Planar module type equipment structure

A flat module and equipment technology, which is applied in the direction of surface pretreatment, devices for coating liquid on the surface, electrical components, etc., can solve problems such as affecting the working speed, etc., and achieve the effect of compact layout, simple and fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

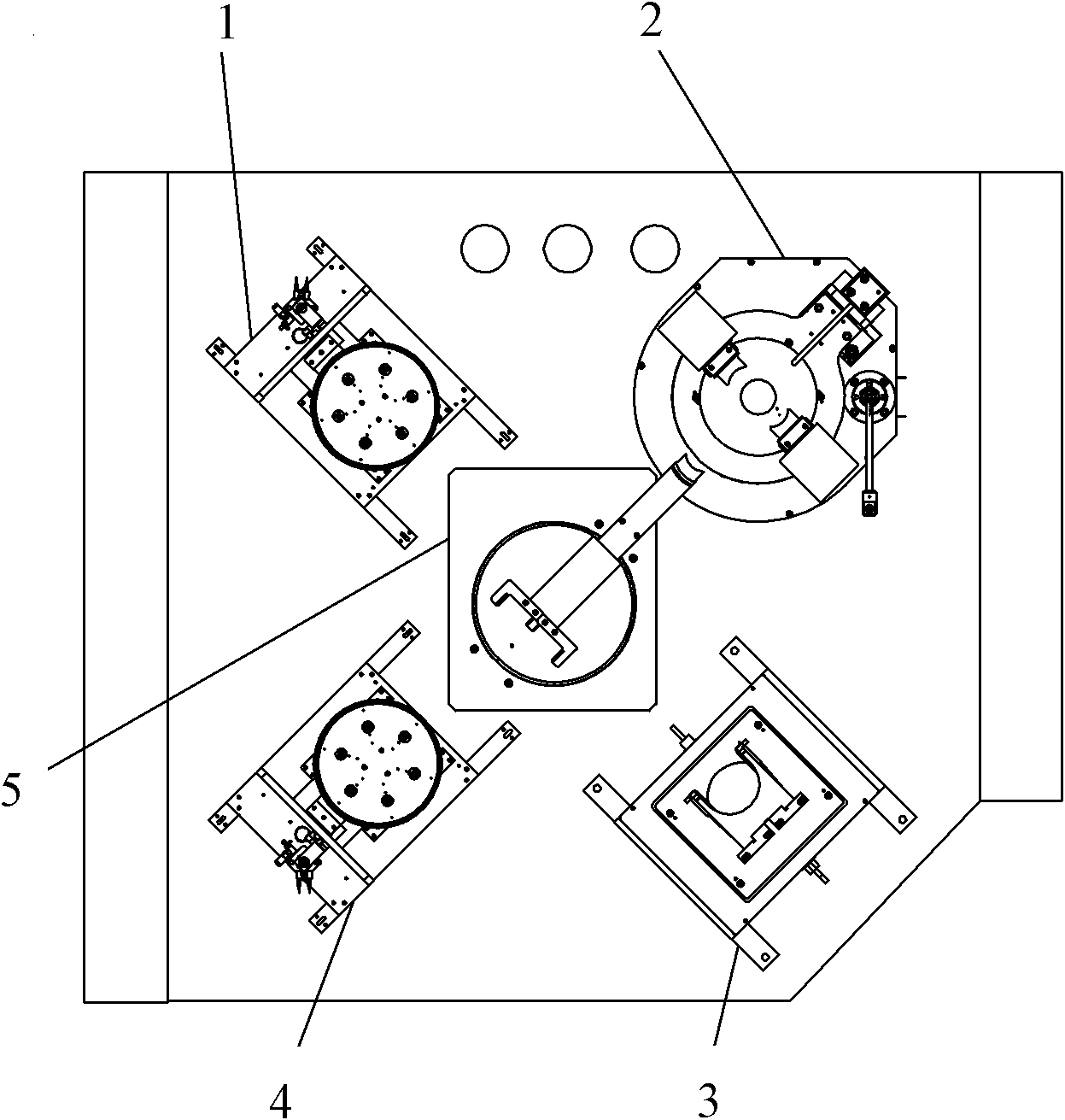

[0015] Such as Figure 1-Figure 2 As shown, the planar modular equipment structure of the present invention mainly includes: hot plate I 1, process module 2, film cassette 3, hot plate II 4, two-axis manipulator 5, slide table 6, base 7, etc., the specific structure is as follows:

[0016] Two-axis manipulator 5 is in the center, hot plate I 1, process module 2, film cassette 3, and heat plate II 4 are distributed around the two-axis manipulator 5, heat plate I 1, process module 2, film box 3, and heat plate II 4 1. The two-axis manipulator 5 is located on the same plane, and the two-axis manipulator 5 only has rotation and telescopic actions, without lifting. The transfer of wafers among the modules is realized by the scheduling of the two-axis manipulator 5 in the center.

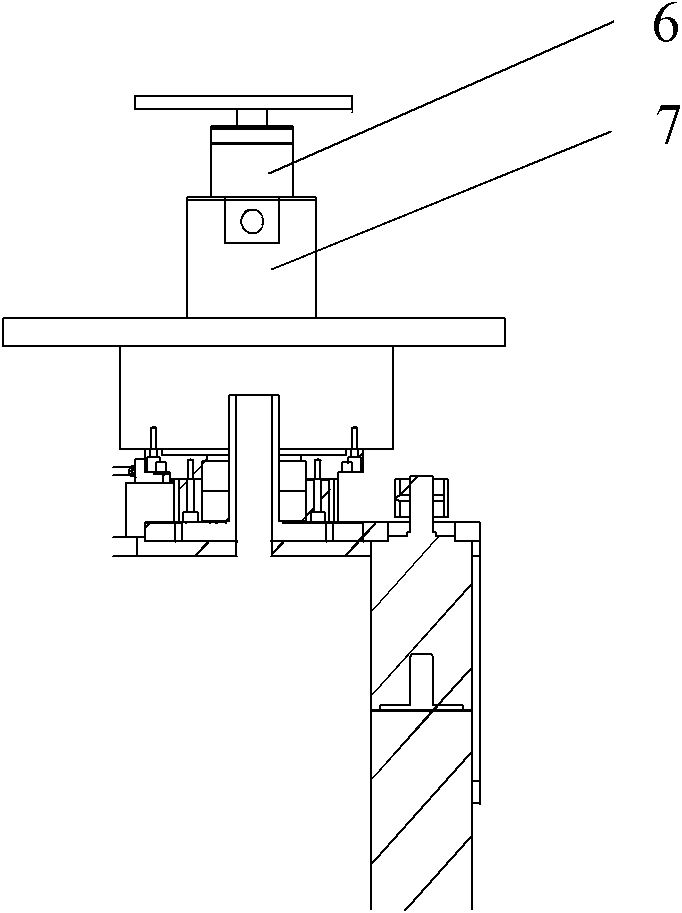

[0017] The telescopic part of the two-axis manipulator 5 is provided with a slide table 6 and a base 7, and the two-axis manipulator 5 is driven by the slide table 6 connected on the base 7 to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com