Automatic wire arranging device of wire cutting machine and automatic wire arranging method thereof

An automatic wire arrangement and wire cutting machine technology, applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of waste wire staying in the wire tube, need to push the waste wire and insufficient air force, so as to achieve positioning good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

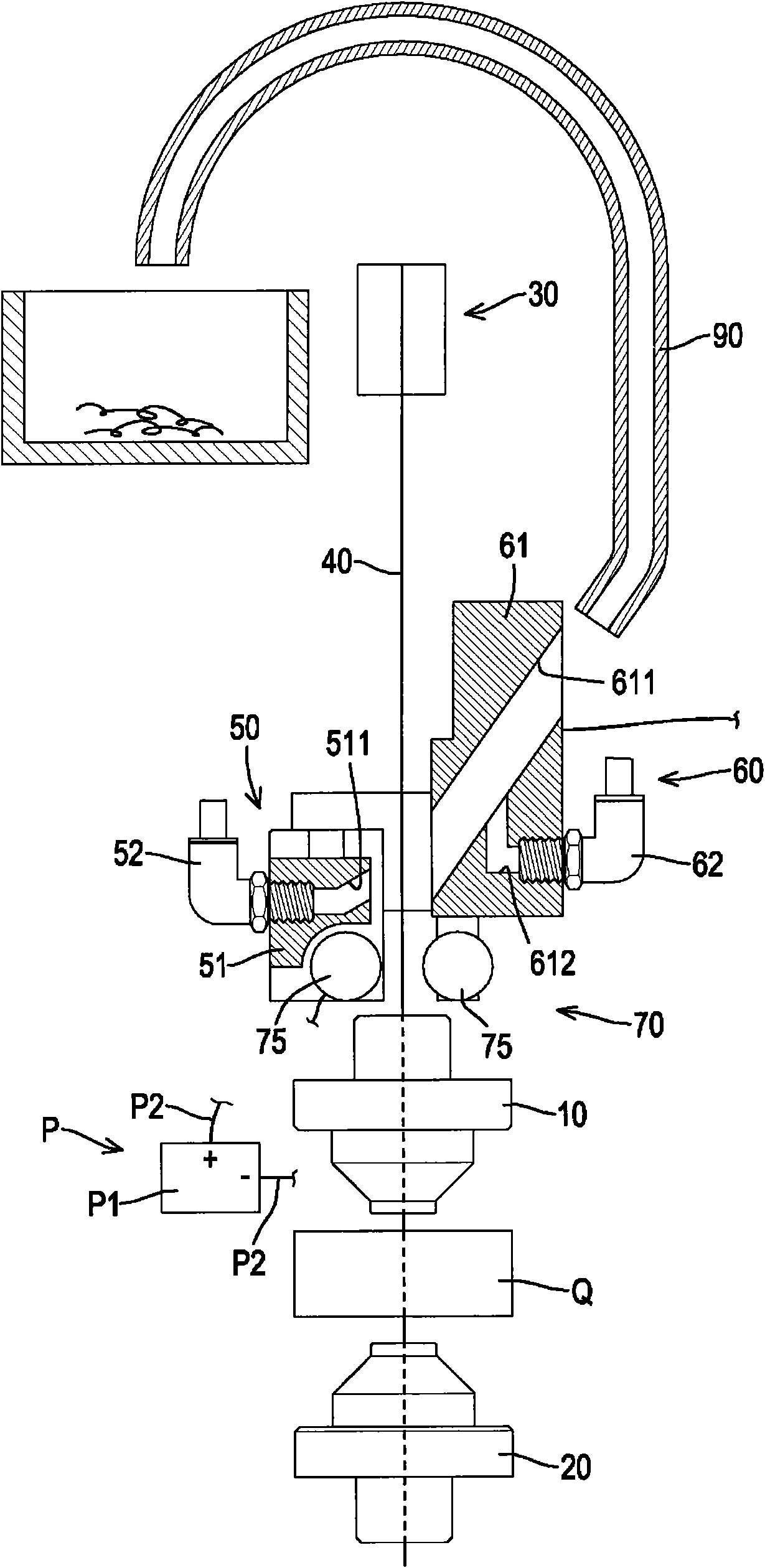

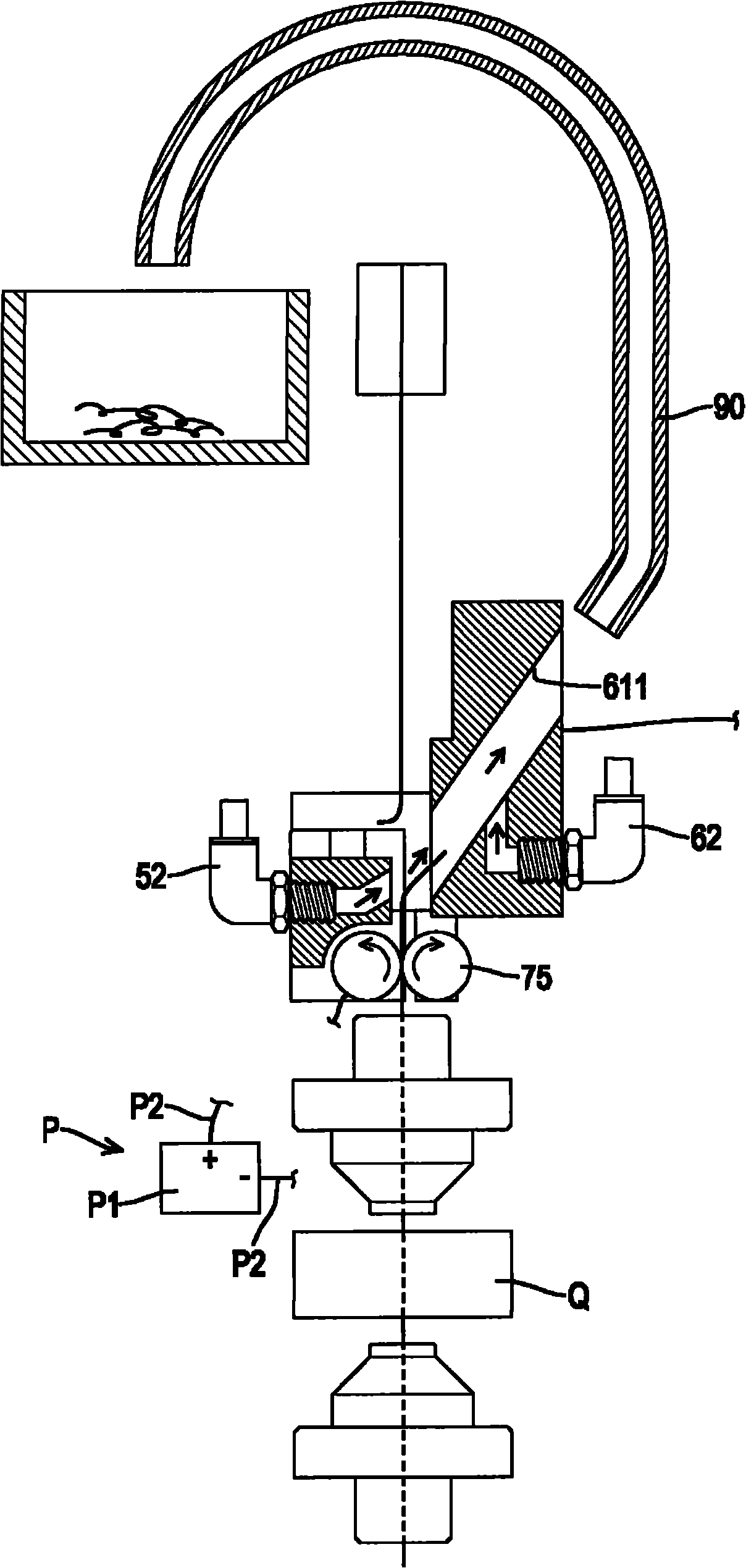

[0077] In order to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the description, the preferred embodiment shown in the accompanying drawings will be described in detail as follows:

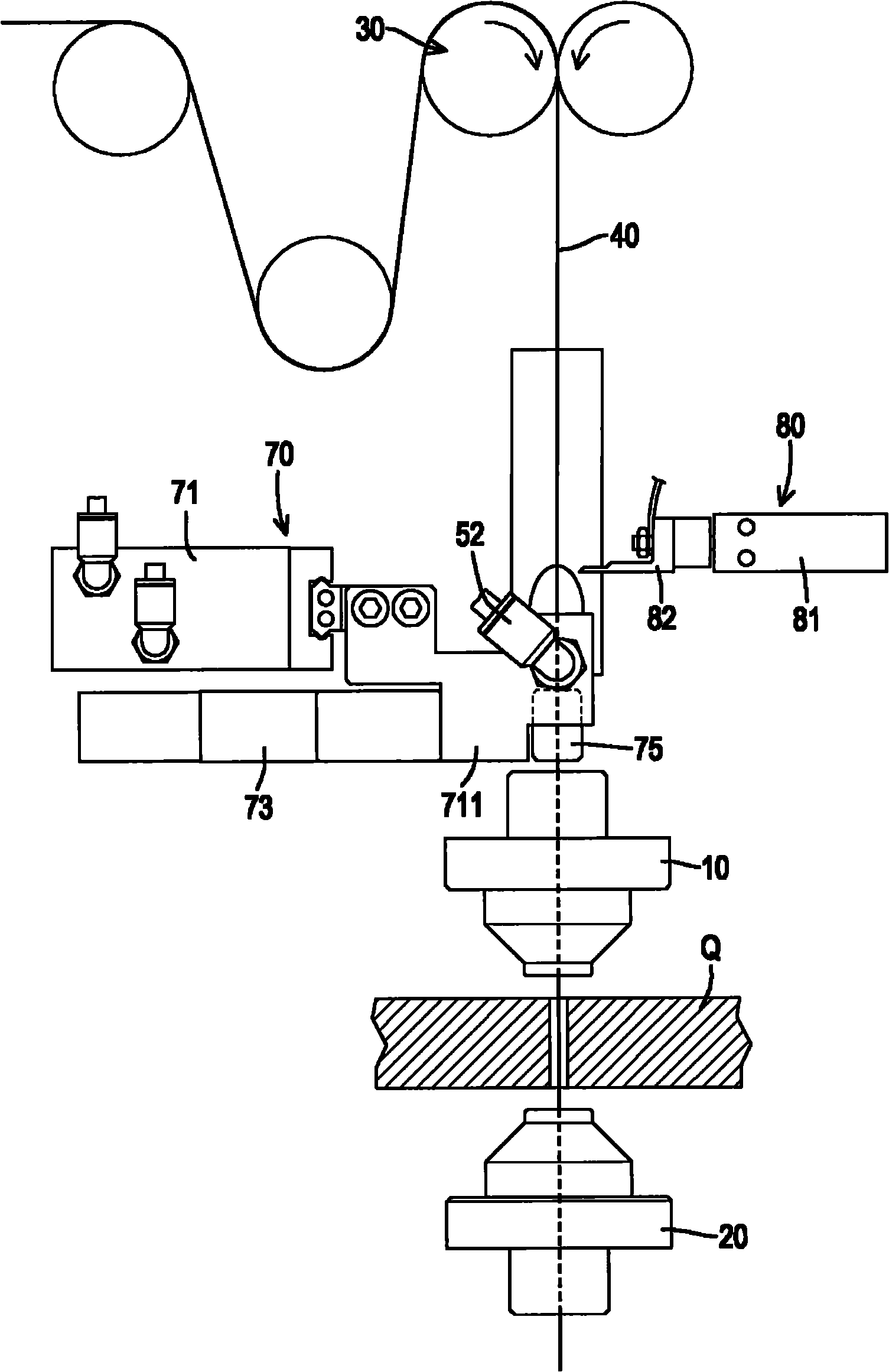

[0078] A preferred embodiment of the automatic wire arrangement device of a wire cutting machine provided by the present invention is installed on the wire cutting machine, such as figure 1 , figure 2 As shown, the wire cutting machine includes an upper positioning device 10, a lower positioning device 20, a wire outlet unit 30 and a wire body 40, wherein the wire body 40 is provided with a front side, a rear side, a left side and a On the right side, a metal workpiece Q is located between the upper positioning device 10 and the lower positioning device 20; the wire cutting machine belongs to the prior art, so its detailed structure and configuration relationship will not be repeated.

[0079] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com