Micro-nano particle reinforced aluminum-based composite material and preparation method thereof

A technology of micro-nano particles and composite materials, applied in the field of aluminum-based composite materials and their preparation, can solve problems such as difficulty in uniform dispersion, and achieve the effects of improving interface wettability, reducing reaction temperature, and increasing flexural strength and Brinell hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 The micro-nano particle reinforced aluminum-based composite material was prepared through the following process:

[0035] Step 1. Preparation of silicon carbide / copper oxide composite powder:

[0036] a. Prepare 0.34mol / L copper sulfate solution A and 20mol / L sodium hydroxide solution B respectively;

[0037] b. Add 50um silicon carbide powder with a particle size of 1:1 to the copper ion in a ratio of 1:1 to the A solution and stir to obtain the C mixed suspension, the stirring time is 15 minutes;

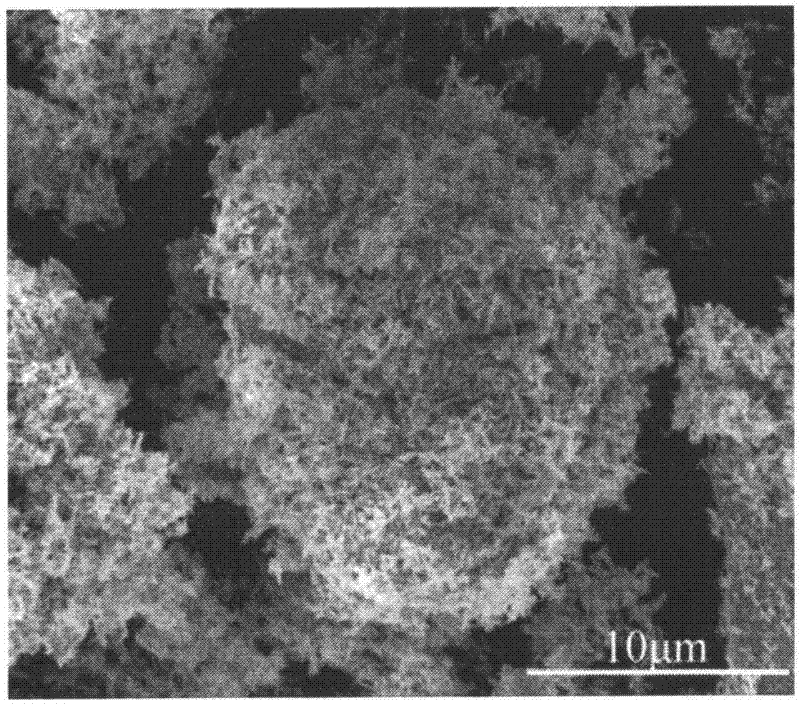

[0038] c. Mix solution B and suspension C to obtain solution D, and stir for 30 minutes at a stirring speed of 100 rpm at a temperature of 20°C; d. Vacuum filter the product in solution D, bake at 150°C for 6 hours, and grind. The composite powder is obtained, the morphology and structure are as Figure 2a , 2b Shown

[0039] Step two, see figure 1 , The use of stirring casting combined with in-situ reaction method to prepare micro-nano particle reinforced aluminum-based ...

Embodiment 2

[0044] The difference between this embodiment and the embodiment 1 is that the reaction temperature when solution B is added to solution C is 30°C. See Figure 3a Under the same conditions, the coating effect at a temperature of 30°C is not as good as that at a temperature of 20°C.

Embodiment 3

[0046] The difference between this embodiment and the embodiment 1 is that the reaction temperature when solution B is added to solution C is 40°C. See Figure 3b It can be seen that the coating effect at 40°C is not as good as that at 20°C and 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com