Magnetic conductive wire as well as electronic equipment and manufacturing method thereof

A technology of electronic equipment and magnetic wire, applied in the field of magnetic wire, can solve the problems of overcoming eddy current, resistance drop, inability to overcome proximity effect and skin effect, etc., and achieve the effect of suppressing the formation of eddy current and reducing AC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Instructions for materials and equipment used:

[0047] 1. Polyurethane coating: Produced by ASEAN Chemical Industry, model PU-130-45, viscosity at 30°C is 0.5 Pa·s (Pa·s), solid content 45%.

[0048] 2. γ-Fe2O3: produced by Japan Titan Kogyo Company, model γ-MRD, with an axial length of 0.5 μm and an axial ratio of 7.

[0049] 3. Oleic acid: produced by Japan Shimahisa Co., Ltd., CAS No.112-80-1, concentration 98%.

[0050] 4. Inductance, capacitance and resistance measuring instrument (LCR Meter): manufactured by Agilent, USA, model E4980A, the test frequency range is 20Hz to 2MHz.

Embodiment 1

[0059] Add 20 parts of γ-Fe2O3 to 100 parts of polyurethane paint, knead in a ball mill for 24 hours to make a magnetic paint, and apply a single layer on a copper material with a wire diameter of 0.31 mm to make a wire sample according to the following conditions. The characteristics of the finished product are shown in Table 1. Show.

[0060] Coating method: eye mold

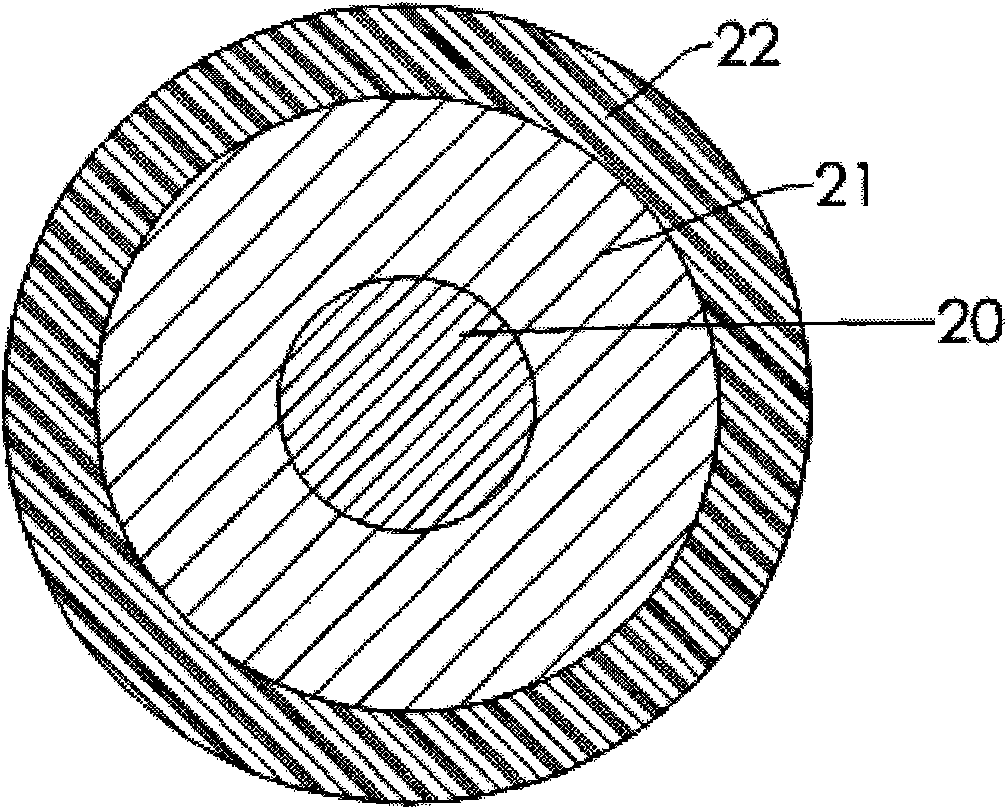

[0061] Coating times: Alternately apply magnetic paint 5 times and polyurethane paint 5 times (such as figure 2 shown)

[0062] Line speed: 60-70 m / min

[0063] Baking oven temperature: 440-500°C

Embodiment 2

[0065] After modifying the surface of 20 parts of γ-Fe2O3 with 5 parts of oleic acid, add 100 parts of polyurethane paint together, and mix it with a ball mill for 24 hours to make a magnetic paint. According to the conditions of Example 1, a single layer is coated on a copper wire with a wire diameter of 0.31 mm. The wire samples were made on the material, and the characteristics of the finished products are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com