Piezoelectric ceramic wafer type isolating signal transformer and manufacturing method thereof

A technology of piezoelectric ceramics and manufacturing methods, which is applied in the field of transformers, can solve the problems of complex manufacturing, high cost, and unsafety of transformers, and achieve the effects of easy realization of large-scale production, easy manufacturing, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

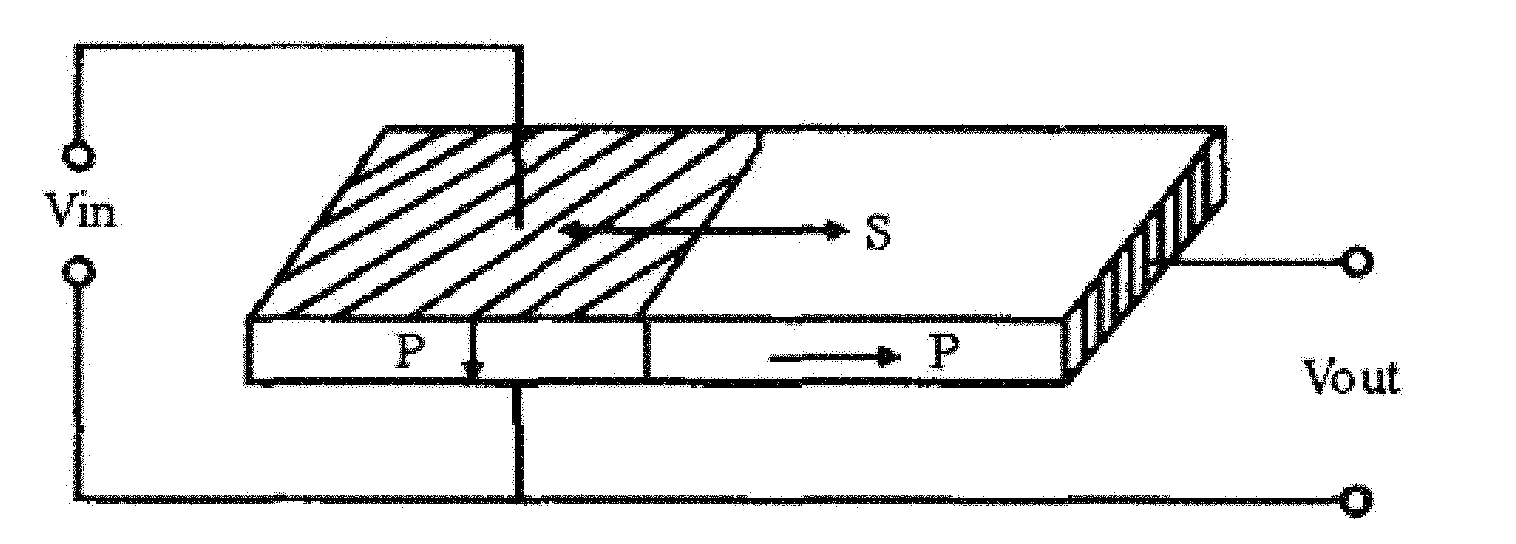

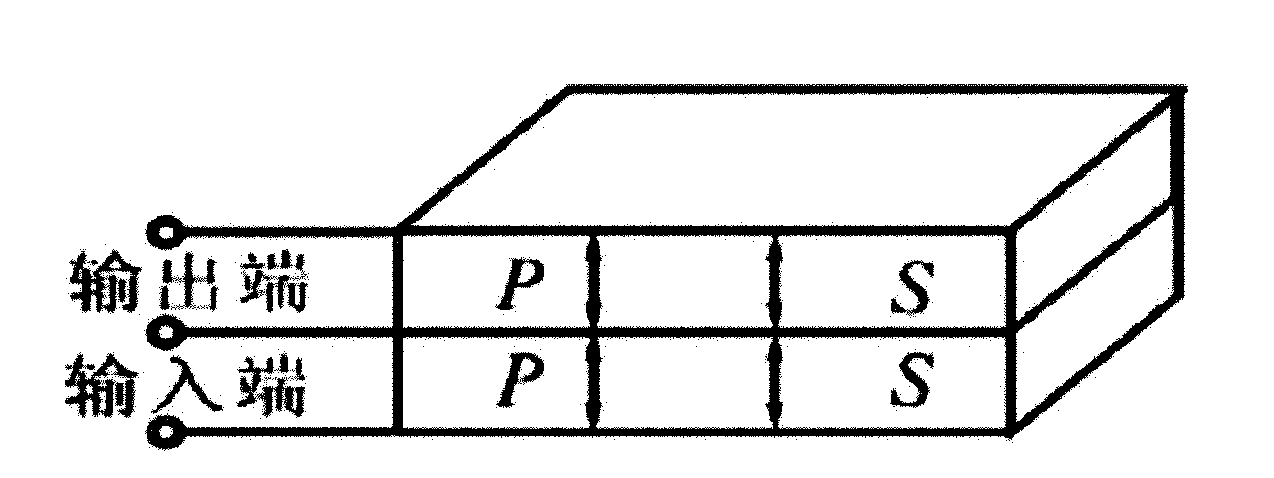

[0026] Fig. 4 is the specific embodiment of the present invention, as Pic 4-1 , Figure 4-2 , Figure 4-3 As shown, the piezoelectric ceramic isolation signal transformer is a wafer type, and mainly includes the following components: a ceramic body, an input part, an output part, a feedback part, and an isolation part.

