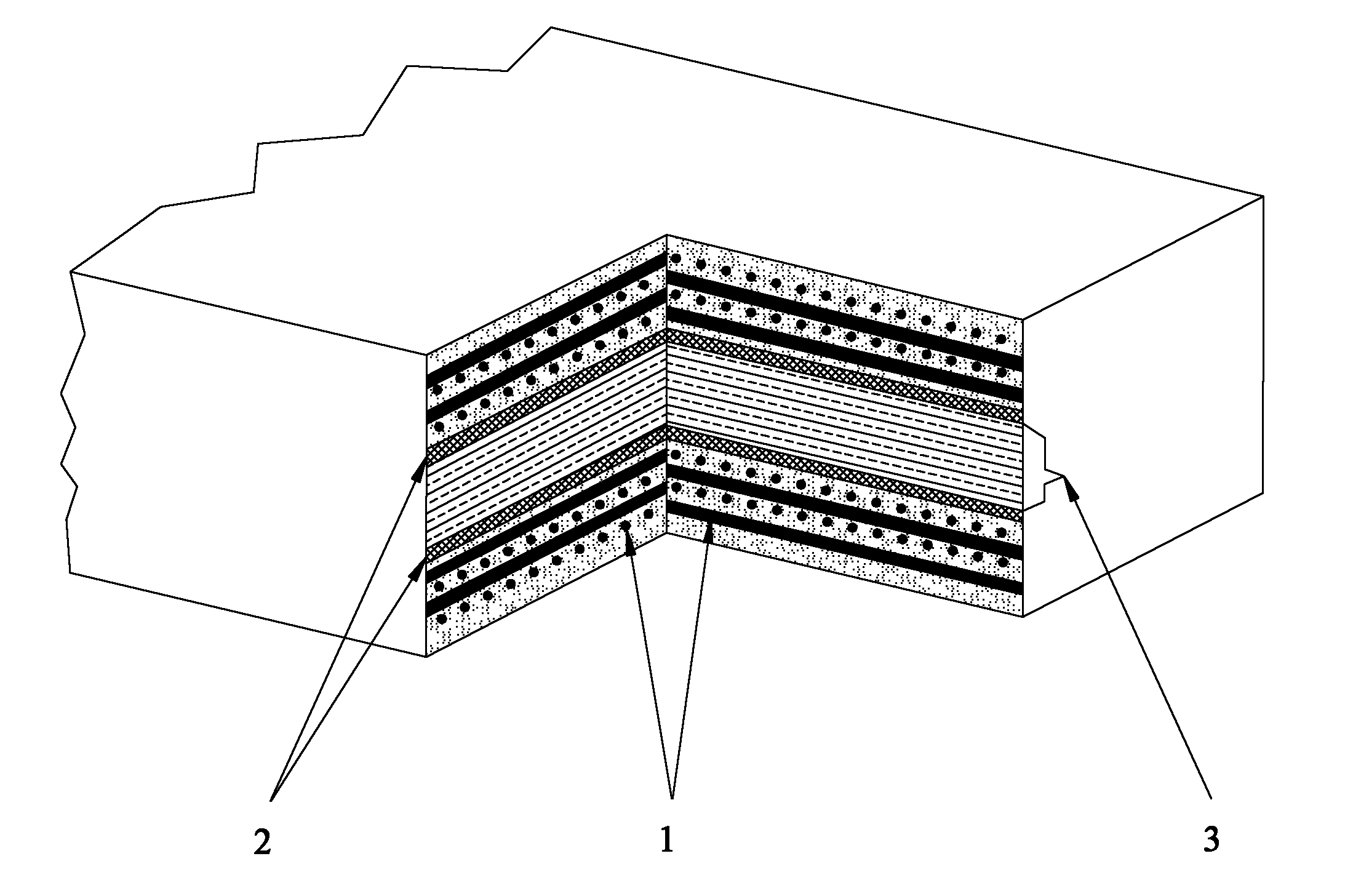

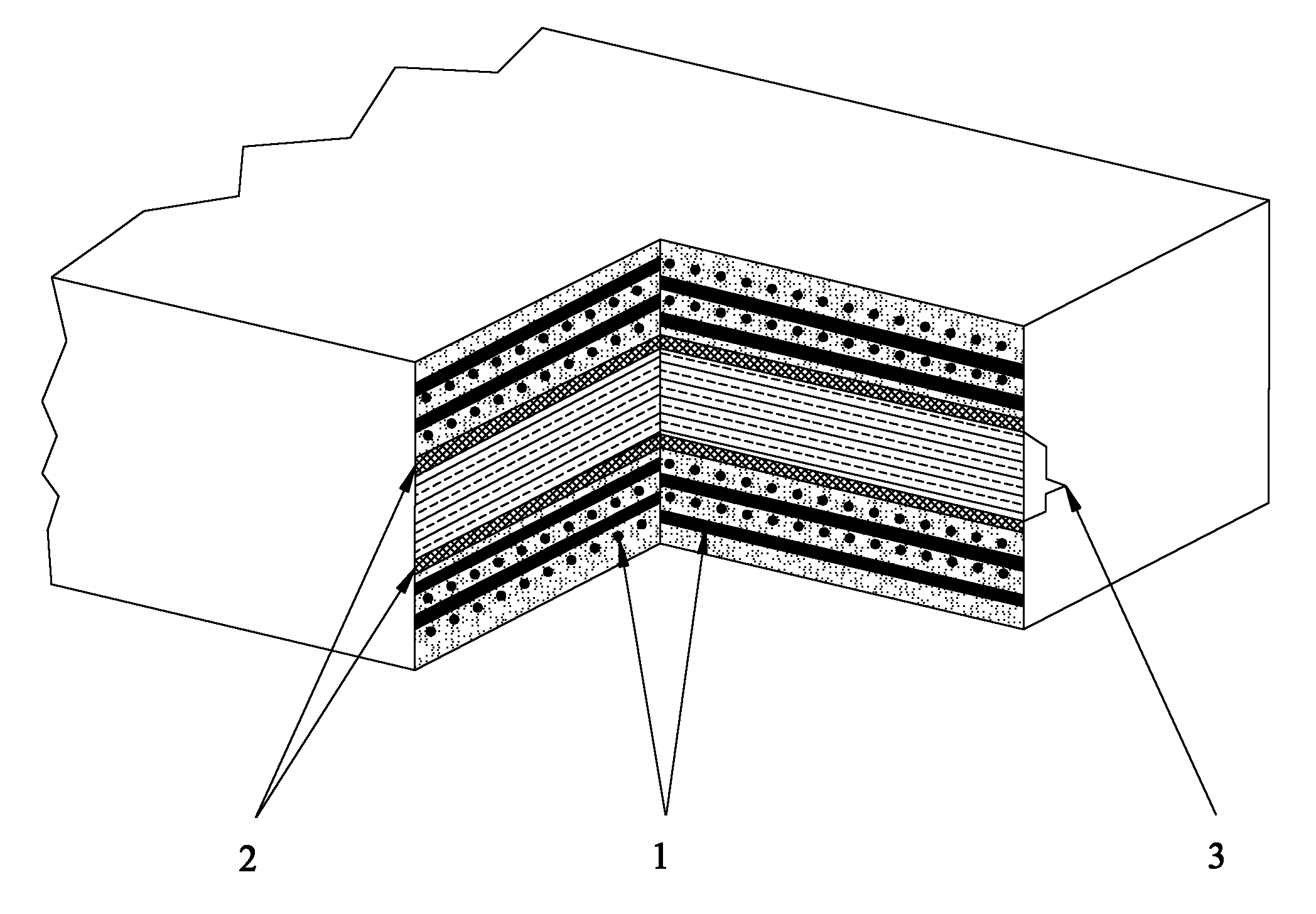

Building template reinforced by composite of continuous fiber plastic coated belt material and preparation method thereof

A continuous fiber and building formwork technology, applied in the on-site preparation of building components, sustainable construction, construction, etc., can solve the problems of inconvenient transportation, safety hazards, poor heat resistance, poor water resistance, etc., and achieve excellent compression and crack resistance. Anti-deformation characteristics, smooth and beautiful surface quality, reducing the effect of building support points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Material selection: The core board adopts the density of 0.65g / cm produced by Xuzhou Changqing Oriented Structural Board Co., Ltd. 3 , 12mm thick oriented strand board bonded with phenolic glue; the polymer adhesive film is a double-layer blown film with a thickness of 60 μm produced by Guangzhou Ala Bang Building Materials Co., Ltd., one of the surface layers is PPF800E resin from Shanghai Petrochemical Co., Ltd. The surface layer on the other side is Bynel 30E753 resin from DuPont in the United States; the continuous fiber unidirectional fabric is BUF13-280 (single fiber diameter 13 μm, surface density 280 g / m 2) of continuous basalt fiber warp-knitted unidirectional fabric; the plastic-coated strip is made of 085# homopolypropylene resin from Nanjing Oil Refinery, on the SZJP-CFM-80-1000 high-speed lamination laminating machine of Shantou Shanzhang Machinery Manufacturing Co., Ltd. The continuous fiber unidirectional fabric is coated on both sides with film coating, ...

Embodiment 2

