a conveyor

A technology of conveyors and scraper conveyors, applied in the field of conveyors, can solve problems such as discarding, low coal recovery rate, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

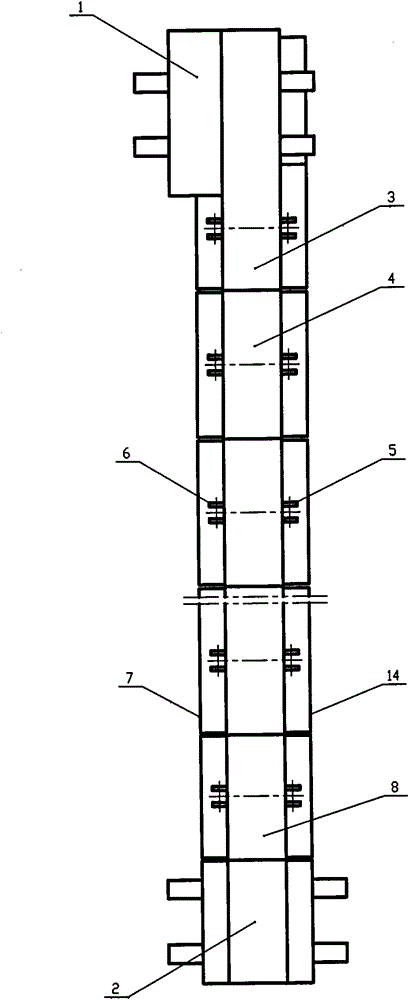

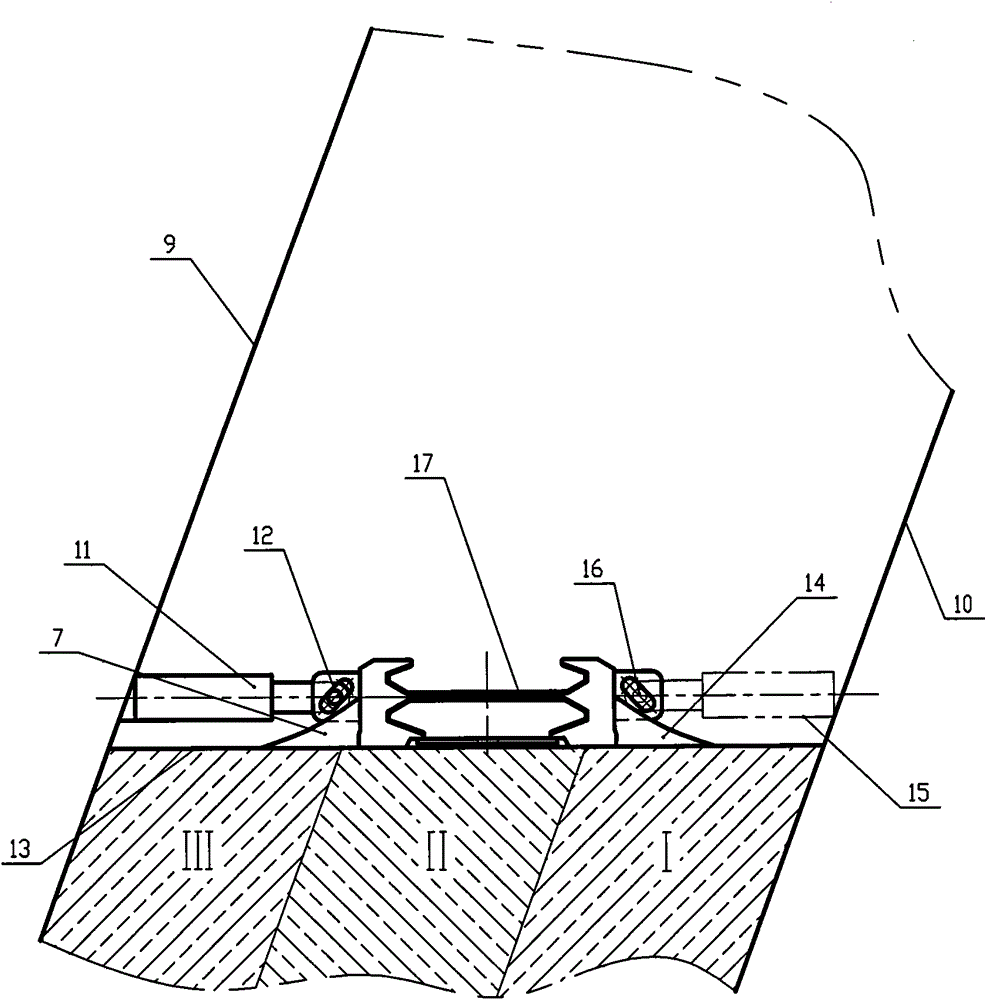

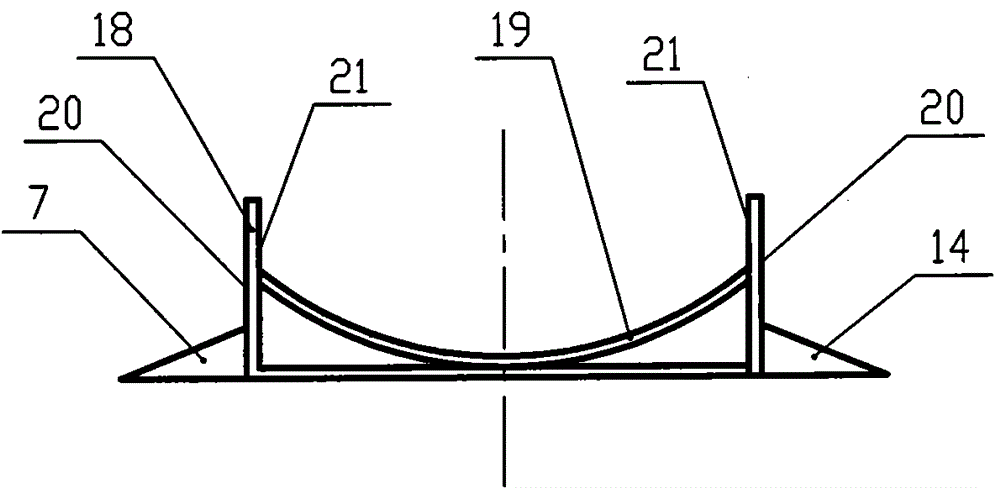

[0020] figure 1 A top view of a first embodiment of a conveyor of the present invention is given. Including machine head 1, machine tail 2, machine head transition slot 3, machine tail transition slot 8, middle slot 4, and also includes left coal shovel plate 7, right coal shovel plate 14, two-way push-pull lug plate 5 and / or 6 . The left shoveling coal plate 7 and the right shoveling coal plate 14 are respectively arranged on the both sides of the conveyor, so as to reach the purpose of two-way pushing away and two-way shoveling coal. figure 2 The vertical seam coal mining working face layout diagram of the first embodiment of a conveyor of the present invention is given. In the vertical seam coal mining working face, the mining direction is along the top and bottom plates to the coal wall direction, and the conveyor The direction of propulsion has been changed from advancing along the bottom plate to the direction of the coal wall to advancing along the coal wall to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com