Two-stage oil absorption electric fuel pump with jet

An electric fuel pump and jet technology, applied in the direction of pumps, pump devices, engine components, etc., can solve the problems of increasing the difficulty and complexity of processing the pump body, reducing the effective output power of the motor, and the large load of the oil pump motor, so as to reduce the processing difficulty. and complexity, reducing load, and increasing traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

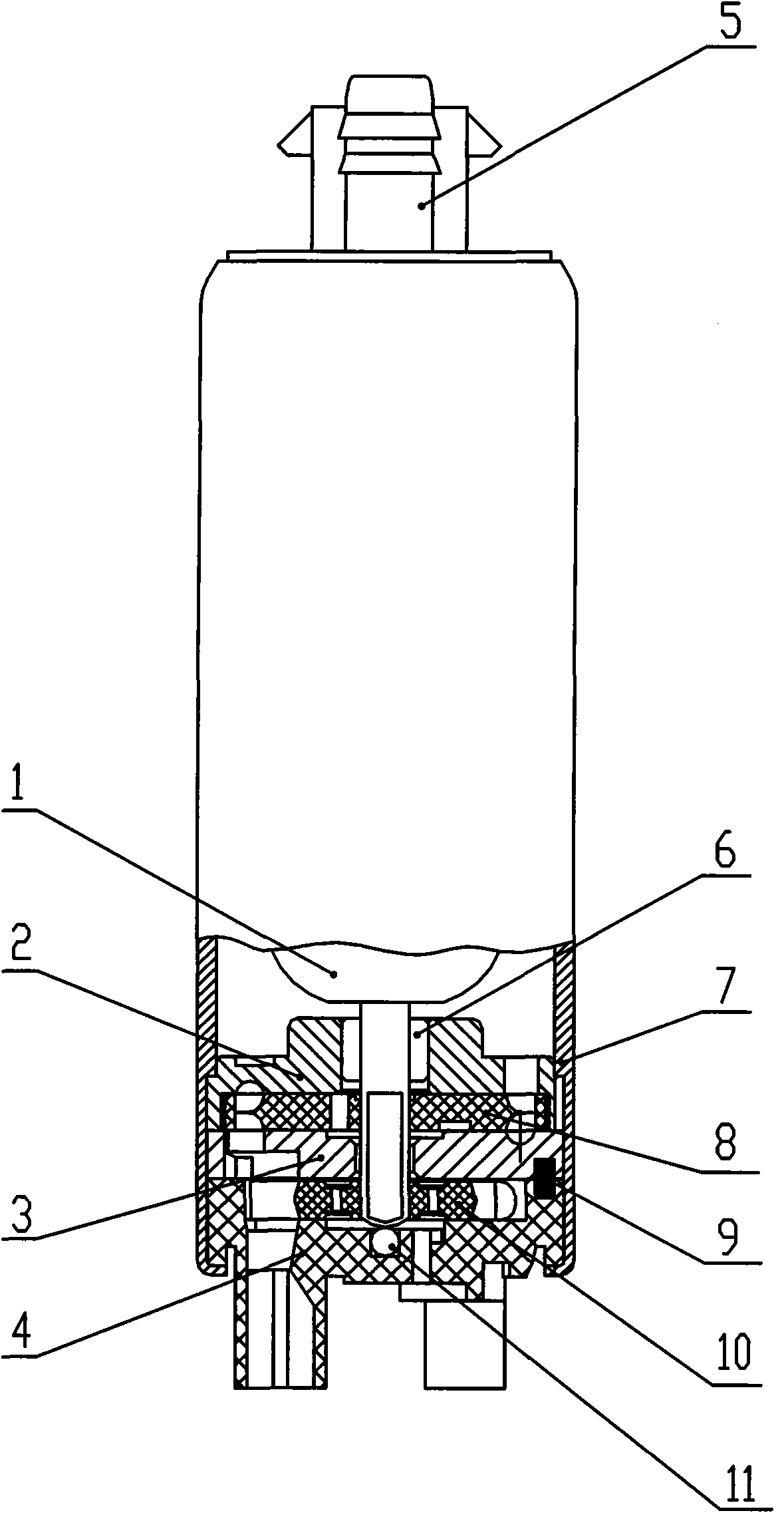

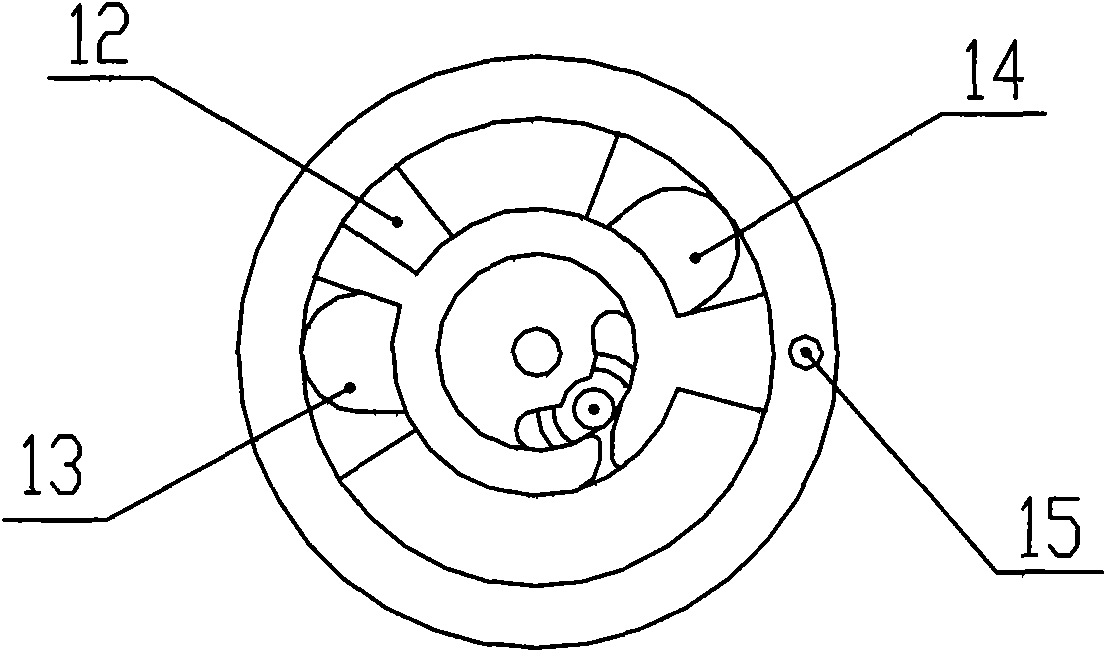

[0013] Such as Figure 1 to Figure 3 As shown, the two-stage oil-suction electric fuel pump with jet flow of the present invention includes a motor 1, a pump body and a casing 7, the motor 1 and the pump body are installed in the casing 7, and the pump body includes an oil outlet plate 2, a secondary impeller 8, an oil inlet Plate 3, primary impeller 10 and pump cover 4, oil outlet plate 2 is installed on motor 1 through oil bearing 6; both ends of secondary impeller 8 matched with motor 1 are respectively matched with oil outlet plate 2 and oil inlet plate 3 , that is, the second-stage impeller 8 is located between the oil outlet plate 2 and the oil inlet plate 3, the motor 1 cooperates with the first-stage impeller 10, and finally the motor 1 pushes to the steel ball 11, and the two ends of the first-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com