High-frequency heating device and high-frequency heating method

A high-frequency heating device and high-frequency technology are applied in the direction of electric heating devices, microwave heating, ohmic resistance heating, etc., which can solve the problems of time-consuming and achieve the effect of shortening time and improving irradiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

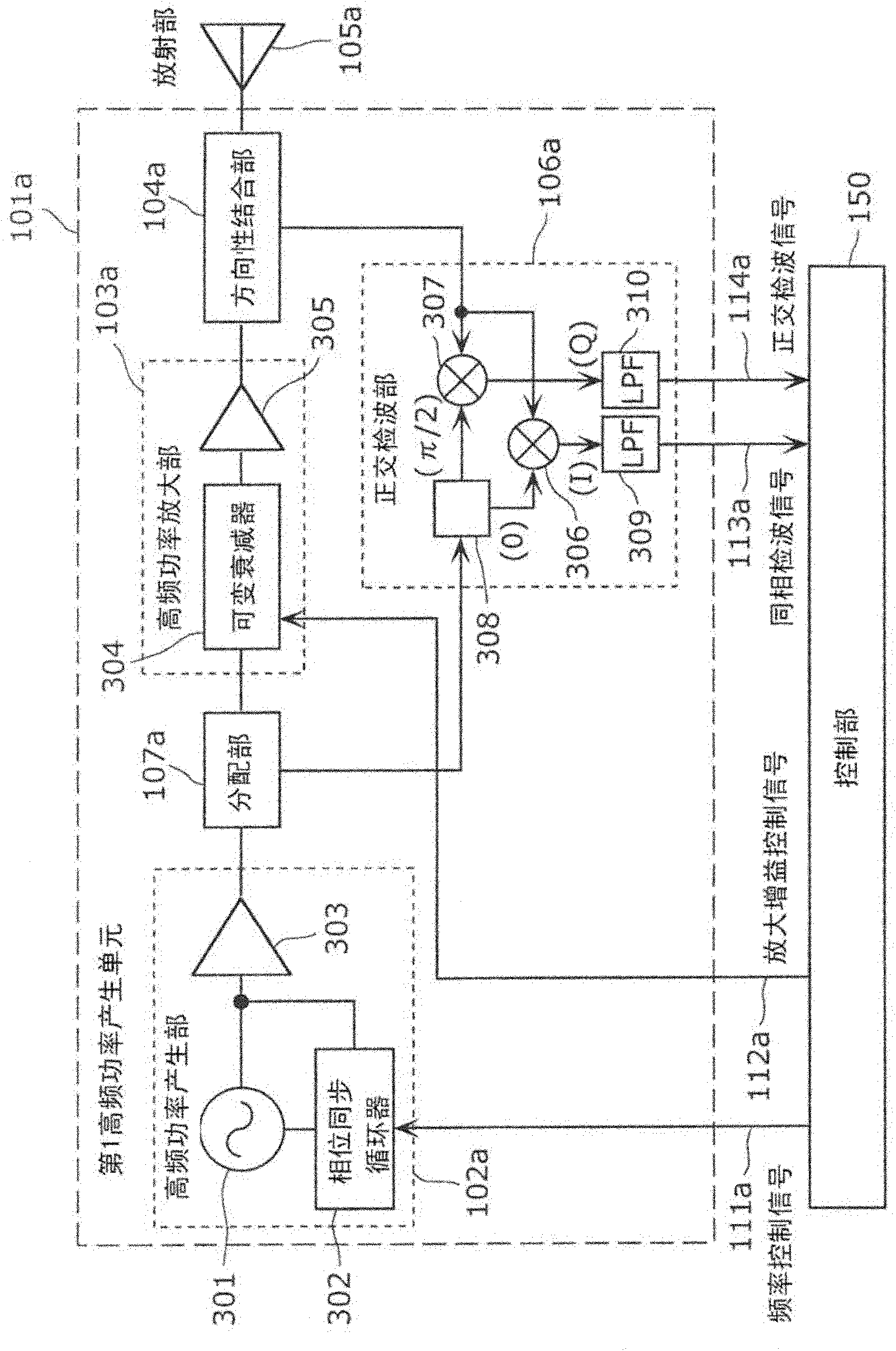

[0045] Next, a first embodiment of the present invention will be described with reference to the drawings.

