A new spray device for cold transfer printing machine

A technology of spraying device and transfer printing machine, which is applied to the general parts of printing machinery, printing machines, printing, etc. It can solve the problems of uncontrollable humidity and troublesome operation, and achieve the effects of precise humidity control, uniform spraying and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

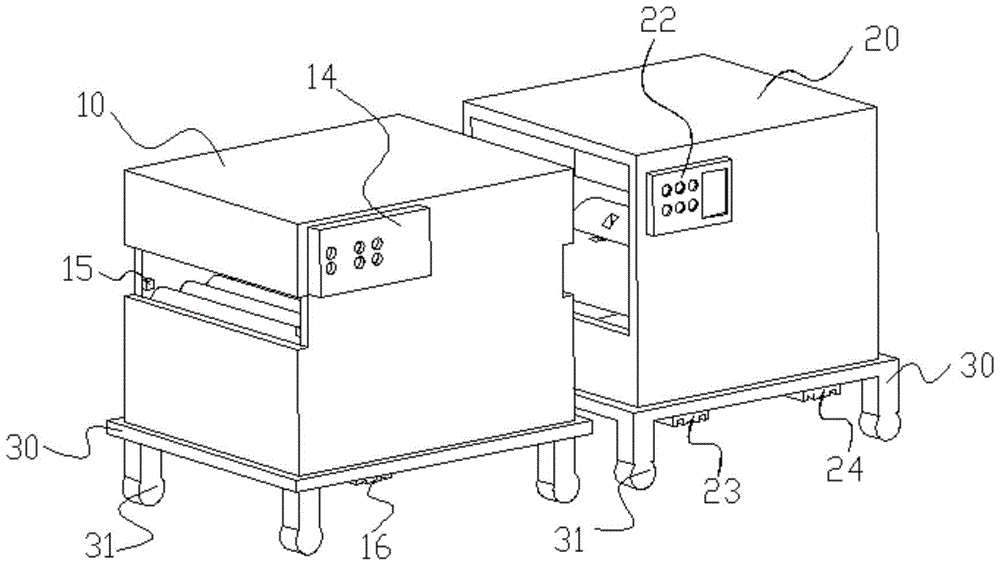

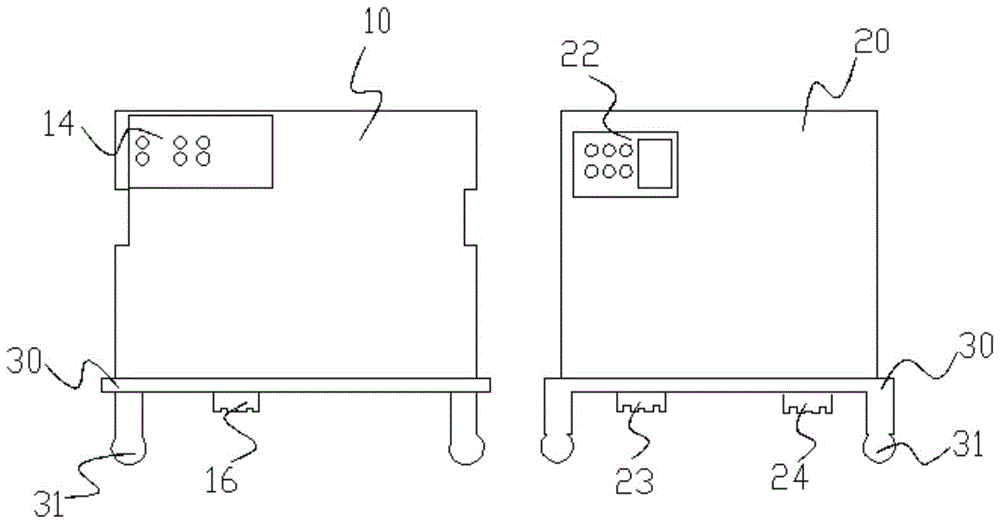

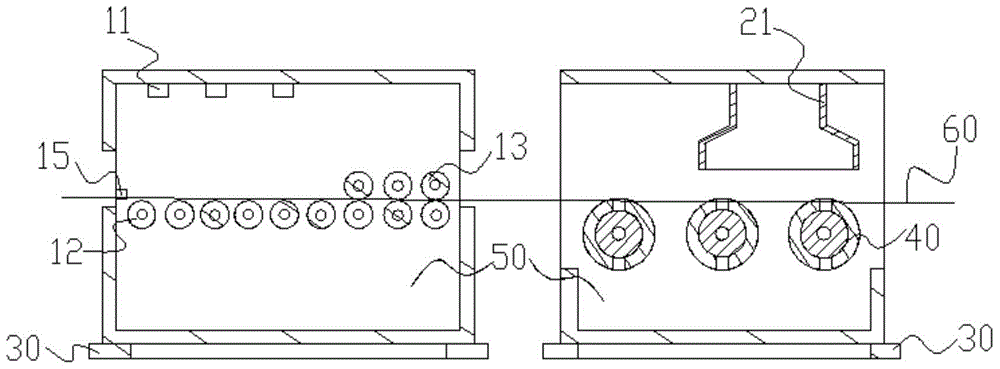

[0022] See Figure 1 to Figure 4 As shown, a novel spraying device of a cold transfer machine includes a spray box 10 and a wet control box 20, and the spray box 10 and the wet control box 20 are respectively arranged on a support 30, and the spray box Several cloth rollers 12 are arranged between the cloth inlet and the cloth outlet of 10, and the cloth rollers 12 are sleeved on the rotating shaft and driven by the cloth roller motor 16, and several spray heads 11 and pressure rollers are arranged above the cloth rollers 12. Roller 13, the spray head 11 is fixedly arranged on the top surface of the spray box body 10 and is arranged close to the cloth inlet of the spray box body 10, the pressure roller 13 is sleeved on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com