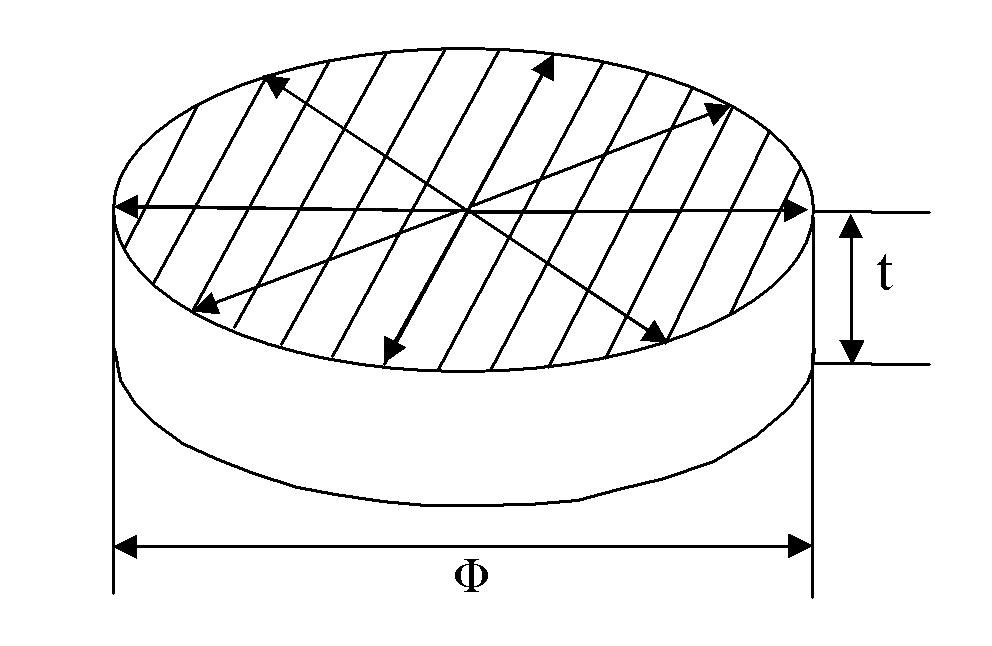

[0027] The isolation part is distributed symmetrically along the diameter of the disc-shaped blank, and extends from the upper circular surface to the lower circular surface along the thickness direction, dividing the piezoelectric ceramic blank into two parts, the input and the output, forming a gap between the input and output parts. The first isolation zone without electrodes; the width of the first isolation zone is 0.5-2mm; the left side of the first isolation zone is the input part, the upper surface is covered with the upper electrode of the input part, and the lower surface is covered with the lower electrode of the input part; the input The upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com