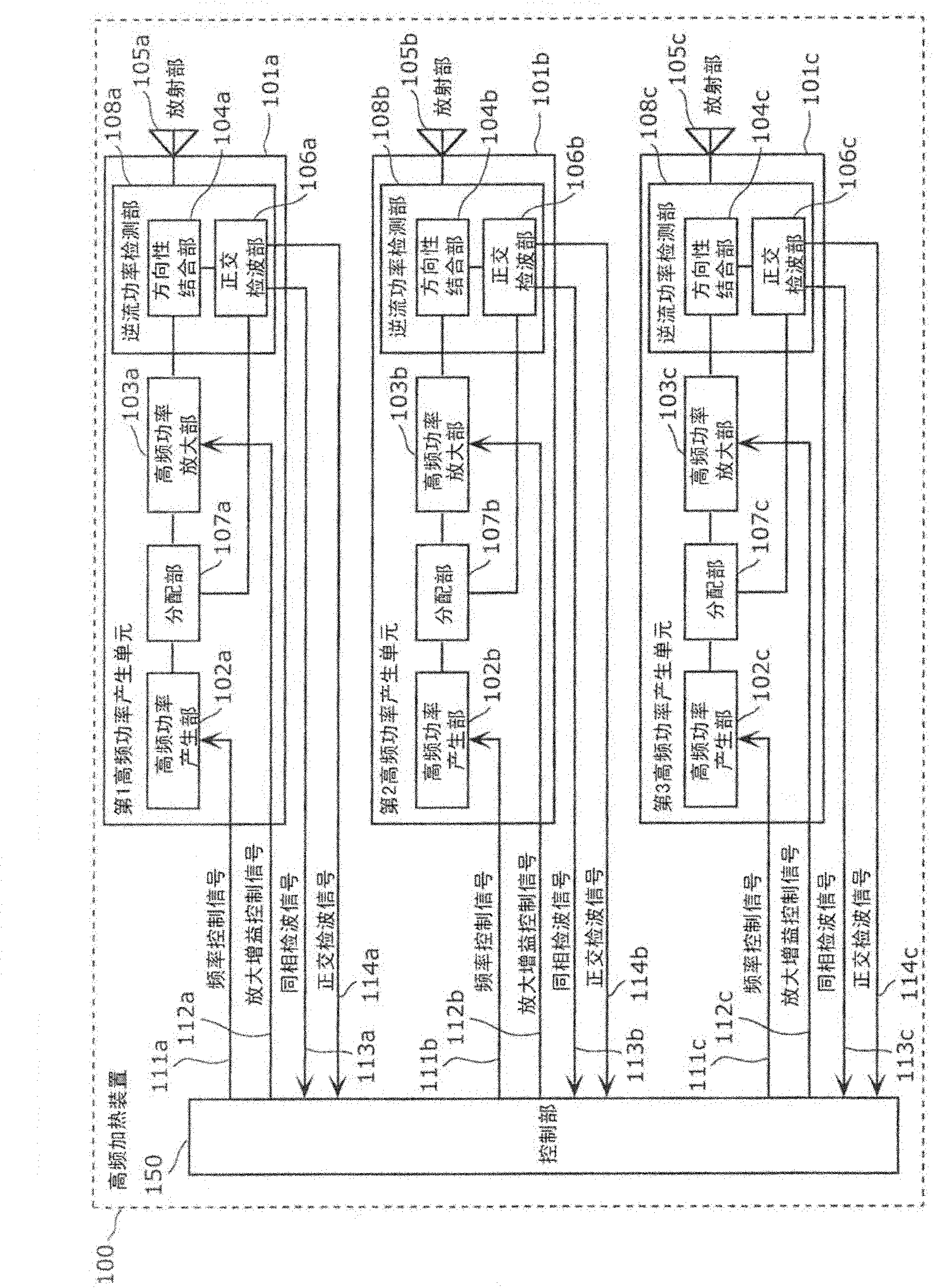

[0046] figure 1 It is a block diagram showing the configuration of the high-frequency heating device of the present invention.

[0047] The high-frequency heating device 100 has a first high-frequency power generation unit 101 a , a second high-frequency power generation unit 101 b , a third high-frequency power generation unit 101 c , and a control unit 150 . In addition, the first high-frequency power generation unit 101a, the second high-frequency power generation unit 101b, and the third high-frequency power generation unit 101c are sometimes described as the high-frequency power generation unit 101a, the high-frequency power generation unit 101b, and the high-frequency power generation unit 101b below. Power generating unit 101c. In addition, the high-frequency heating device 100 also has a heating chamber for accommodating an object to be heated.

[0048] The h...

no. 2 Embodiment approach

[0225] Next, a second embodiment of the present invention will be described with reference to the drawings.

[0226] This embodiment differs from the first embodiment in that each radio-frequency power generation unit has two radio-frequency power generation units instead of distribution units. According to such a configuration, the detection accuracy of the reverse flow power detected by the reverse flow power detection unit can be improved by appropriately setting the frequencies of the two high-frequency power generation units.

[0227] The following description will focus on differences from the first embodiment. In addition, in the description of this embodiment, the components having the same functions as those of the first embodiment are assigned the same reference numerals, and description thereof will be omitted. In addition, the description of the same operation as that of the first embodiment is also omitted.

[0228] Figure 11 It is a block diagram showing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com