Liquid fertilization mechanism

A liquid and liquid fertilizer technology, applied in direct liquid fertilizer conveying systems, agricultural gas emission reduction, etc., can solve the problems of large inertial force and low operation efficiency, and achieve the effects of small vibration, high operation efficiency and stable operation of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

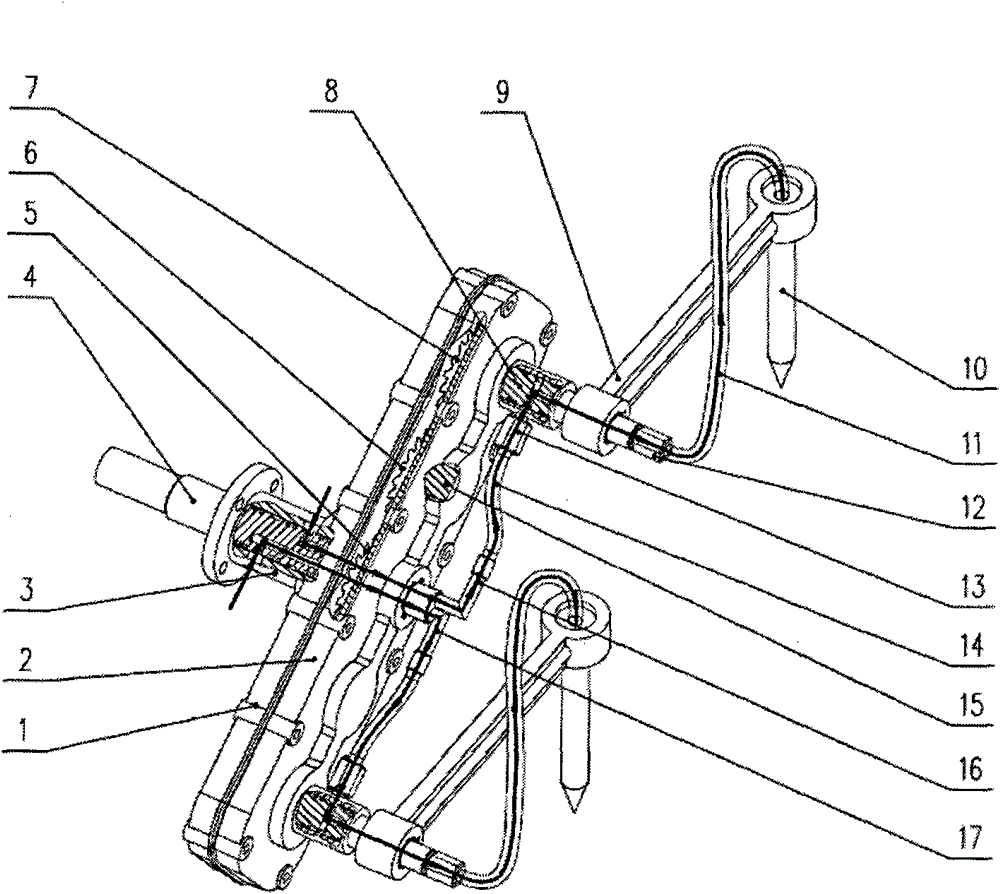

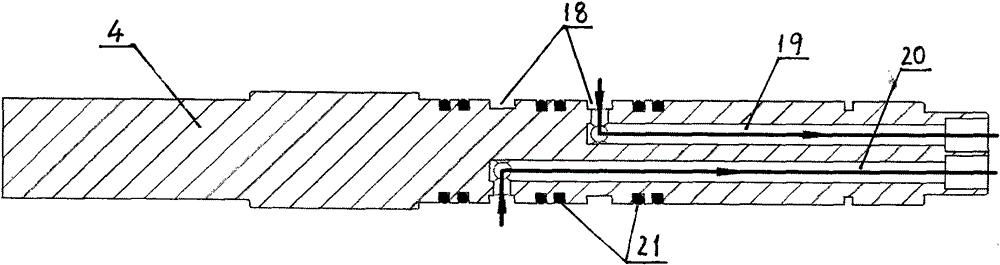

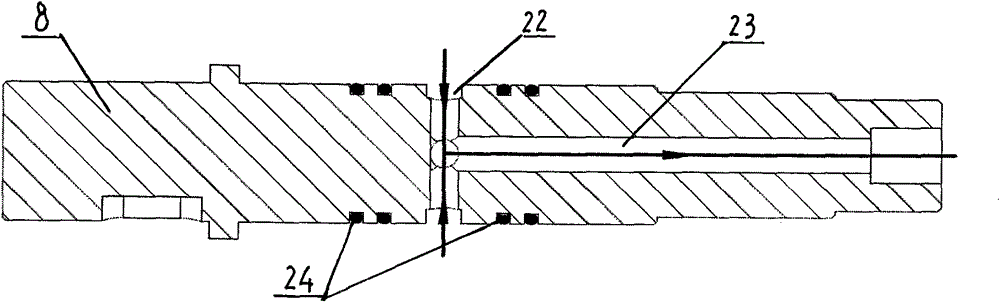

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A liquid fertilization mechanism, the right casing 2 is fixedly fitted on the right side of the left casing 1, and the left casing 1 and the right casing 2 form a gear box; Install the box frame 3 with two liquid fertilizer input holes, the sun gear shaft 4 is inserted on the box frame 3, the left casing 1 and the right casing 2, and the sun gear shaft 4 rotates and fits on the box frame 3, The sun gear shaft 4 is fixedly matched with the left housing 1 and the right housing 2, the sun gear 5 is rotatably set on the sun gear shaft 4, and the sun gear 5 is fixedly connected with the box frame 3; The sun gear 5 is equipped with an idler gear shaft 15 and a planetary gear shaft 8 respectively parallel to the sun gear shaft 4 on both sides symmetrically, the idler gear 6 is fixed on the idler gear shaft 15, and the planetary gear 7 is fixed Fitted on the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com