Method for building sea filling embankment

A sea embankment and embankment technology, which is applied in the field of urban road embankment engineering construction, can solve the problems of slow construction progress, large working area, and difficulty in meeting the construction progress, so as to reduce the amount of silt engineering, shorten the construction time, project cost and economic benefits obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

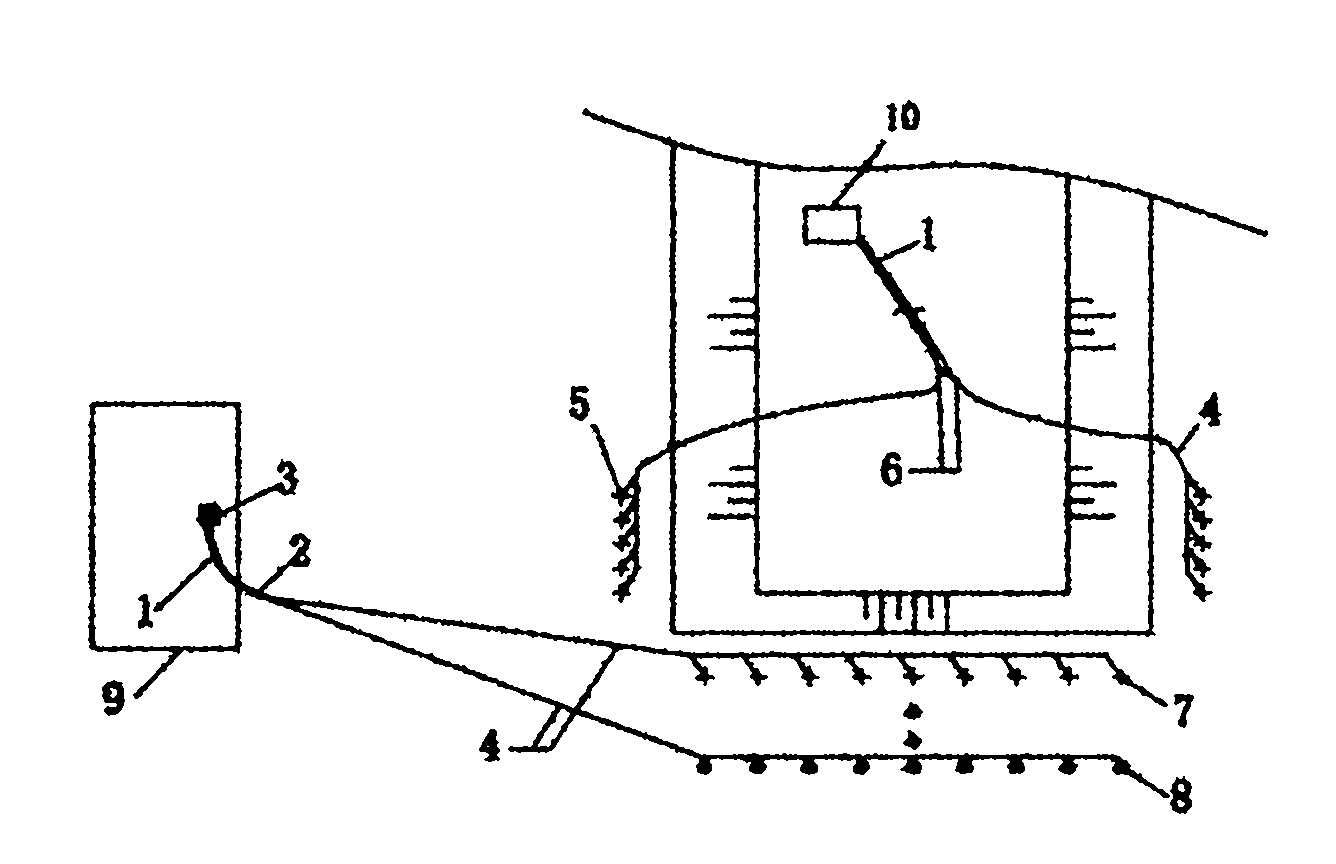

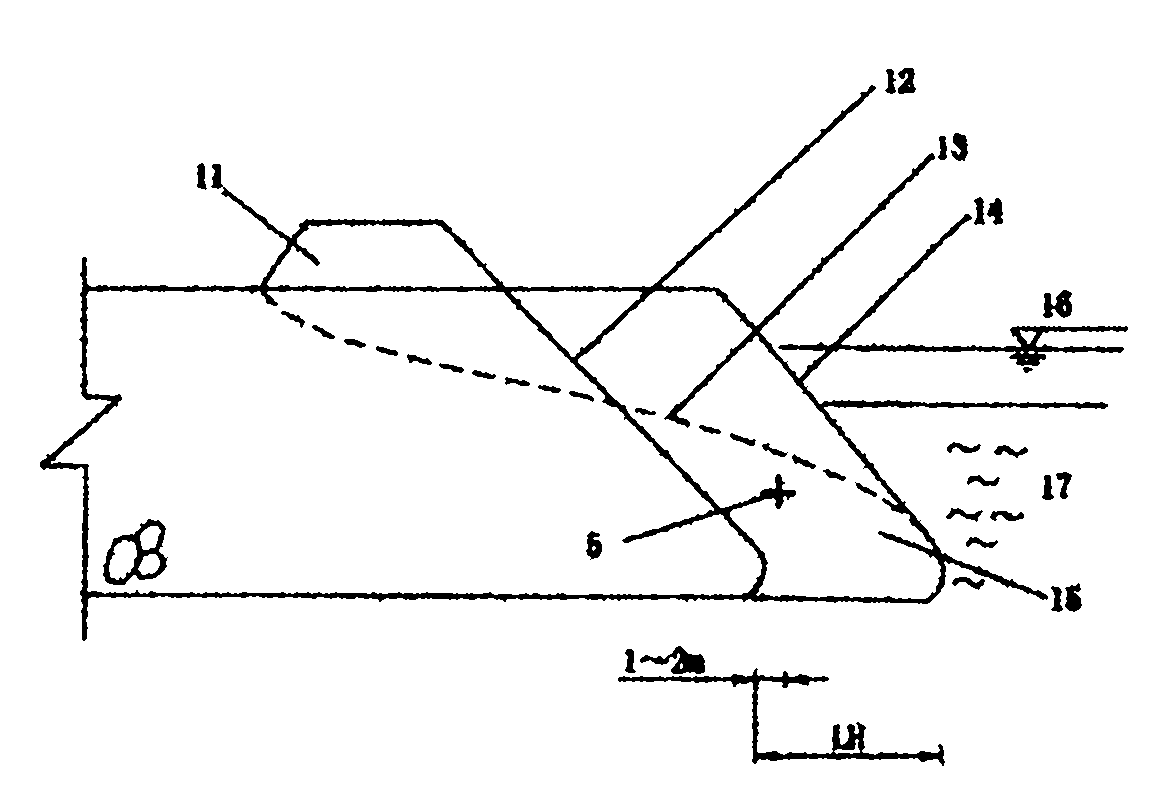

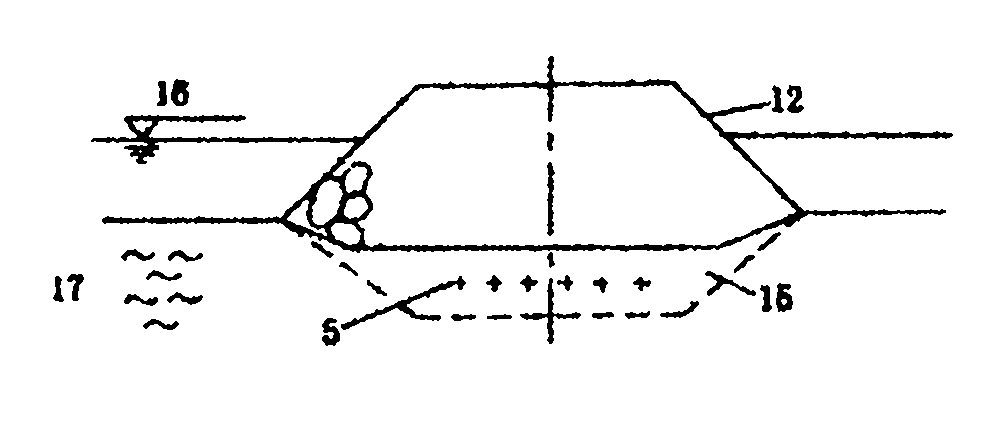

[0078] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1-5 Shown, a kind of construction method of reclamation embankment comprises the following steps:

[0079] A. Select bearing layer: According to geological data, load and use requirements, apply embankment stability and settlement calculation results to select bearing layer;

[0080] B. Select embankment section: Use embankment stability calculation and slope protection form to determine embankment section, especially for coastal embankment due to wave action, intertidal zone slope protection, underwater platform and wave load, rationally select slope protection form and embankment slope Foot outer platform width;

[0081] C. Determine throwing and filling parameters: The throwing and filling parameters include the height and width of embankment body throwing and filling. The design section of the dike body, the thickness of the silt 17 and its strength ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com