Main brake valve with electronic-control pneumatic-control dual-circuit signals

A brake master valve, dual-circuit technology, applied in the direction of control valve and bleed valve, brake, brake components, etc., can solve dangerous accidents, brake system can not effectively control brake line pressure changes, vehicle braking and other issues to achieve high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

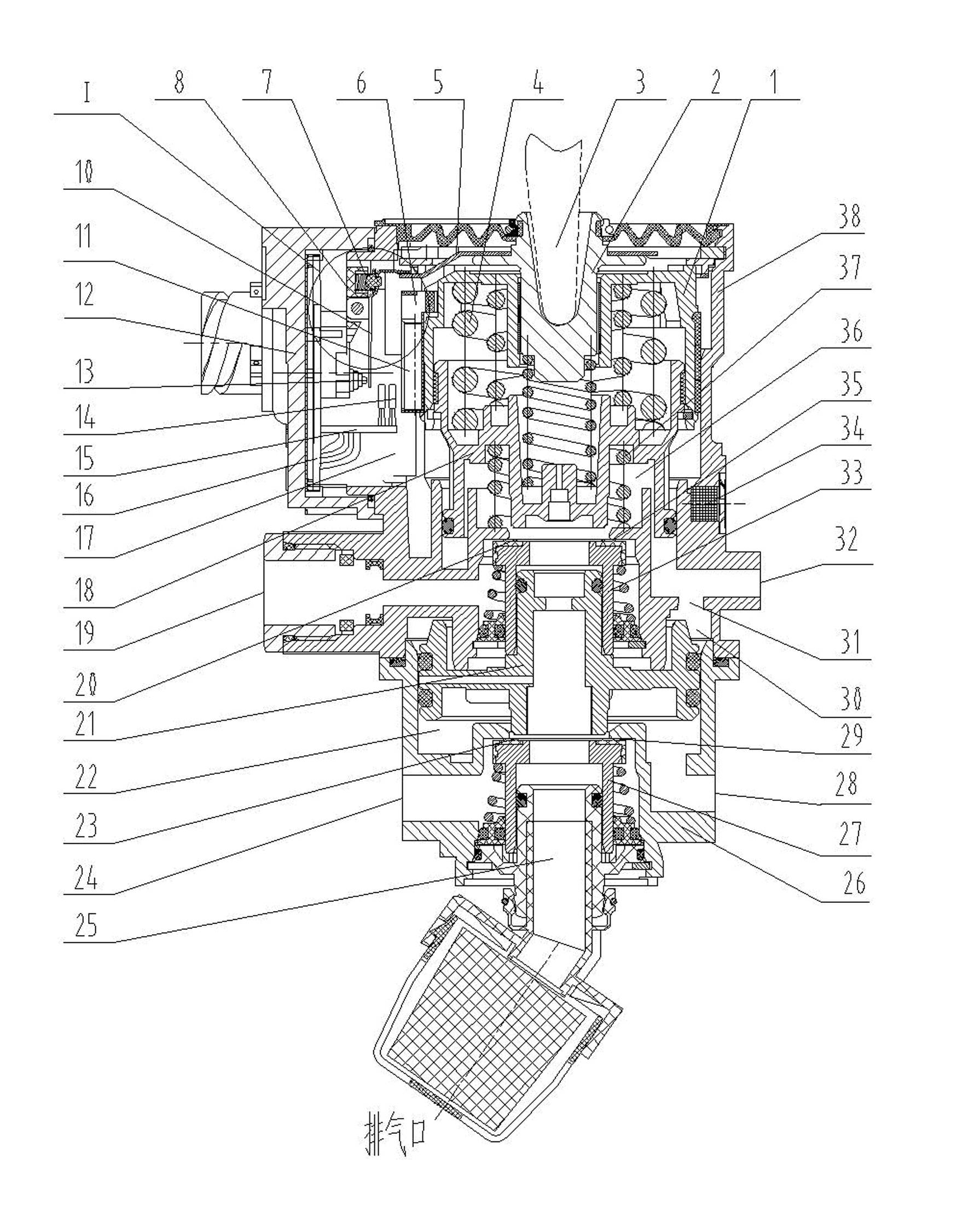

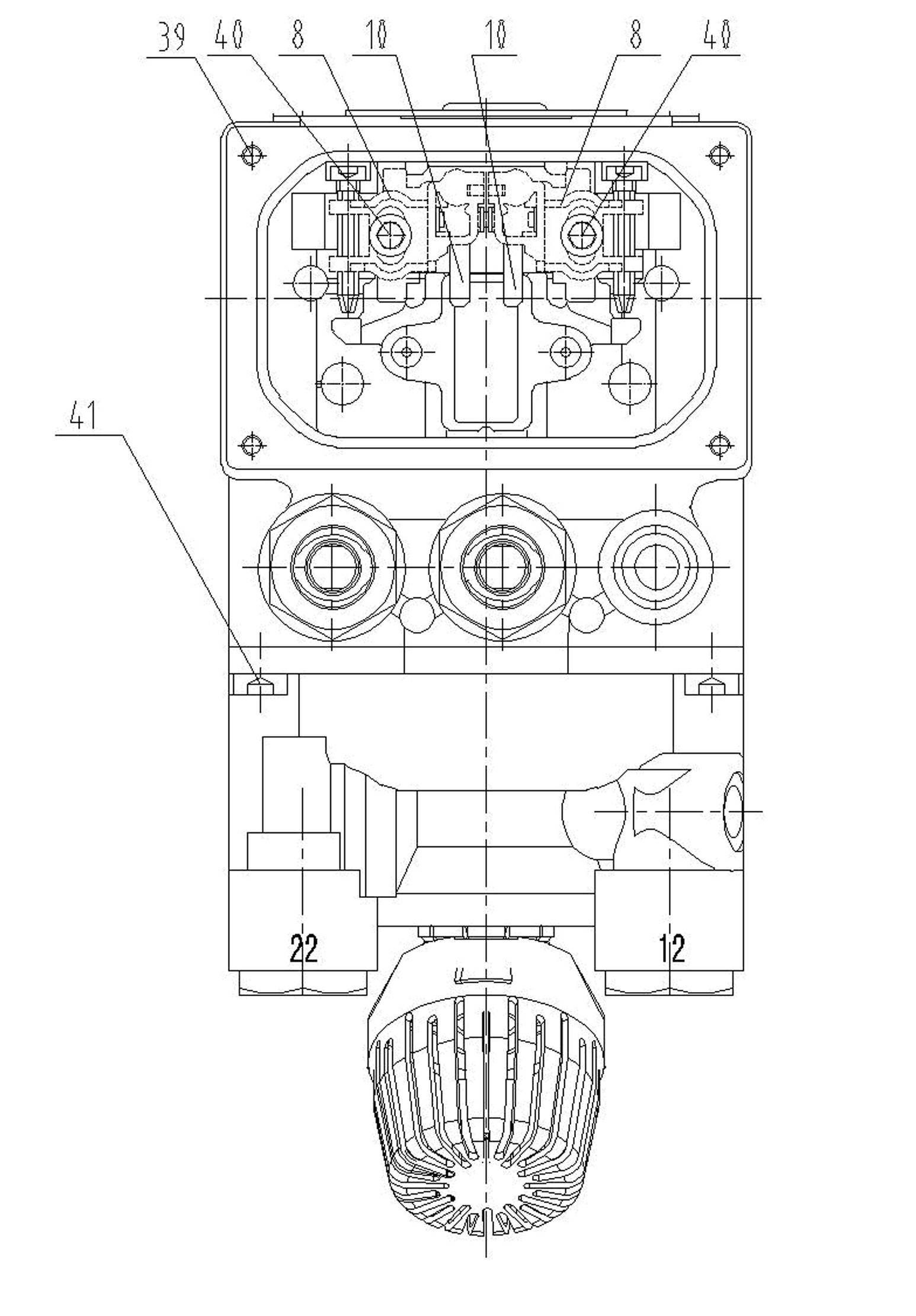

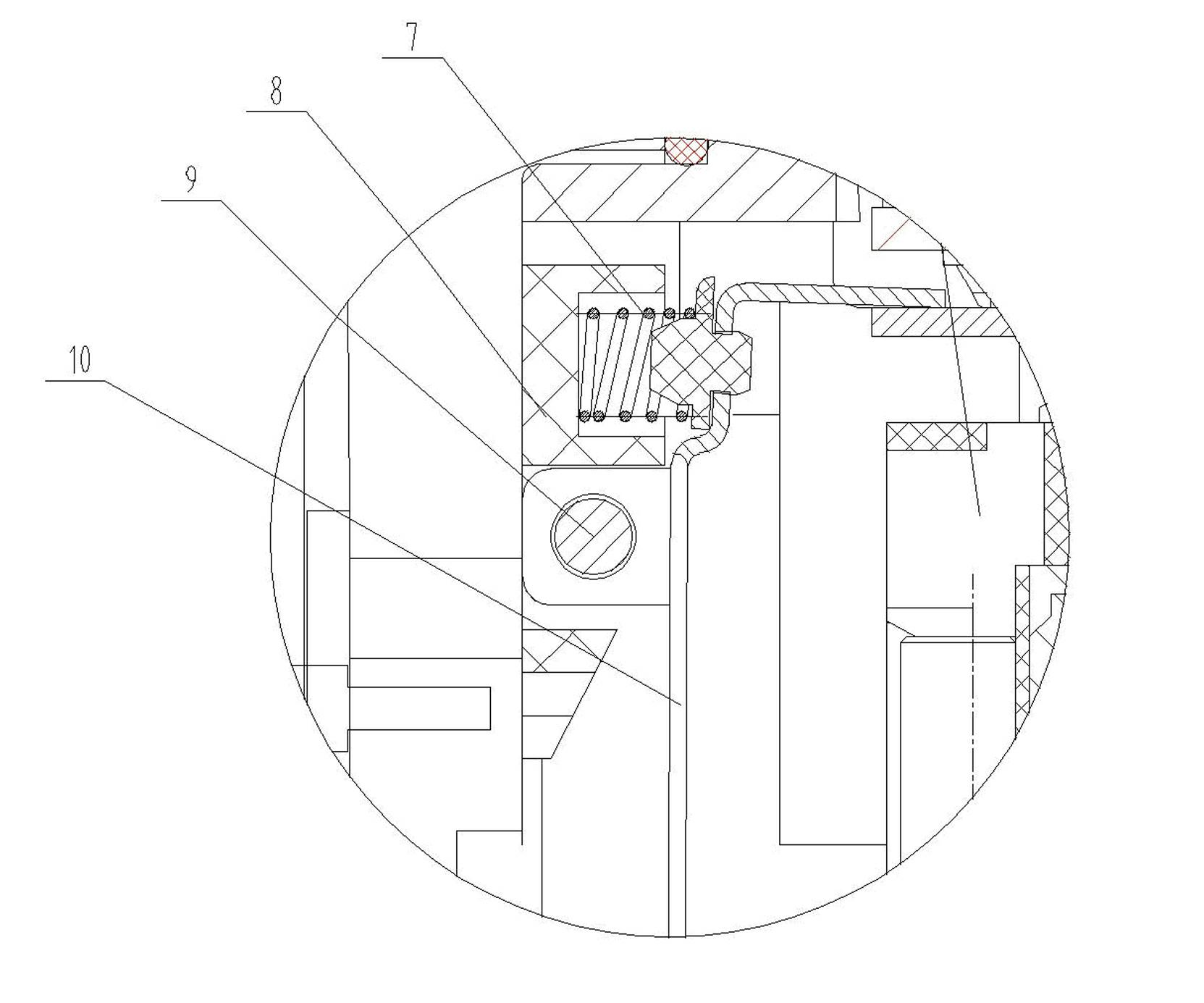

[0061] Such as Figure 1-4 As shown, the present invention relates to a brake master valve with electronic control double circuit and air control double circuit. Specifically, the assembly is mainly composed of an upper valve body 38, a lower valve body 26, and a plug seat 12. 38. The lower valve body 26 is connected with the bolt 41, and the plug seat 12 is connected with the upper valve body 26 through the bolt 39; the ejector seat 2 of the main brake valve is connected with the brake pedal through the ejector rod 3; : the upper piston 1, the ejector seat 2, the balance spring 4, the upper valve 33, etc.; the baffle 5 and the ejector seat 2 are fixed together by riveting or welding; the electromagnetic core seat 6 is fixed on the outer ring of the upper piston 1, The electromagnetic core 11 is fixed on the electromagnetic core seat 6, the middle piston 18 and the balance spring 4 are placed in the upper piston 1; a filter plug 34 is also arranged on the upper valve body, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com