Manufacturing method of urban energy-saving and environmental-friendly cultivation medium

A cultivation substrate, energy-saving and environment-friendly technology, applied in cultivation, soilless cultivation, botany equipment and methods, etc., to achieve good water retention performance and improve water conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods and features provided according to the present invention are described in detail as follows:

[0026] A method for manufacturing an urban energy-saving and environment-friendly cultivation substrate is characterized in that the implementation steps are as follows:

[0027] The first stage is an addition reaction, that is, urea and formaldehyde undergo a methylolation reaction in a neutral or alkaline medium with a pH of 7 to 8. The reaction process is as follows:

[0028] That is, a hydroxymethyl urea;

[0029] That is, dimethylolurea;

[0030] When the molar ratio (F / U) of formaldehyde to urea is large, the further reaction generates trimethylolurea and tetramethylolurea;

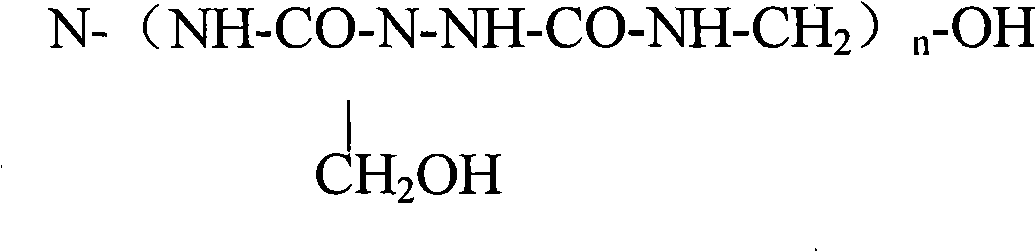

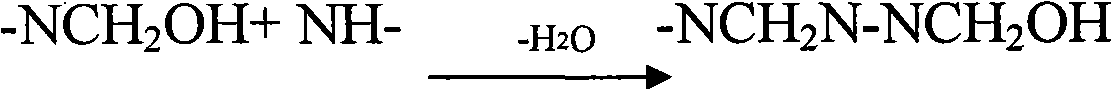

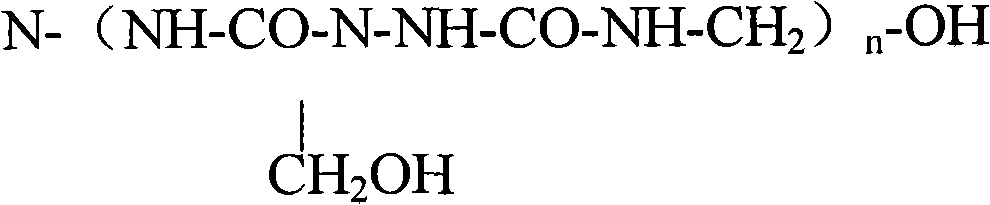

[0031] The second stage is the polycondensation reaction. Under the condition of weakly acidic pH=4~6, various methylol ureas are condensed to form a hydrophilic resin. The struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com