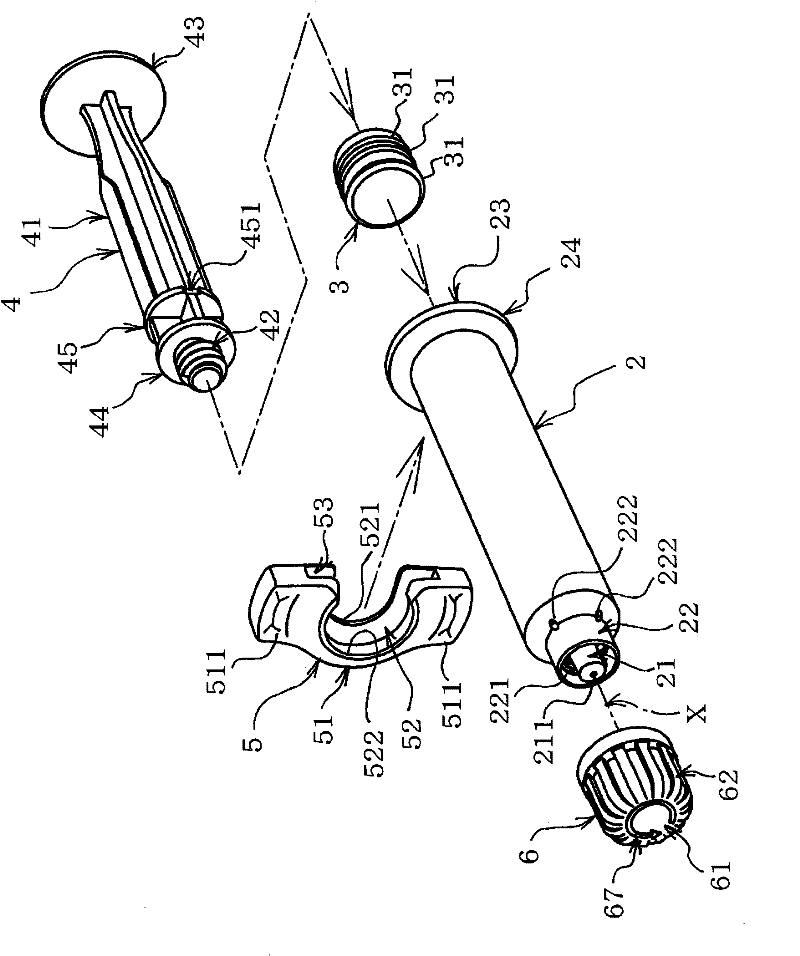

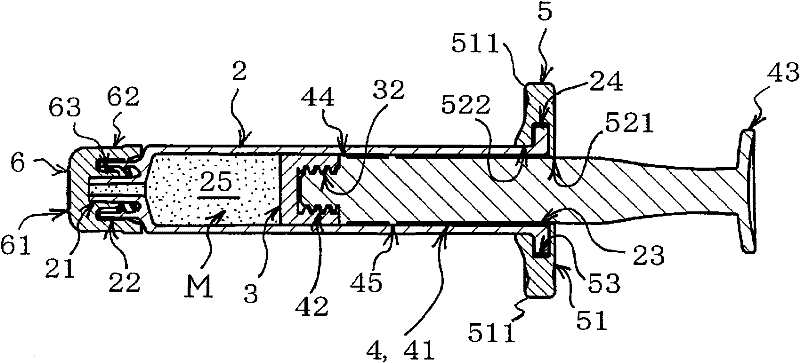

[0052] In addition, the present invention is not limited to the above-described embodiments, but includes other various embodiments. That is, in the above-mentioned embodiment, the case where the luer lock portion 22 is provided on the distal end side of the syringe cylinder 2 and the top cap 6 has the outer cylinder cover portion 62 covering the luer lock portion 22 has been shown, but the present invention is not limited thereto. Alternatively, the syringe may be configured without the aforementioned Luer lock portion 22, and the cap may be configured without the aforementioned outer cylinder cap portion 62. This is because the gist of the present invention lies in the respective structures of the tip nozzle 21 and the cap sealing portion 63 in the above-described embodiment.

Embodiment

[0054] Using a prefilled syringe having the basic shape of this embodiment filled with a high-viscosity drug solution, various combinations of the hole diameter of the tip opening and the sealing length of the top cap sealing part were tested and confirmed. Is there any snagging when pulling out the top cover?

[0055] As the syringe 2, the entire length range e of the inner hole 212 tip side starting from the tip opening 211 (refer to Figure 4 ), making 7 types of syringes with aperture D of 1.5mm, 1.3mm, 1.0mm, 0.7mm, 0.6mm, 0.5mm, and 0.4mm. On the other hand, as the top cap 6 , five kinds of top caps of 8.0 mm, 6.0 mm, 4.5 mm, 3.0 mm, and 2.0 mm in length S of the sealing portion of the top cap sealing portion 63 were manufactured.

[0056] The number of combinations of the hole diameter D and the length S of the sealing part is 7 (types) × 5 (types), that is, 35 types. Therefore, according to the 35 combinations, prepare 10 samples for each type, and fill them with B-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com