Vertical hydraulic bracket

A technology of vertical hydraulic support and hydraulic support, which is applied in mine roof supports, mining equipment, earthwork drilling and mining, etc., and can solve problems such as low coal recovery rate, danger, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

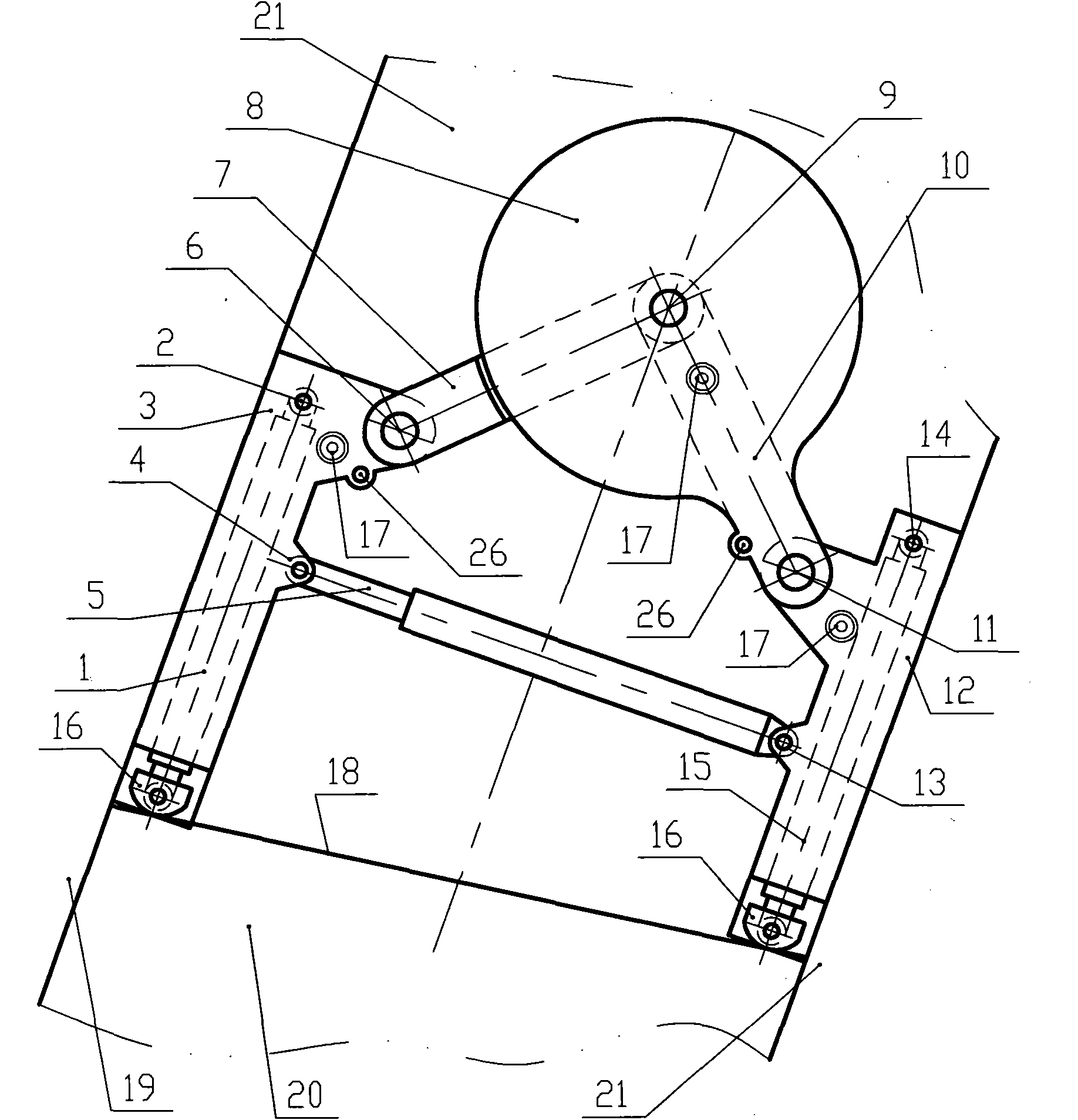

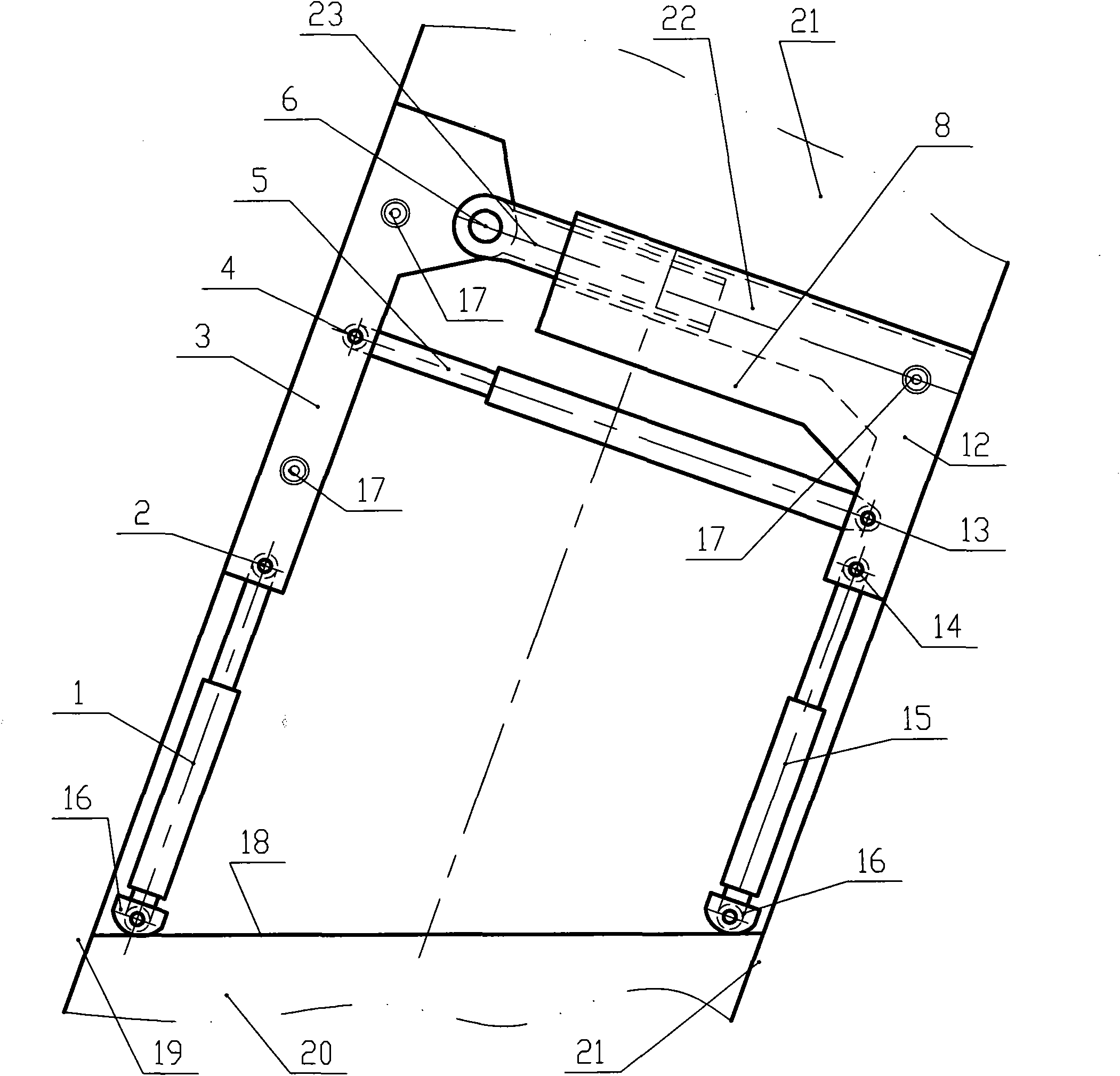

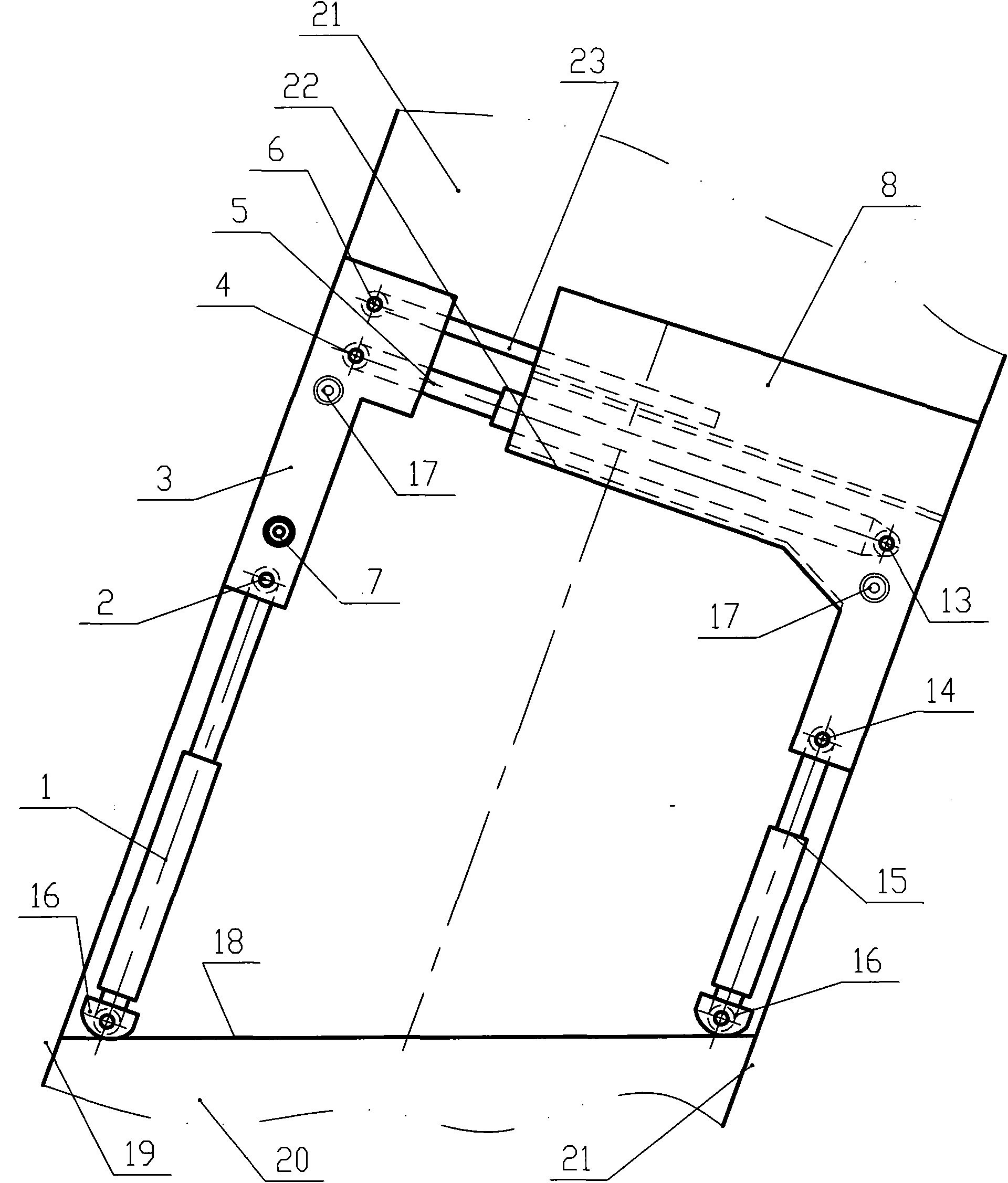

[0021] figure 1 A front view of the first embodiment of a vertical hydraulic support of the present invention is given. It includes roof beam 3, bottom beam 12, upper folded beam 7, lower folded beam 10, and not only includes roof support column 5 supporting the roof, but also supports wall columns supported on the coal wall. The top siding column 1 and the bottom siding column 15 close to the bottom plate. Among them, the upper end of the roof support wall column 1 is hinged with the top beam 3, and the lower end is supported on the coal wall 18. When the coal wall is soft or needs to be pulled down, the lower end is supported on the coal wall 18 through the column shoe 16 connected thereto; One end of the support column 5 is hinged to the top beam 3 through a hinge 4, and the other end is hinged to the bottom beam 12 through a hinge 13; It is hinged with the upper end of the lower folding beam 10, and the lower end of the lower folding beam 10 is hinged with the bottom bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com