Synchrotron radiation curve-edge focus lens design method by combining gravity bending coordinating and maximum application range

A technology with scope of application and design method, applied in the fields of synchrotron radiation beamline engineering and synchrotron radiation optics, it can solve the problems of not well eliminating the gravitational surface error and residual surface error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

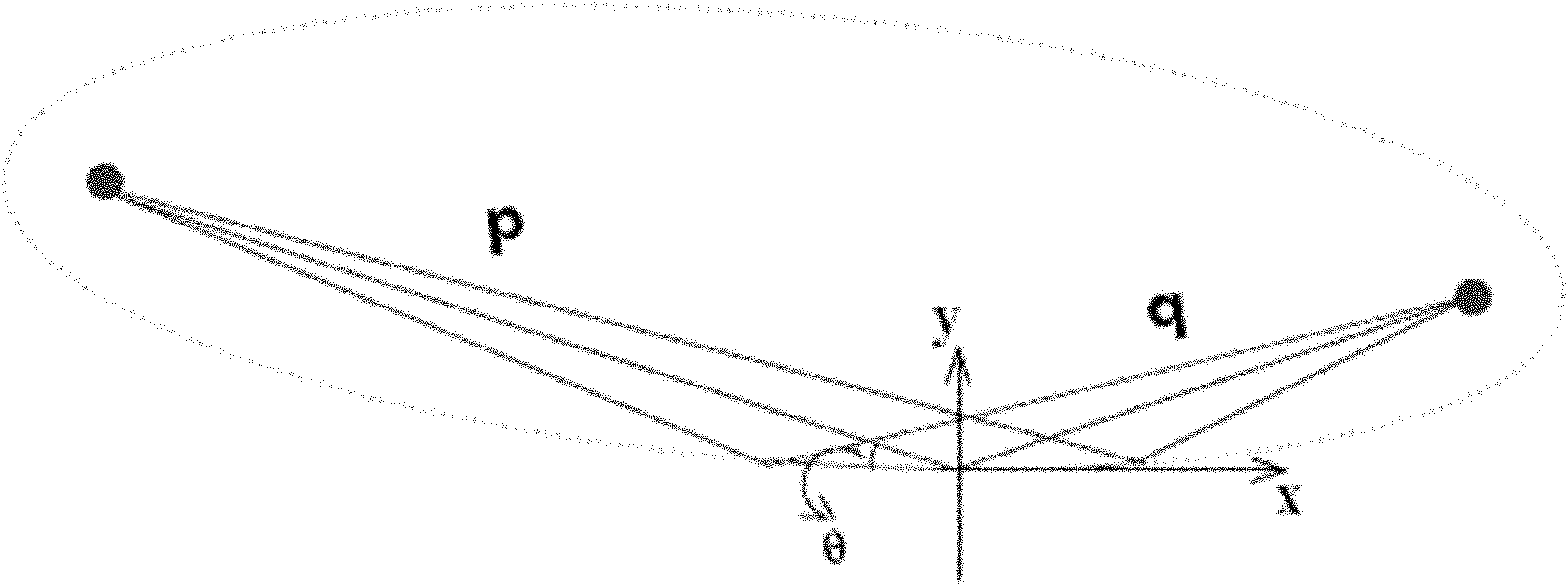

[0061] In the present invention, the design idea of gravity-coordinated bending is not to use gravity as a system error source, but to incorporate it as a part of the bending force into the design of the bending surface together with the bending force applied at both ends, and design accordingly The geometric parameters and bending mechanical parameters of the mirror body, thereby eliminating the gravity surface shape error. The design idea of maximizing the applicable range is to minimize the absolute value of the derivative of the root mean square of the total remaining surface shape error with respect to the focus condition at the design value, that is, the rise is the slowest near the design position as the focus condition changes, so that the Focusing mirrors maximize the range of application for a certain focusing condition....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com