Arbitrarily triangular sensor and calibration method thereof

A calibration method and sensor technology, which is applied in the field of sensors and their calibration, can solve problems such as unreasonable structure and difficult installation of sensors, and achieve the effects of eliminating scratches, reducing installation and debugging requirements, and increasing the size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

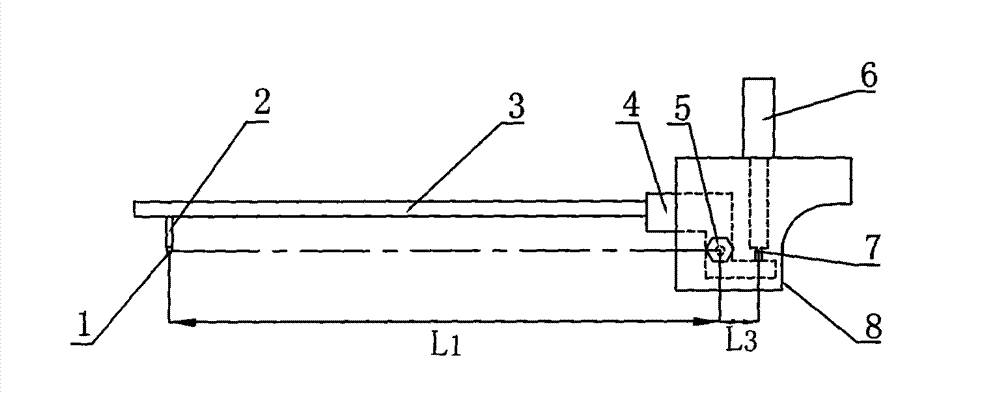

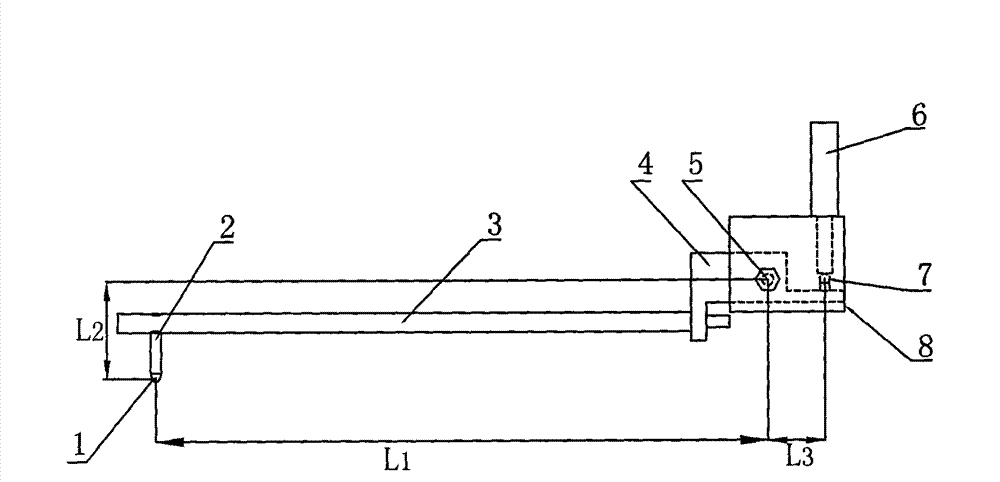

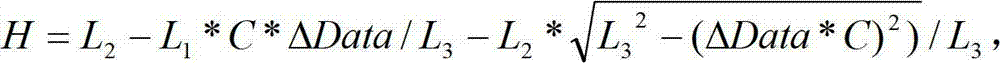

[0026] see figure 1 and figure 2 , an arbitrary triangular sensor involved in the present invention, including a sensor joint block 8, a sensor 6 installed on the sensor joint block 8, an adapter 4 hinged on the sensor joint block 8 through the center of rotation 5, and an adapter 4 arranged on the adapter 4 The measuring rod 3 at one end, the measuring needle 2 arranged at the end of the measuring rod 3 away from the adapter 4; the other end of the adapter 4 is in contact with the sensor contact 7; The rod 3 is parallel and located above the measuring rod 3 . In order to prevent the joint block from colliding with the measured object, it is better to make the bottom surface of the sensor joint block 8 parallel to the horizontal plane and above the measuring rod 3 . In order to change the measurement range so as to realize the measurement of various workpiece ranges, the measuring rod 3 is a plurality of replaceable measuring rods with different lengths.

[0027] A kind of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com