Spraying device for cool transfer printing machine

The technology of a spray device and a transfer printing machine is applied in the field of garment machinery, which can solve the problems of troublesome operation, high energy consumption, pollution of the processing workshop environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

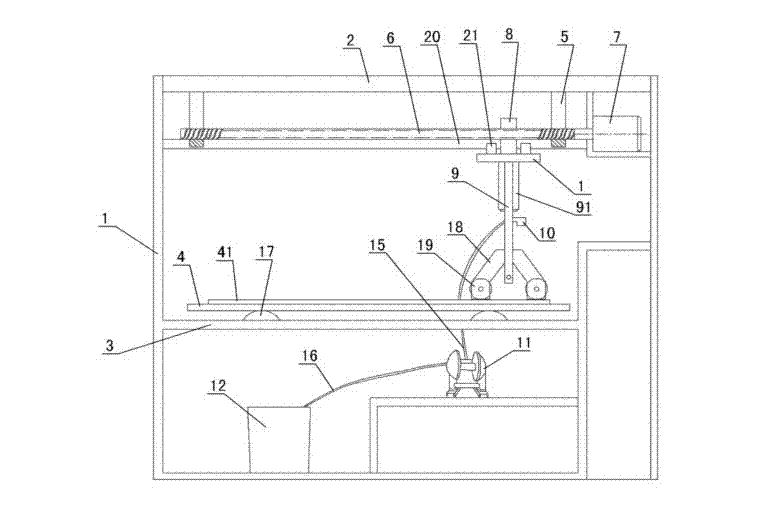

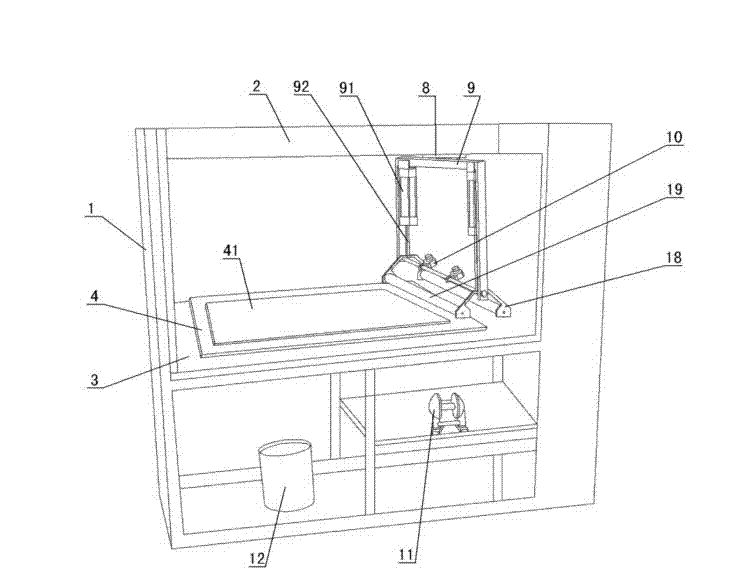

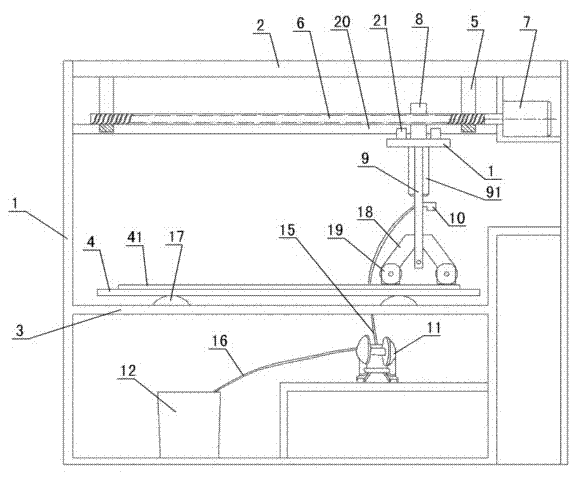

[0009] The invention relates to a spray device of a cold transfer machine, such as figure 1 , figure 2 As shown, it is characterized in that it comprises a frame 1, the top of the frame is shaped on a crossbeam 2, the middle part of the frame is shaped on an operating platform 3, a working platform 4 is placed on the operating platform 3, cotton fabric 41 is laid on the working platform 4, and the crossbeam 2 Screw rod fixing block 5 is installed on the top, screw rod 6 is installed in the screw rod fixing block, screw rod 6 is driven by motor 7, spray moving block 8 is installed on screw rod 6, spray bracket 9 is installed under the spray moving block, and spray bracket 9 is installed Spray nozzle 10, spray nozzle 10 connects spray pump 11 through spray tube 15, spray pump 11 connects active dye barrel 12 through leather tube 16, spray nozzle 10 carries out reactive dye spray to the cotton fabric 41 that is laid on the working plate 4, cotton fabric 41 has a reactive dye hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com