Bending fatigue test machine for steel wire rope in case of alternating load

A technology of bending fatigue and steel wire rope, which is applied in the field of equipment in the field of testing technology, can solve the problem that the actual life of the test results of bending fatigue life of the steel wire rope is too different, it is not suitable for the prediction of the service life of the steel wire rope of the deep well friction hoist, and it cannot simulate the reality of the friction hoisting wire rope Working conditions and other issues to achieve the effect of improving safety and efficiency, simple structure, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

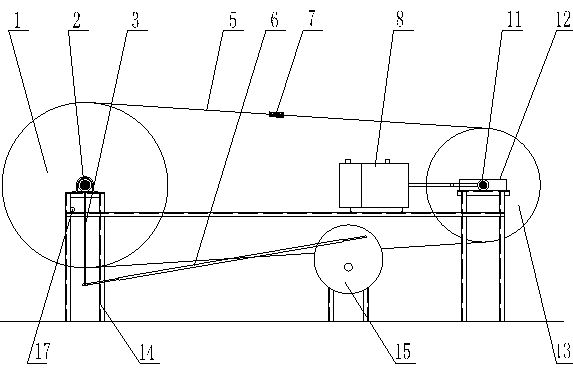

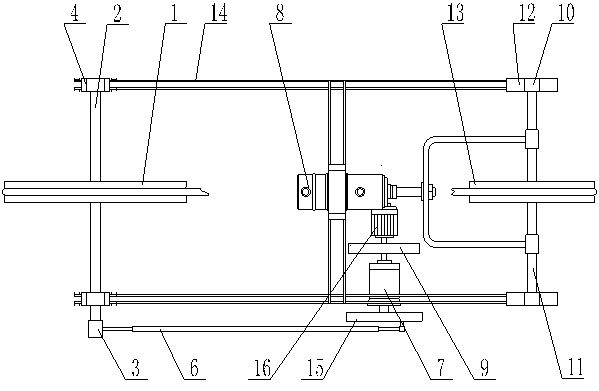

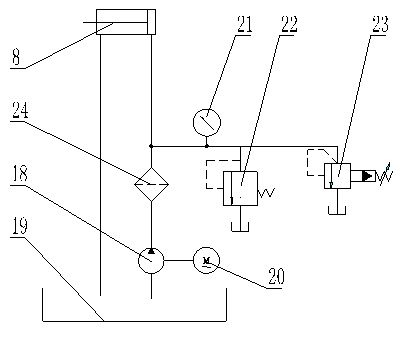

[0013] An embodiment of the invention will be further described below in conjunction with the accompanying drawings:

[0014] Such as figure 1 , 2 As shown, the steel wire rope variable load bending fatigue testing machine of the present invention is mainly composed of frame 14, driving wheel 1, drive shaft 2, tensioning shaft 11, tensioning wheel 13, steel wire rope 5, driving device, electro-hydraulic servo system, tensioning Mechanism and proximity switch 17 constitute, driving wheel 1 and tensioning wheel 13 are in the same vertical plane, and wire rope test piece 5 is wound on driving wheel 1 and tensioning wheel 13. Frame 14 is welded by section steel, symmetrical left and right, drive shaft 2 is fixed on the left side of frame 14 through bearing seat 4, tensioning shaft 11 is arranged in the guide groove 12 on the right side of frame 14 through limit bearing 10, The driving wheel 1 and the tensioning wheel 13 are arranged in the middle of the driving shaft 2 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com