Fine-tuning construction method for CRTS I (China railway track system) type slab ballastless track

A technology of slab ballastless track and construction method, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of complicated procedures, prone to errors, increased transmission error, etc., and achieves strong process operability and fast adjustment speed. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

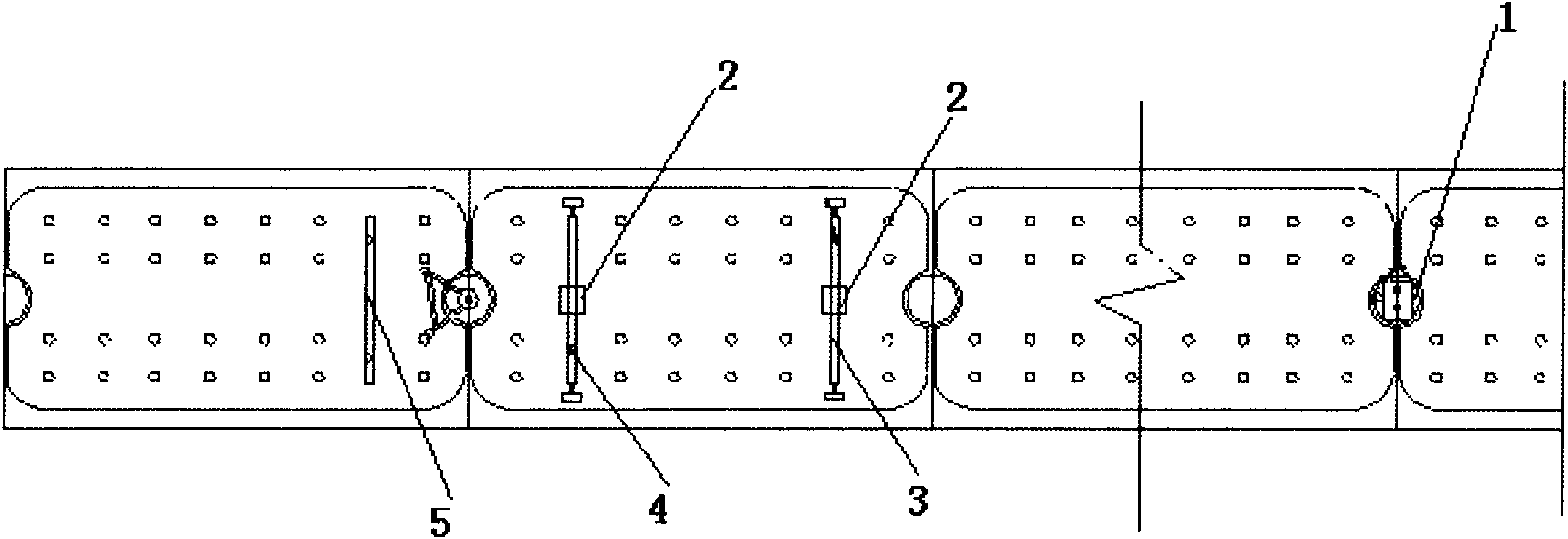

[0021] Referring to the accompanying drawings, the fine-tuning construction method of CRTS I-type slab ballastless track includes the following construction steps:

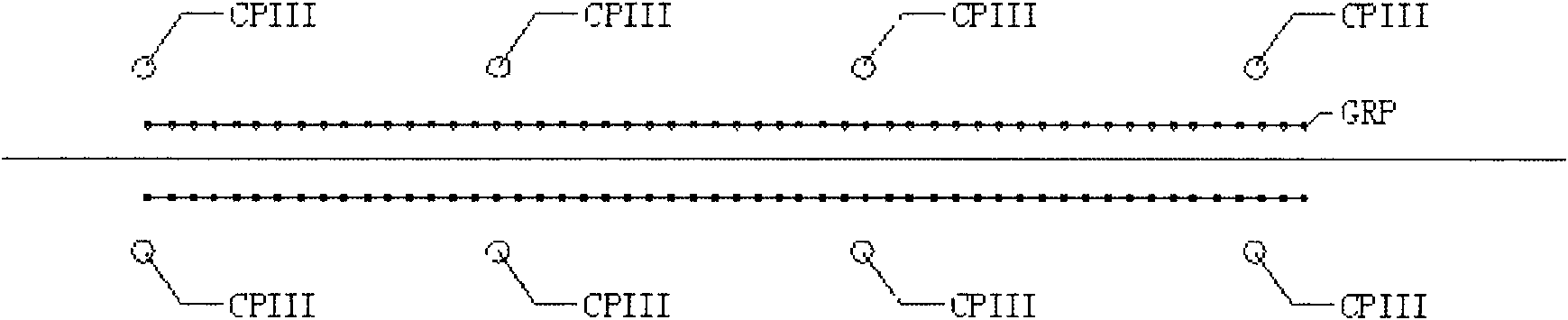

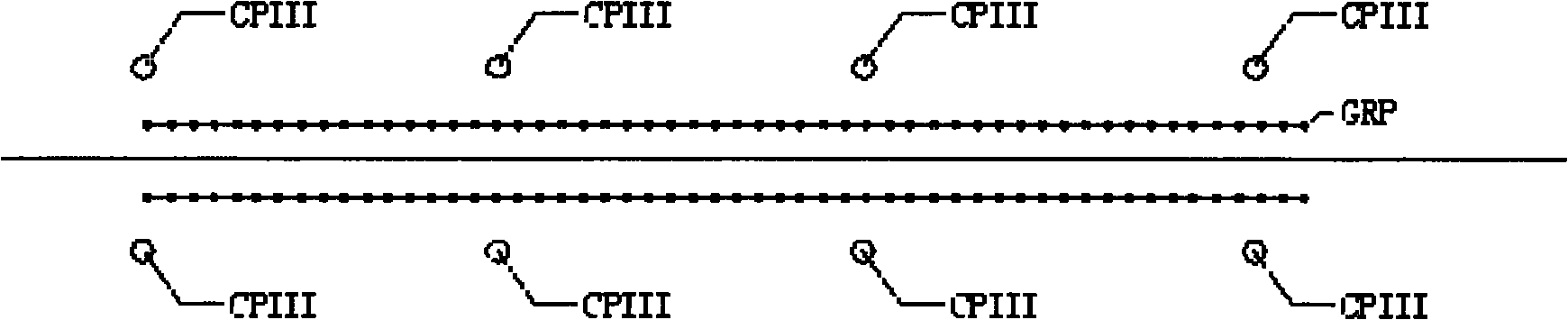

[0022] 1), the establishment and measurement of GRP

[0023] a. For the burial of GRP, use the design parameters of the corresponding railway line and the design mileage of GRP, use professional software to calculate the coordinate value of GRP, take the CPIII on both sides of the line as the rear view, and use the high-precision total station 1 to accurately stake out the GRP point, and bury GRP steel rods as required;

[0024] b. GRP three-dimensional coordinate measurement, the measurement of GRP plane coordinates is based on the CPIII on both sides of the line as the rear view, and the high-precision total station is used to measure the GRP plane coordinates according to the measurement plan. The height measurement of GRP uses a high-precision electronic level and a The supporting bar code leveling rod has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com