Centrifugal self-priming pump

A self-priming pump and centrifugal technology, applied in the field of centrifugal pumps, can solve the problems of prolonged self-priming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

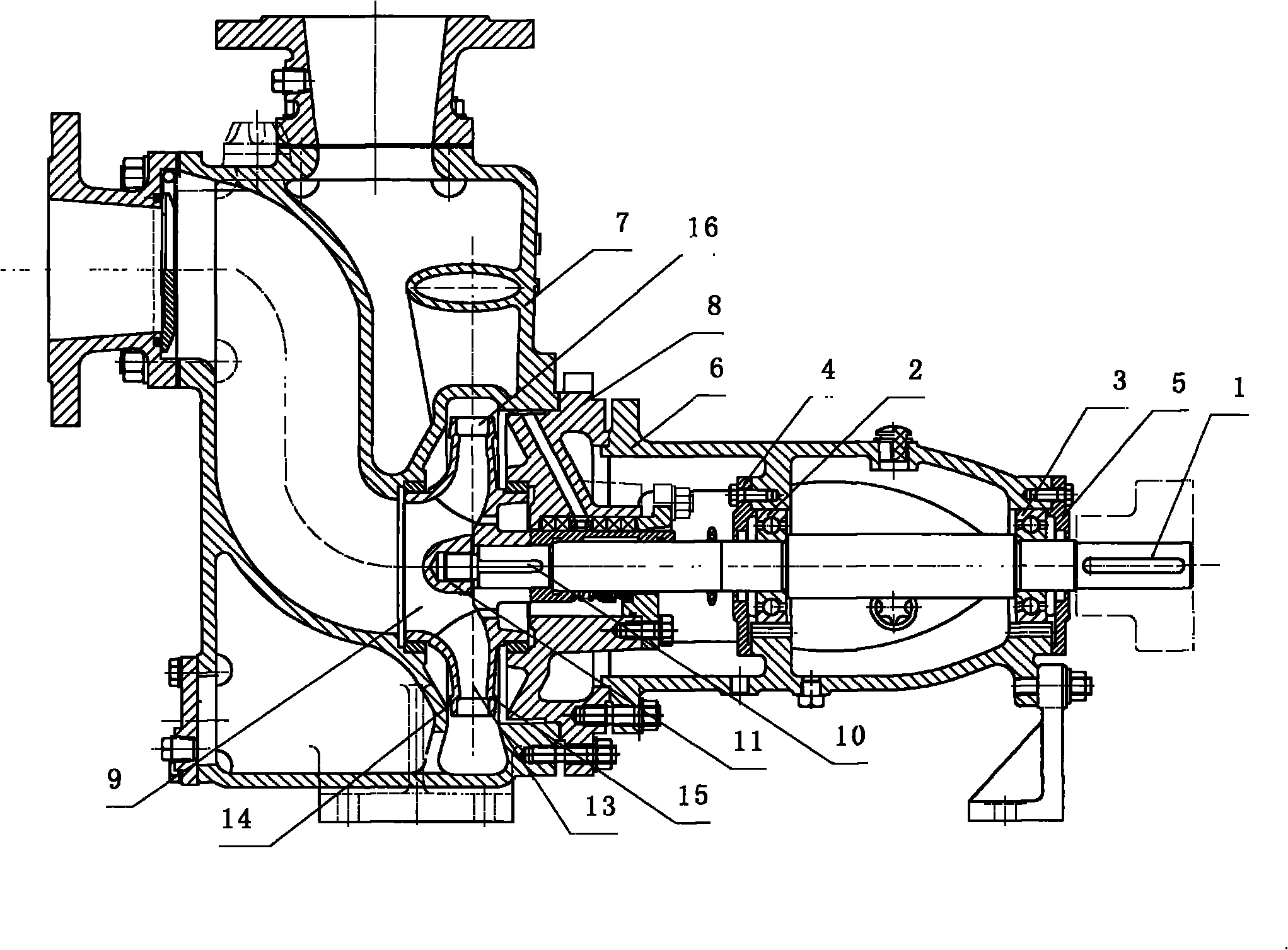

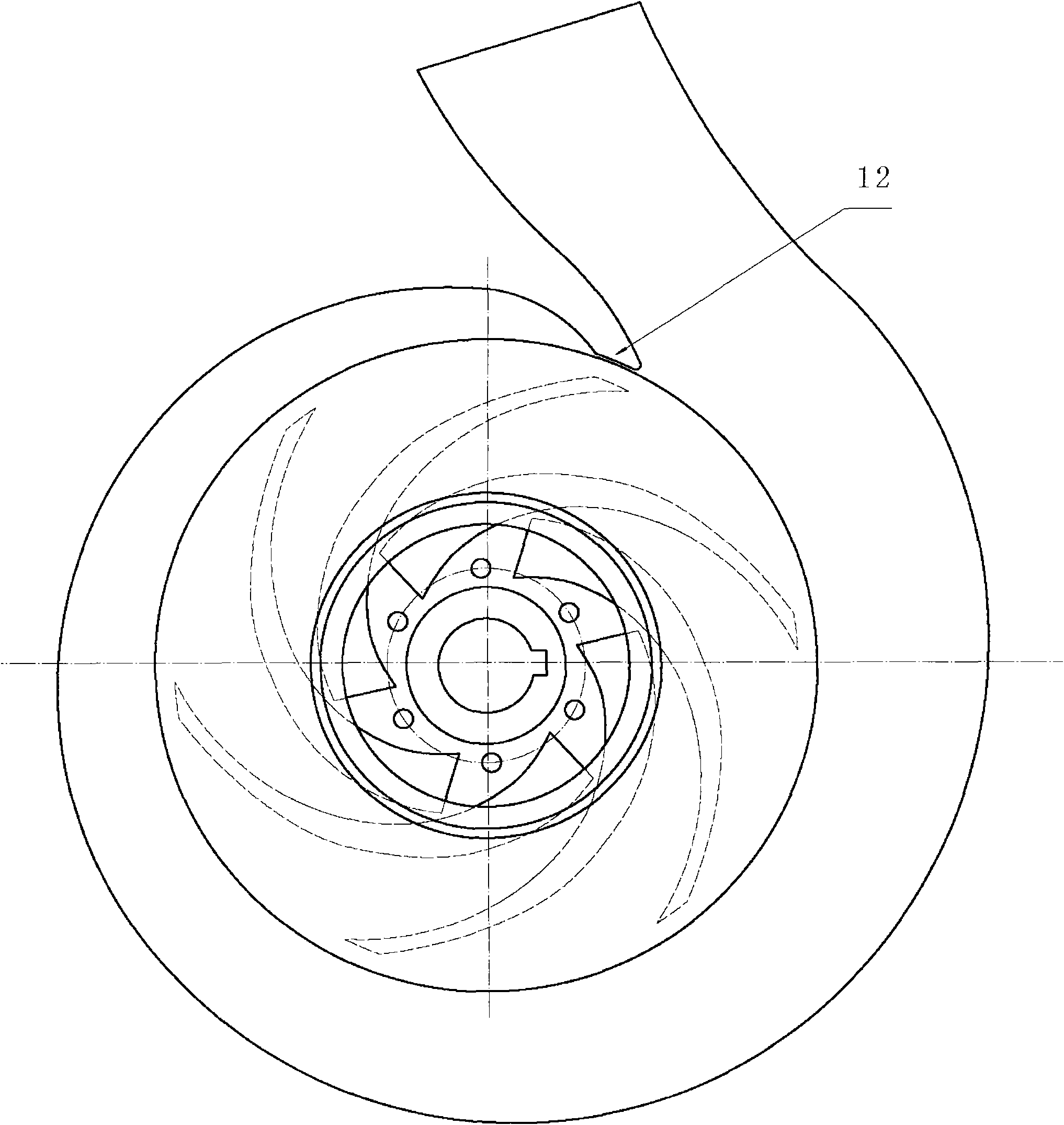

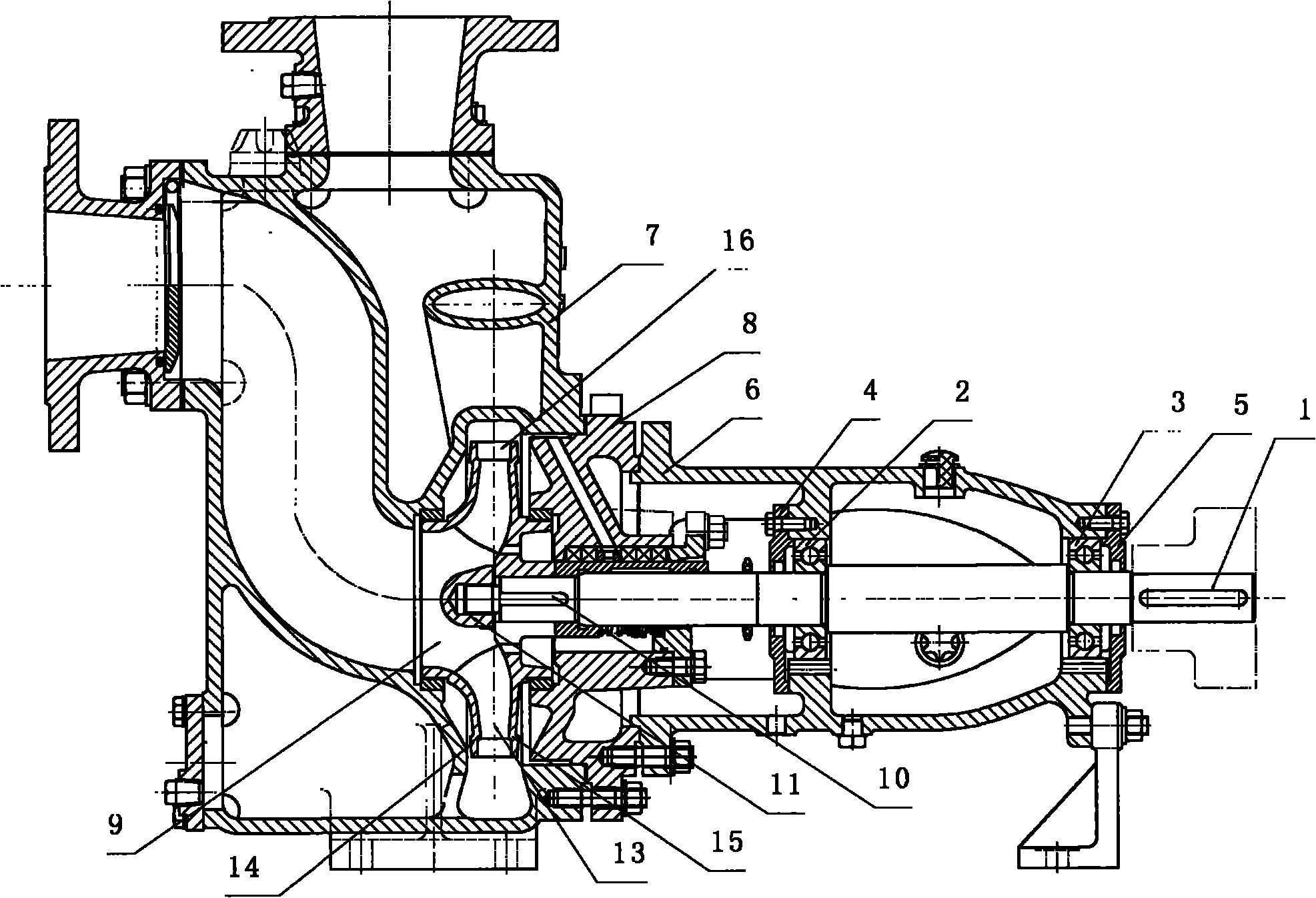

[0017] In this embodiment, the main shaft 1 is assembled on the suspension 6 through the front bearing 2, the rear bearing 3, the front bearing cover 4, and the rear bearing cover 5; the pump body 7 is assembled on the suspension 6 through the pump cover 8; The flat key 10 and the impeller nut 11 are assembled on the main shaft 1 in the pump body. The pump body 7 is provided with a specially designed partition tongue 12, the arc length of the partition tongue 12 parallel to the outer diameter of the impeller blade 13 is equal to 1.6 to 2.0 times the outer diameter arc length of the impeller blade; when it is necessary to change the pump flow rate, lift and When matching power, only the outer diameter of the pump impeller blade 13 is cut according to the design requirements, and the outer diameter of the front cover 14 and rear cover 15 of the pump impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com