Circuit and method for detecting inductance peak current of DC-DC (direct current-direct current) converter

A technology of DC-DC and converter circuits, which is applied in the detection circuit field of input peak current in DC-DC converters, to achieve the effect of improving performance and increasing chip cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

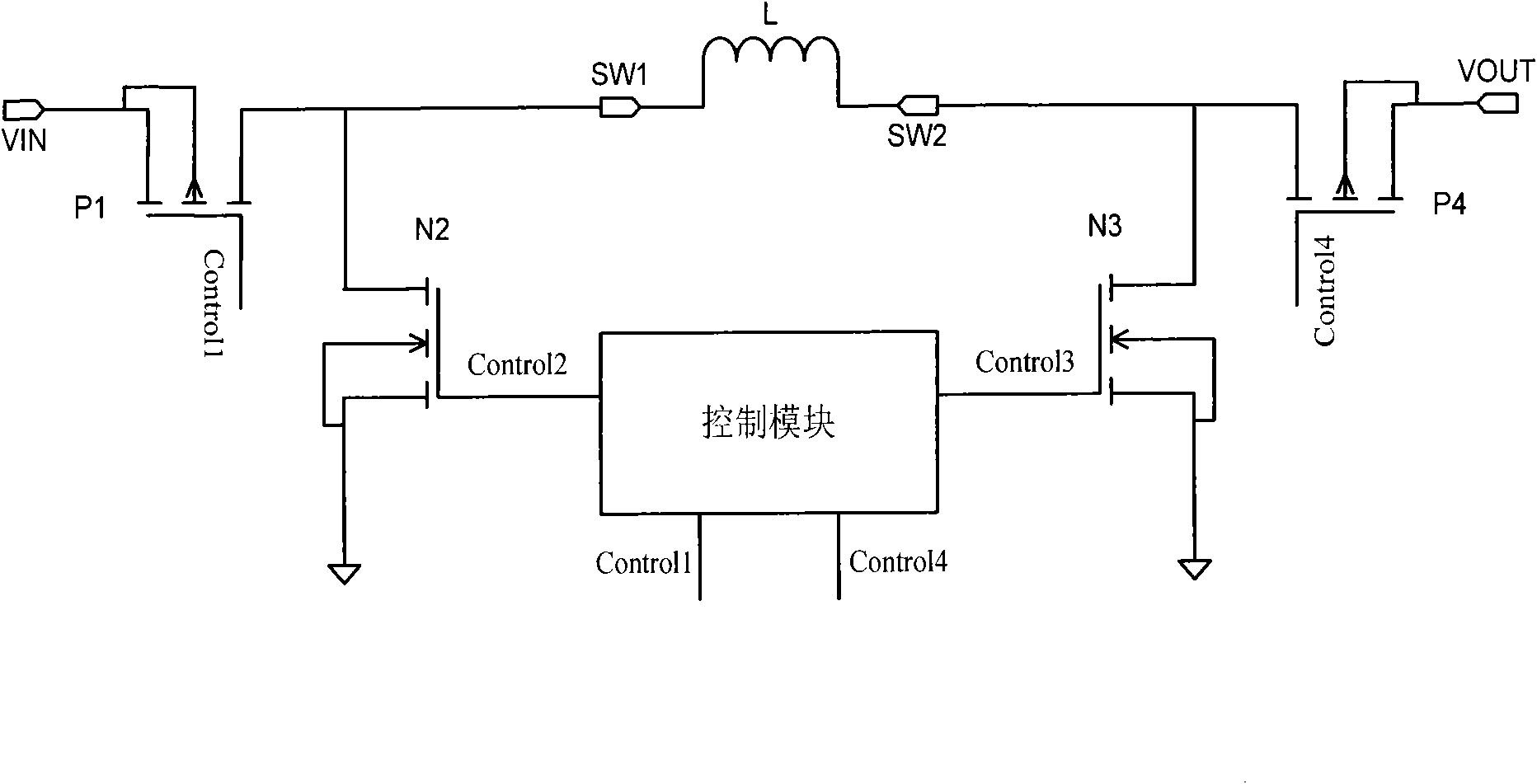

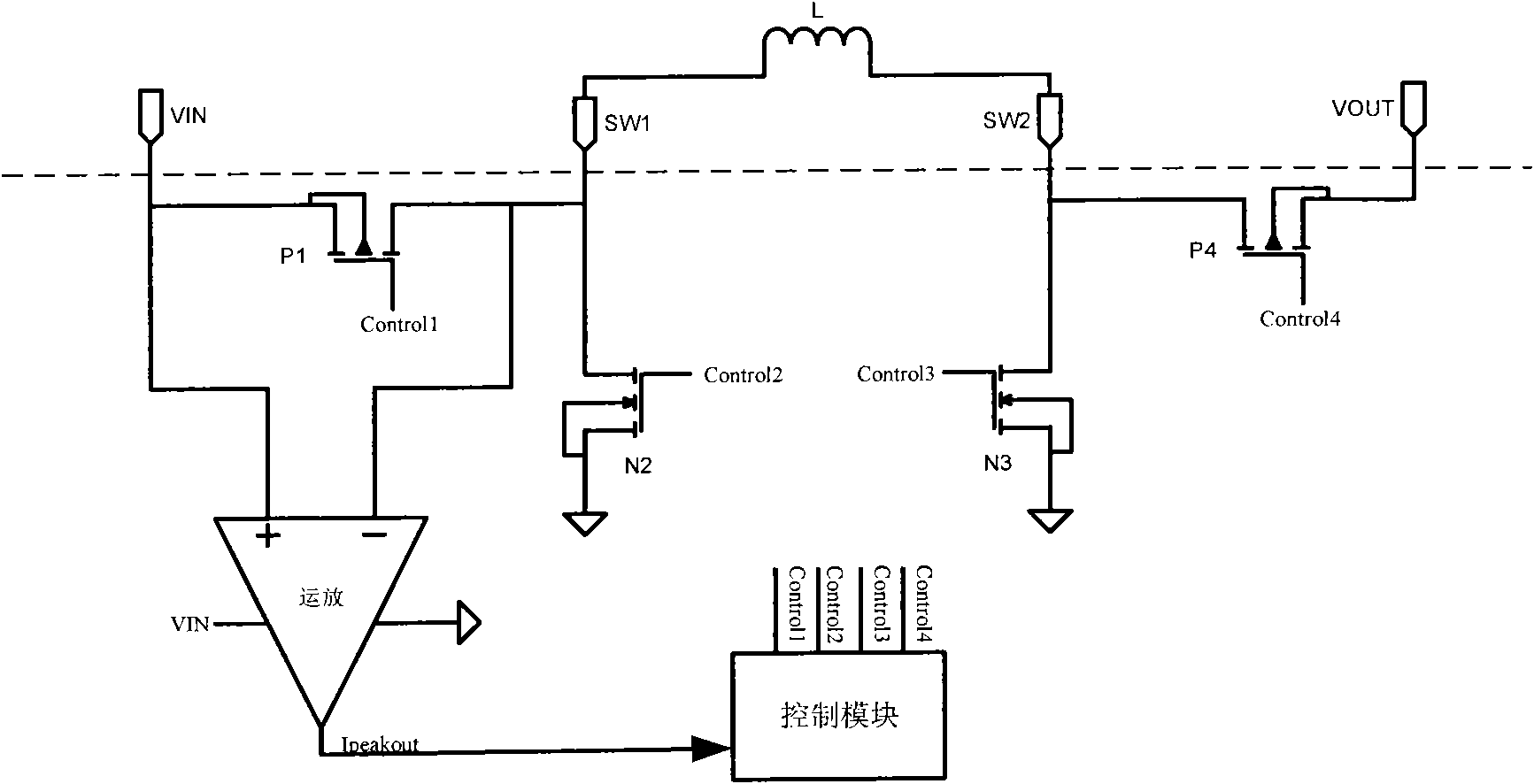

[0023] The present invention provides a detection circuit and detection method for detecting the peak current of the inductor in a DC-DC converter, such as image 3 As shown, the detection circuit includes a DC-DC converter circuit, a peak current detection circuit that detects the inductor peak current in the converter circuit, and a control circuit that generates a feedback control signal. The DC-DC converter circuit includes power switch tubes P1, P4, N2, and N3, an inductor L, an input voltage VIN terminal and an output voltage VOUT terminal, and the first power switch tube P1 is connected to the input voltage VIN terminal. The peak current detection circuit includes a mirror tube P5 that mirrors the current flowing through the first power switch tube P1 in a certain ratio, a detection resistor Rsenser connected in series with the mirror tube P5, and an operational amplifier AMP.

[0024] After the mirror tube P5 and the detection resistor Rsenser are connected in series, they...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com