Method for detecting internal diameter size of extra-large bearing ferrule seam allowance

A bearing ring and extra-large technology, which is applied to the detection field of the inner diameter size of the super-large bearing ring, can solve the problems of undetectable pipe gauge clamping rod and low precision, and achieve a simple and practical detection method and accurate detection results. , the effect of simple structure and easy to do

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

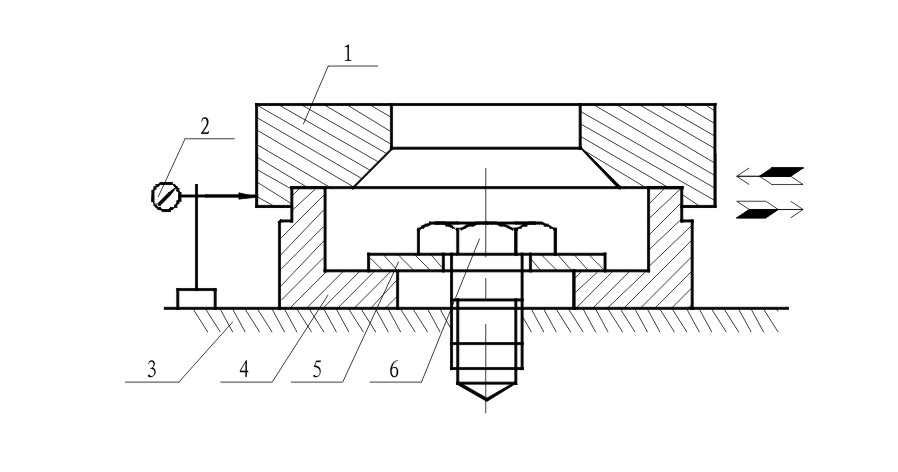

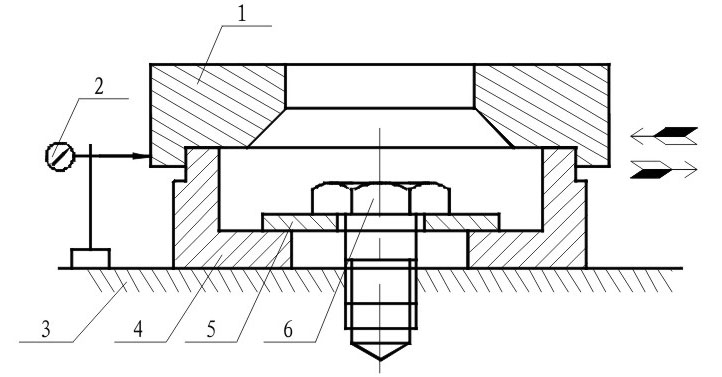

[0013] combine figure 1 , the present invention is a detection method for the inner diameter of the spigot of a super large bearing ring. Sleeve 4, the upper end of the positioning sleeve 4 is a convex ring, the depth of the convex ring is 5mm greater than the depth of the ring 1 stop 3mm, and the nominal diameter of the convex ring is 500mm equal to the ring 1 stop The nominal diameter of the inner diameter is 500mm. The bottom end of the positioning sleeve 4 has a central inner hole for its fixing. The positioning sleeve 4 is fixed on the measuring platform 3 by using the bottom plane of the positioning sleeve 4 as the positioning surface and the bolt 6 and the pressure plate 5. The bottom plane of the positioning sleeve 4 needs to be finished, which can not only improve the detection accuracy of the present invention, but also make the detection method of the present invention simple and easy, and greatly improve the detection efficiency.

[0014] Take the outer diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com