Salt mine double-well solution mining method

A mining method and well water technology, which are applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of downhole crystallization blocking pipes, threatening the safe production of wells, blockage, etc., so as to reduce the cost of well workover, The effect of reducing well workover times and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

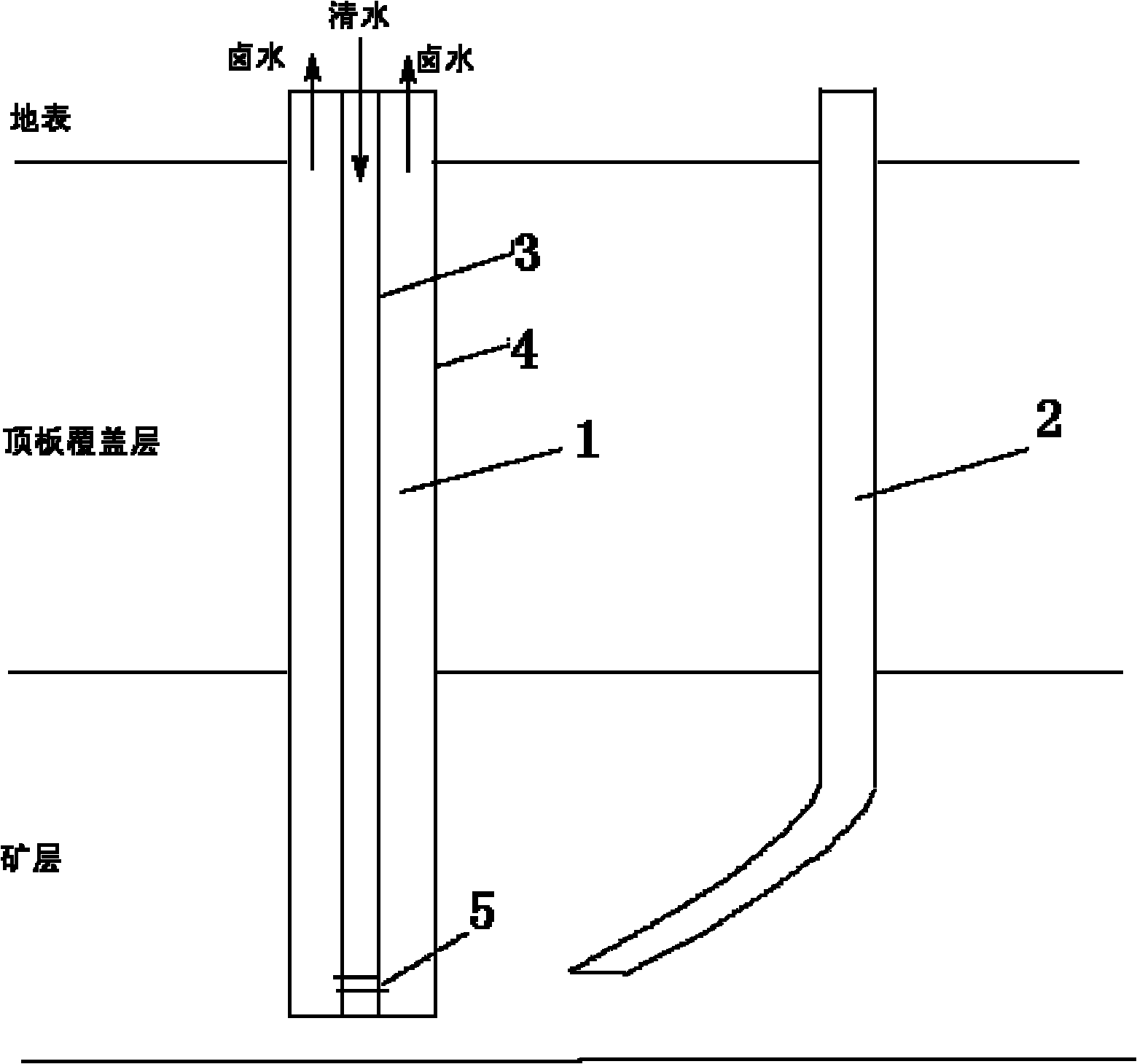

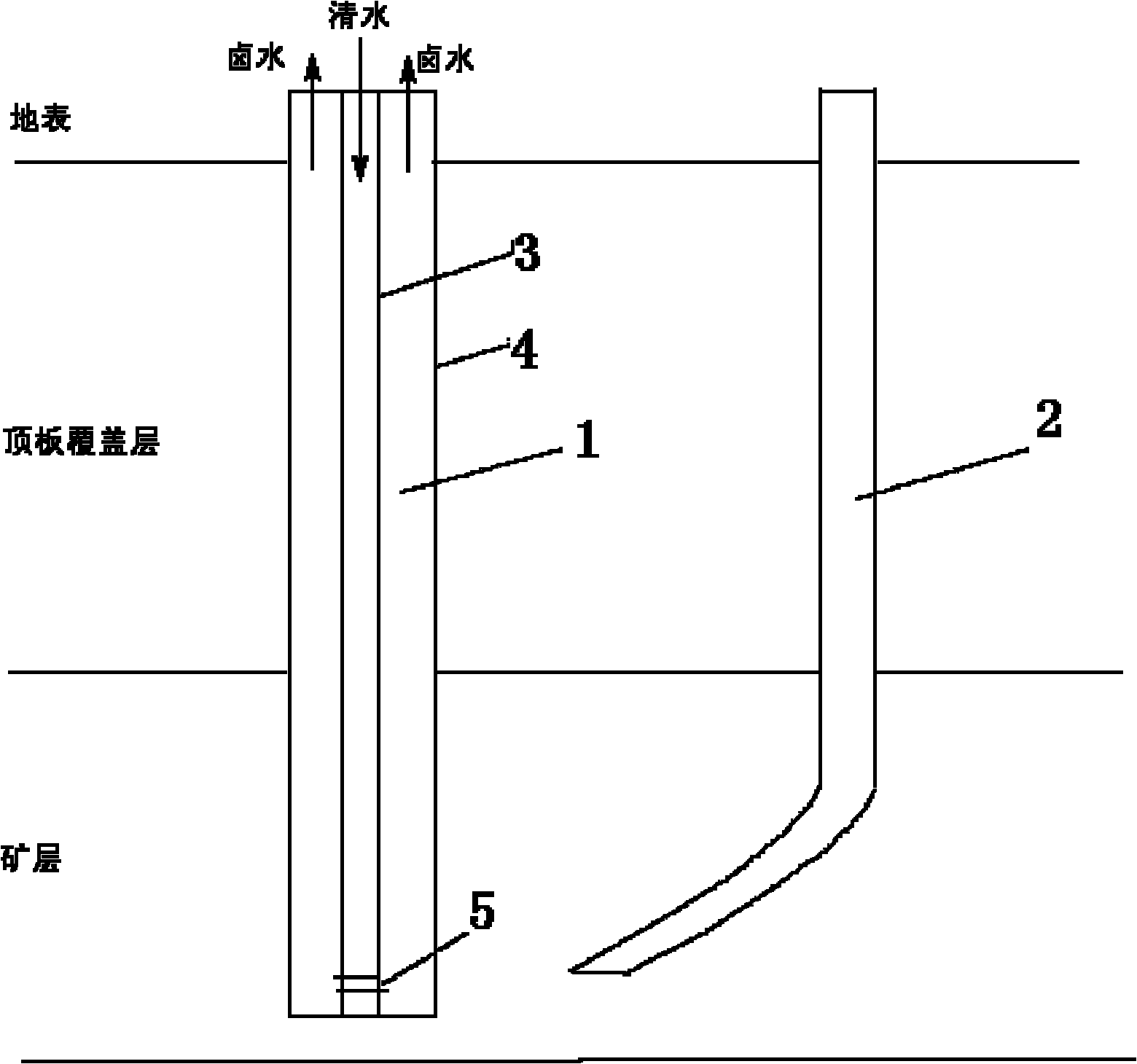

[0007] The present invention will be further described below in conjunction with accompanying drawing:

[0008] Such as figure 1 As shown, in the present invention, perforations 5 are opened on both sides of the bottom of the center pipe 3 of the vertical well 1. During the production process of the well, when clear water is injected into the horizontal well 2, a part of the clear water is injected into the center pipe 3 of the vertical well, so that the clear water is injected into the center pipe 3 of the vertical well. The vertical well center pipe perforation 5 flows into the casing 4, dilutes the supersaturated brine in the vertical well casing 4, monitors the water injection flow rate of the vertical well center pipe through the electromagnetic flowmeter display, and accurately controls the brine concentration of the vertical well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com