Yellow health-preserving milk and preparation method thereof

A milk and compound stabilizer technology, which is applied in the field of yellow health milk and its preparation, can solve the problem of no patent query

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

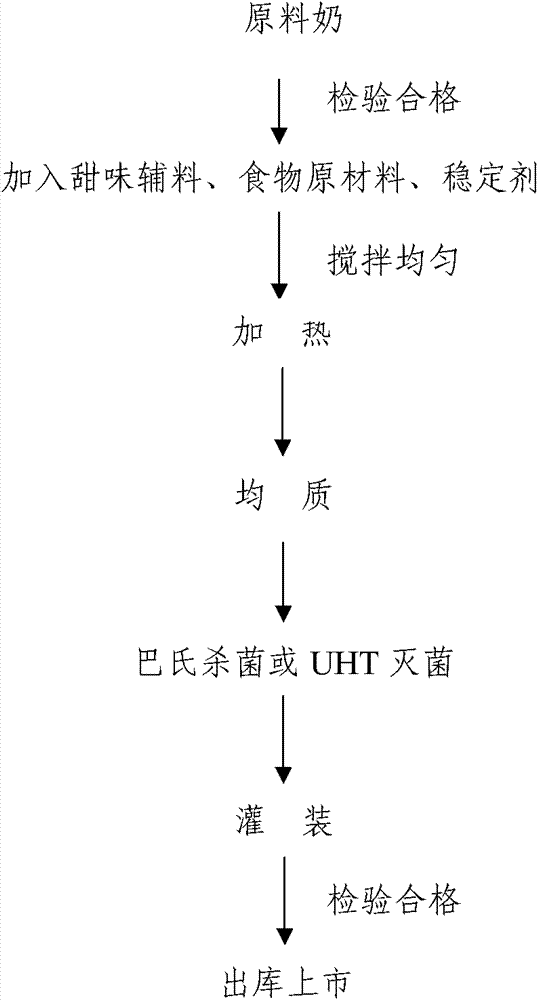

Method used

Image

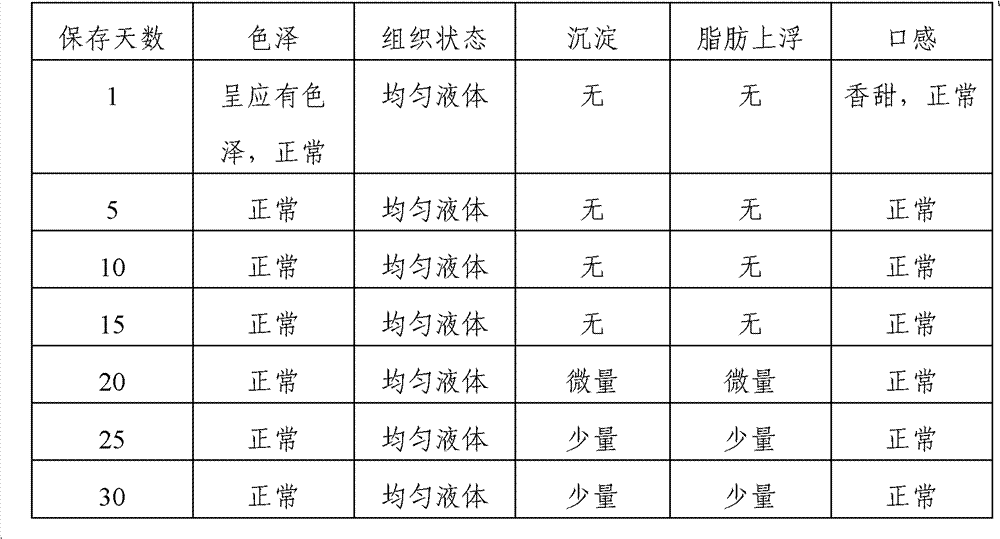

Examples

Embodiment 1

[0036] Example 1 Yellow health milk · surplus (papaya + yellow peach)

[0037] 6% papaya pulp, 6% yellow peach pulp, 4.5% white granulated sugar and 0.15% compound stabilizer (containing 0.04% glyceryl monostearate, 0.03% sucrose fatty acid ester, 0.02% polyglycerol fatty acid ester, yellow 0.015% raw gum, 0.015% carrageenan, 0.015% sodium alginate, 0.015% sodium carboxymethyl cellulose) were mixed, and added to milk at 60° C., and the amount of milk added was 80%. After stirring for 20 minutes to fully dissolve the material, add water to make up to 100%. Heated to 60°C, homogenized under 200bar pressure, sterilized by UHT at 137°C / 4 seconds, made by aseptic filling, and packaged in the form of Baili bag.

Embodiment 2

[0038] Example 2 Yellow health milk · surplus (pumpkin + carrot + millet)

[0039]5% pumpkin powder, 5% carrot powder, 4% millet powder, 3% white granulated sugar, 0.002% sucralose and 0.2% compound stabilizer (containing 0.05% glyceryl monostearate, 0.05% sucrose fatty acid ester, 0.02% xanthan gum, 0.02% carrageenan, 0.02% sodium carboxymethyl cellulose, 0.02% sodium alginate, 0.01% gellan gum, 0.01% sodium tripolyphosphate) mixed, added to 52 ° C milk, milk The added amount is 80%. After stirring for 20 minutes to fully dissolve the material, add water to make up to 100%. Heated to 62°C, homogenized under 200bar pressure, pasteurized at 85°C / 15 minutes, made by ultra-clean filling, and packaged in Ecolean packaging.

Embodiment 3

[0040] Example 3 Yellow health milk · surplus (pumpkin + hazelnut + chestnut)

[0041] 5% pumpkin powder, 5% hazelnut powder, 3% chestnut powder, 4.5% white sugar and 0.2% compound stabilizer (containing 0.04% glyceryl monostearate, 0.04% sucrose fatty acid ester, polyglycerol fatty acid ester 0.02%, xanthan gum 0.02%, carrageenan 0.02%, sodium alginate 0.02%, sodium carboxymethyl cellulose 0.02%, gellan gum 0.01%, sodium tripolyphosphate 0.01%) mixed, added to 55 ℃ milk In, the addition amount of milk is 80%. After stirring for 15 minutes to fully dissolve the material, add water to make up to 100%. Heated to 65°C, homogenized by 250bar pressure, sterilized by UHT at 137°C / 4 seconds, made by aseptic filling, and packaged in the form of aseptic bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com