[0037] Material selection: The core board adopts the density of 0.65g / cm produced by Xuzhou Changqing Oriented Structural Board Co., Ltd. 3 , 12 mm thick oriented strand board bonded with phenolic adhesive; the polymer adhesive film is a three-layer cast film with a thickness of 50 μm produced by Shanghai Meifeng Packaging Materials Co., Ltd., and one of the surface layers is C1007 produced by Shanghai Secco Petrochemical Co., Ltd. Resin, the other surface layer is ADMER QF551 resin from Mitsui Chemicals; the continuous fiber unidirectional fabric adopts Nantong Tongmao New Material Industry and Trade Co., Ltd. brand GU450 (single fiber diameter 16μm, surface density 450g / m 2 ) continuous glass fiber warp-knitted unidirectional fabric; the plastic-coated strip is made of PPK7726 copolymerized polypropylene resin from Beijing Yanshan Petrochemical Company, and is continuously coated on the SZJP-CFM-80-1000 high-speed lamination laminating machine of Shantou Shanzhang Machinery M...

Embodiment 3

[0041] Material selection: The core board adopts the density of 0.65g / cm produced by Xuzhou Changqing Oriented Structural Board Co., Ltd. 3 , 15 mm thick oriented strand board bonded with melamine glue; the polymer adhesive film is a double-layer blown film with a thickness of 60 μm produced by Guangzhou Ala Bang Building Materials Co., Ltd., and one surface layer is PPFS00E resin of Shanghai Petrochemical Co., Ltd. The surface layer on the other side is Bynel 30E753 resin from DuPont in the United States; the continuous fiber unidirectional fabric is BUF13-280 (single fiber diameter 13 μm, surface density 280 g / m 2 ) of continuous basalt fiber warp-knitted unidirectional fabric; the plastic-coated strip is made of 085# homopolypropylene resin from Nanjing Oil Refinery, on the SZJP-CFM-80-1000 high-speed lamination laminating machine of Shantou Shanzhang Machinery Manufacturing Co., Ltd. The continuous fiber unidirectional fabric is coated on both sides with film coating, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com