Die locking mechanism

A technology of mold clamping and mold clamping devices, which is applied in the field of mold clamping mechanisms, can solve problems such as the difficulty of fully hydraulic mold clamping mechanisms, the overall weight of the mold clamping parts, and the inconvenient transportation and hoisting, etc., and achieve low cost and guiding Reliable and rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Provide a best embodiment of the present invention below in conjunction with accompanying drawing.

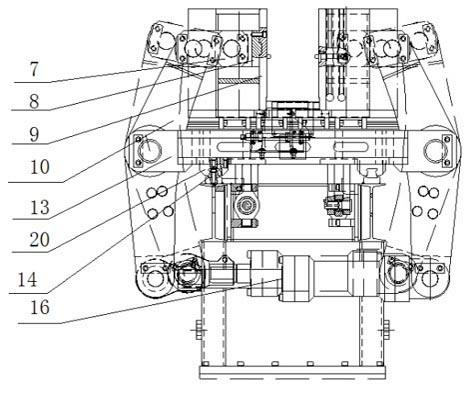

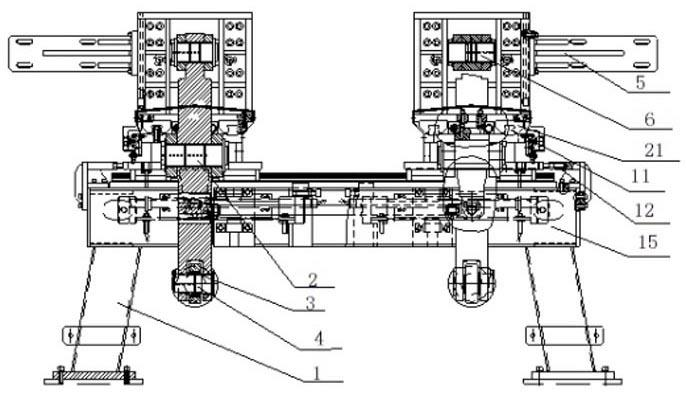

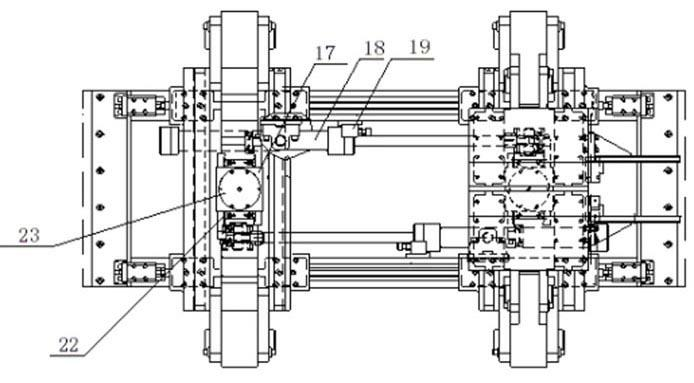

[0017] A clamping mechanism such as figure 1 , figure 2 , image 3 As shown, it includes a frame 1, on which an underframe 15 is installed, and the top of the underframe is provided with a two-column form-moving guide rail pair 14 horizontally, and each of the two ends of the form-moving guide rail pair is provided with a locking mold of the same structure. Device; the mold clamping device includes a crossbeam 13 perpendicular to the mold-moving guide rail, the bottom of the beam is provided with a mold-moving slider 20 to cooperate with the mold-moving guide rail, and the beam is provided with a two-column mold clamping perpendicular to the mold-moving guide rail The guide rail is 11, and the mold locking guide rail is provided with a pair of symmetrical hinge arm connecting seats 8, and the bottom of the hinge arm connecting seat is provided with a mold locking slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com