Production method of chassis of railway vehicle

A production method and technology of railway vehicles, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of affecting the assembly efficiency of steel structure underframe components, the inconsistency of design standards and process standards, and affecting corbel beams, etc. Solve problems such as component installation accuracy, achieve good market prospects, reasonable positioning methods, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

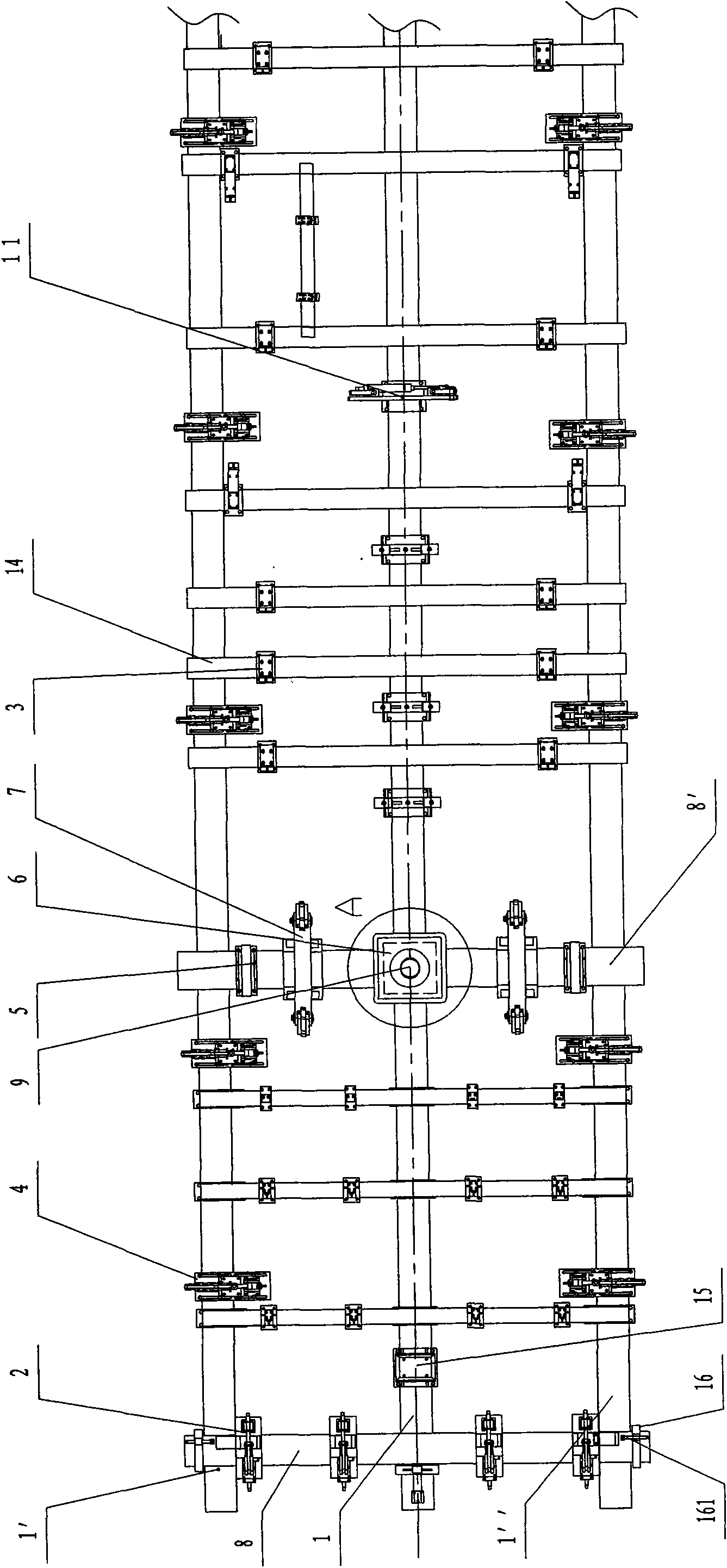

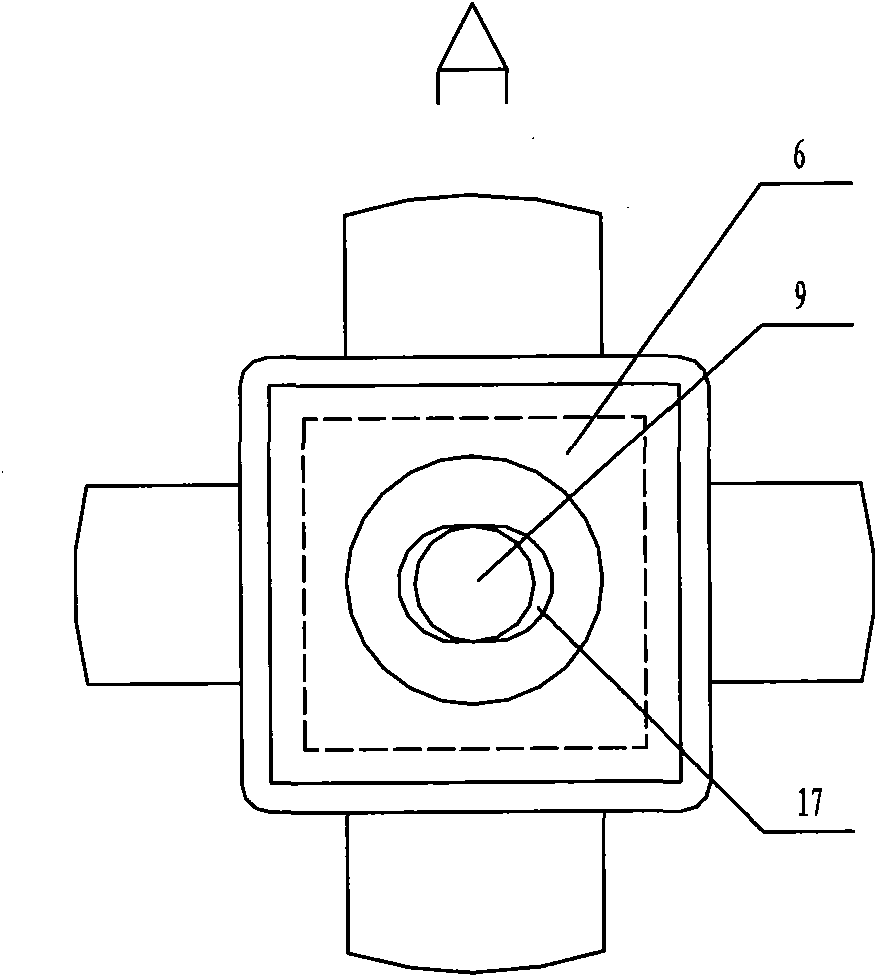

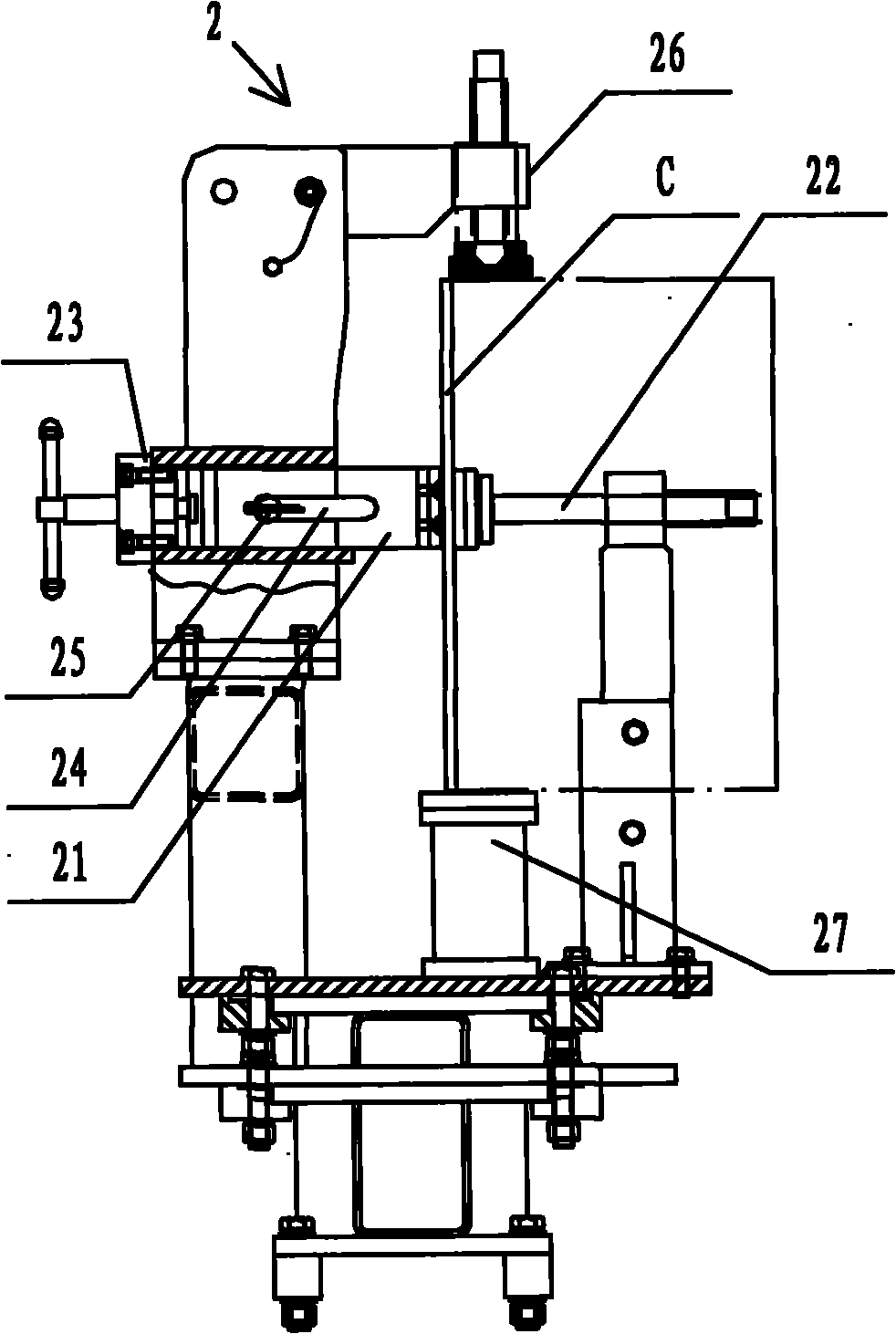

[0038] The railway vehicle underframe production method of the present embodiment is based on such as figure 1The bottom frame shown in the figure realizes the front tire (only the structure of half side of the front tire is shown in the figure, and the other half is symmetrical to its structure). Frames 8, 8', the upper end surfaces of vertical frames 1, 1', 1" are located in the same horizontal plane (flatness is about 1mm), large horizontal frames 8, 8' are perpendicular to vertical frames 1, 1', 1" and can be Arbitrary movement and positioning on the vertical frames 1, 1', 1", the two large horizontal frames 8 are located at the outer ends of the vertical frames 1, 1', 1", corresponding to the end beams of the bottom frame, and the other two large horizontal frames 8' The inner ends of the longitudinal frames 1, 1', 1" correspond to the corbels on both sides of the underframe, and the large horizontal frame 8 at the outer end is provided with an end beam positioning and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com